GT Etiketten & Labels expands flexo capacity with Mark Andy presses

Dutch label converter GT Etiketten & Labels has invested in two Mark Andy Evolution Series E5 flexo presses with GEW LED/UV capability and ABG Vectra turret rewinders to further expand its capacity.

Gert Talen started his career in 1988 as a flexo printer and throughout the years built a reputation for being a great print problems solver. He is often referred to as ‘Gert the Label’.

Together with his son Luke and daughter Anna, he owns and manages GT Etiketten & Labels based at Schoonebeek on the Dutch/German border, which affords him easy access to the packaging markets of western Europe.

The company, which opened just prior to the Covid pandemic in 2020, occupies a 1,800 square meters factory unit that was fully refurbished prior to the first label being produced in September of that year. With a staff of 15, company sales will exceed EUR 6.2 million in 2023 and is showing a healthy growth rate of 20 percent year on year, working a flexi-shift pattern five days a week.

Beginning life with two used presses, which Gert subsequently sold for a profit, production really got into gear with the installation of the first Mark Andy press in 2022. It was an Evolution Series E3, 8-colour flexo line with 430mm (17in) web width.

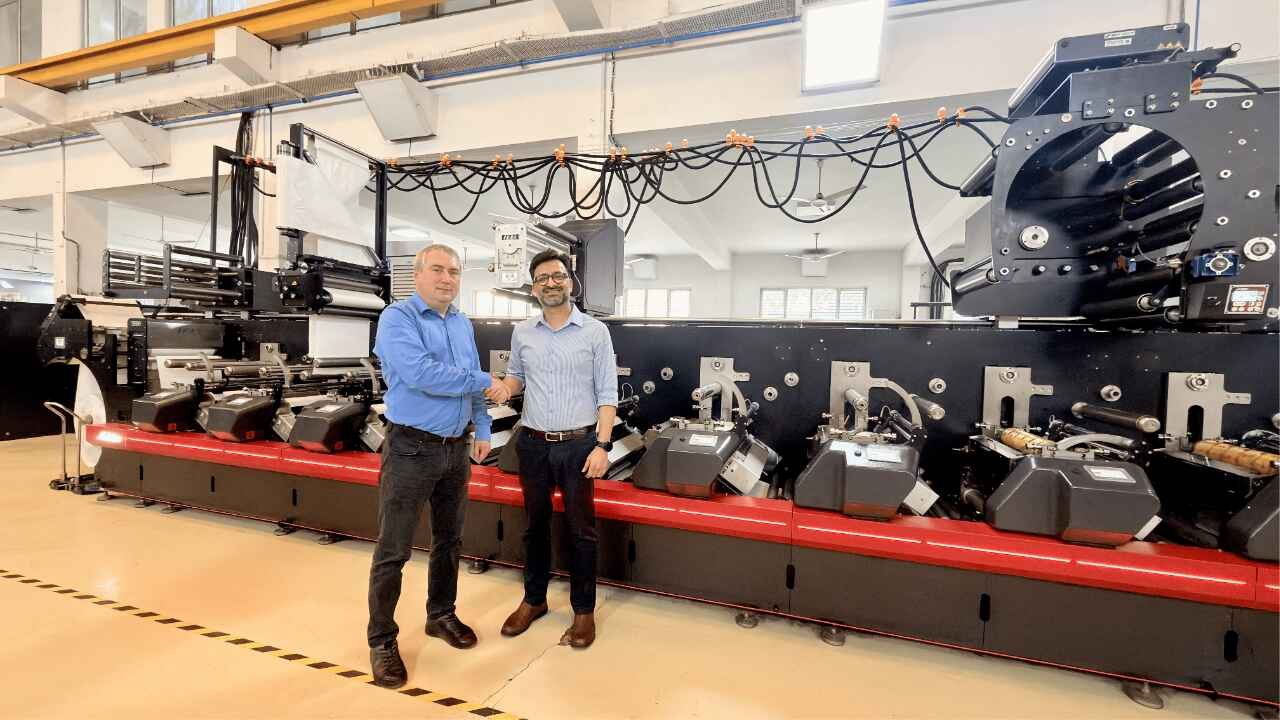

It was followed by two Mark Andy Evolution Series E5 presses, installed in August 2023. Both are 8-colour with 430mm (17in) web width and all three machines now have GEW LED/UV capability fitted with ABG Vectra turret rewinders.

Additional features include Teknek web cleaning and Vetaphone corona treater, delam/relam, turn bars, cold foil, automatic and pre-register capability, die-cutting, a touchscreen interface for BST Powerscope vision system, and a servo driven cantilevered lower rewind with 1016mm (40in) capacity and taper tension.

Maarten van Bergeijk of Packtion, local Mark Andy representative, commented: ‘These are highly capable production tools with a wide substrate range and 230 m/min (750 ft/min) running speed. They will offer GT Etiketten the scope to develop the business in a variety of ways with innovative products for new market sectors if they choose. The company’s production floor is now an excellent showcase for Mark Andy flexo technology in the Benelux region, and we are grateful to the management team for this valued cooperation.’

Around 80 percent of work at GT is produced for the food sector with logistics and pharmaceuticals making up the balance. Currently, the company is printing predominantly on top-coated paper substrates.

‘We are also currently trialing water-wash adhesives that will save around 80 percent of recycling costs over the way the labels are currently produced,’ said Talen. ‘This is good for presentation as more of the product can be seen through the packaging and is especially appreciated by the meat and bakery sectors.’

To add to the company’s reputation for quality work, one of its labels was recently judged best in class by EFTA-Benelux. A four-color flexo label cured by LED/UV and printed on a coated stock for ‘Denner Zartbitter Creme’ chocolate won both the Narrow Web and Food Packaging categories.

Mark Andy sales manager, Timo Donati, added: ‘The Benelux region is an important and fast-growing market for Mark Andy where we have enjoyed great success with our flexo and hybrid presses in recent years. In fact, we have the most installed LED/UV label presses there, which is a tribute to our sales and support personnel as well as the capability of the technology to earn money for its users. GT Etiketten is a great example of that, and we prize them highly as a customer.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.