Flexográfico acquires Kodak Flexcel NX Wide 5080 System from Miraclon

Spanish flexo prepress provider Flexográfico has installed Kodak Flexcel NX Wide 5080 System from Miraclon to gain a foothold in the premium packaging sector. This new acquisition is in line with its ambitions to become a market leader by adopting innovative working methods, investing in new, modern and environmentally friendly technology, and continuous training of its workers.

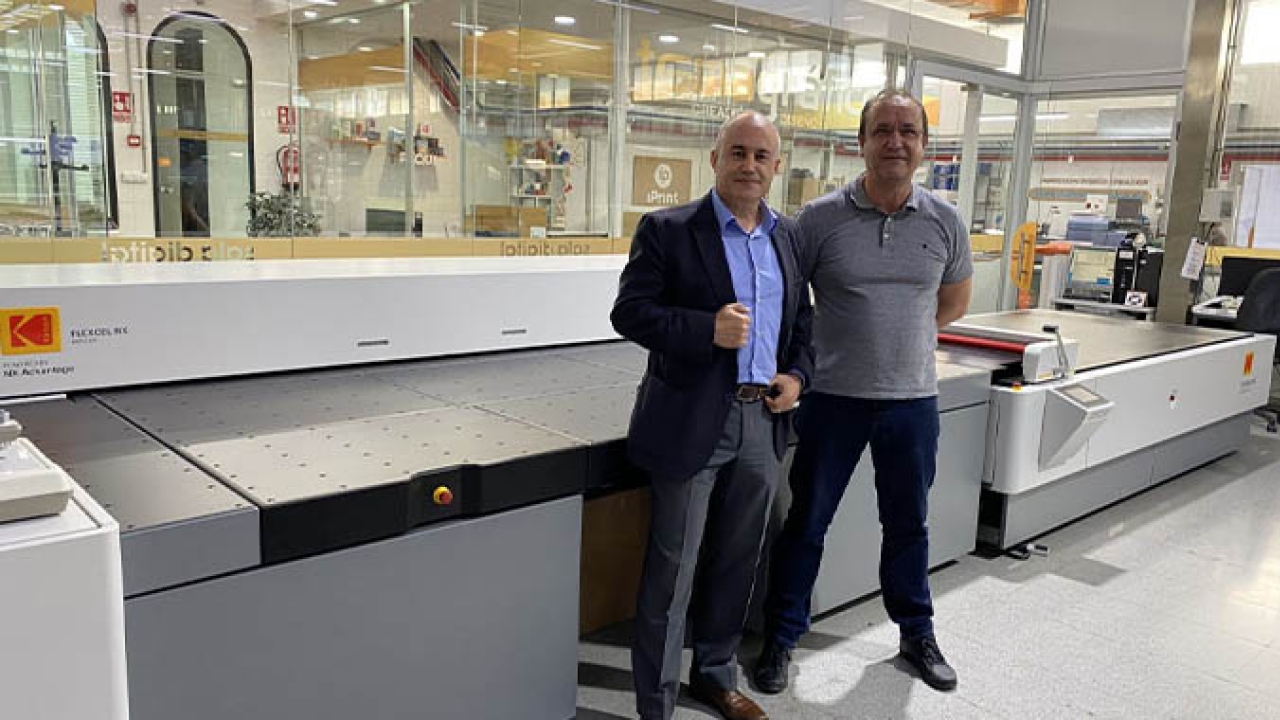

Flexográfico produces all types of flexographic plates, from liquid resin to laminated layer (lams layer). The recently installed Flexcel NX Wide 5080 System will, in the opinion of the company’s founding partners, manager Julián Martínez and technical director, Emilio Zamorano, ‘put us up there among the leading companies at a national level, in terms of production potential as well as the application of state-of-the-art flexographic platemaking technologies.’

Martínez explained that the Flexcel NX Wide 5080 System will allow them to win over new markets and contracts that require high quality with maximum plate sizes of up to 1,270mm x 2,032mm. ‘With this new format, we will be able to offer fine image reproduction, print contrast and high densities, while also saving on plates, waste and production time. For all these reasons, we are convinced that our customers need Flexcel NX plates to compete with the top printers.’

‘We are already completely satisfied with our decision to invest in the Flexcel NX Wide 5080 System, as it immediately opened many doors, allowing us to win new customers. We are confident that it will soon become our best performing plate production line and our forecast is to finish 2021 with 35 percent of our production being carried out on it.’

For Martínez, ‘Kodak SquareSpot imaging technology, which is integrated in all Flexcel NX Systems, offers us the perfect microdot that guarantees the best quality.’ This is possible because the CTP creates a mask for plate production by imaging the Kodak Flexcel NX thermal imaging film (TIL) at high speed and offers semi-automatic loading and unloading.

Before UV exposure and traditional processing, the imaging film is laminated onto a plate, a key process that eliminates the presence of oxygen and ensures the creation of flat-top dots that are a faithful 1:1 reproduction of the original digital file.

Martínez pointed out that with DigiCap NX patterning technology the company achieves ‘excellent’ density range covering the entire color gamut.

Flexográfico manufactures high-tech flexographic clichés and plates for printers in the packaging industry. It has a 3,800 square meters production plant in Paterna, Valencia, that carries out more than 30,000 packaging orders every year for the flexible packaging, label, corrugated cardboard and offset sectors.

The company is made up of a team of 55 professionals, 25 of whom are multi-purpose designers, with more than 40 years of experience in graphic arts. Its clients include large flexible packaging and corrugated cardboard groups such as Saica, Grupo Hinojosa, International Paper, La Plana, DS Smith, Cartonajes Bernabeu, Grupo Petit or Smurfit Kappa and brands such as Nestlé, Danone, Gallina Blanca and El Pozo.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.