GTV invests in South Africa’s first EcoLine 340

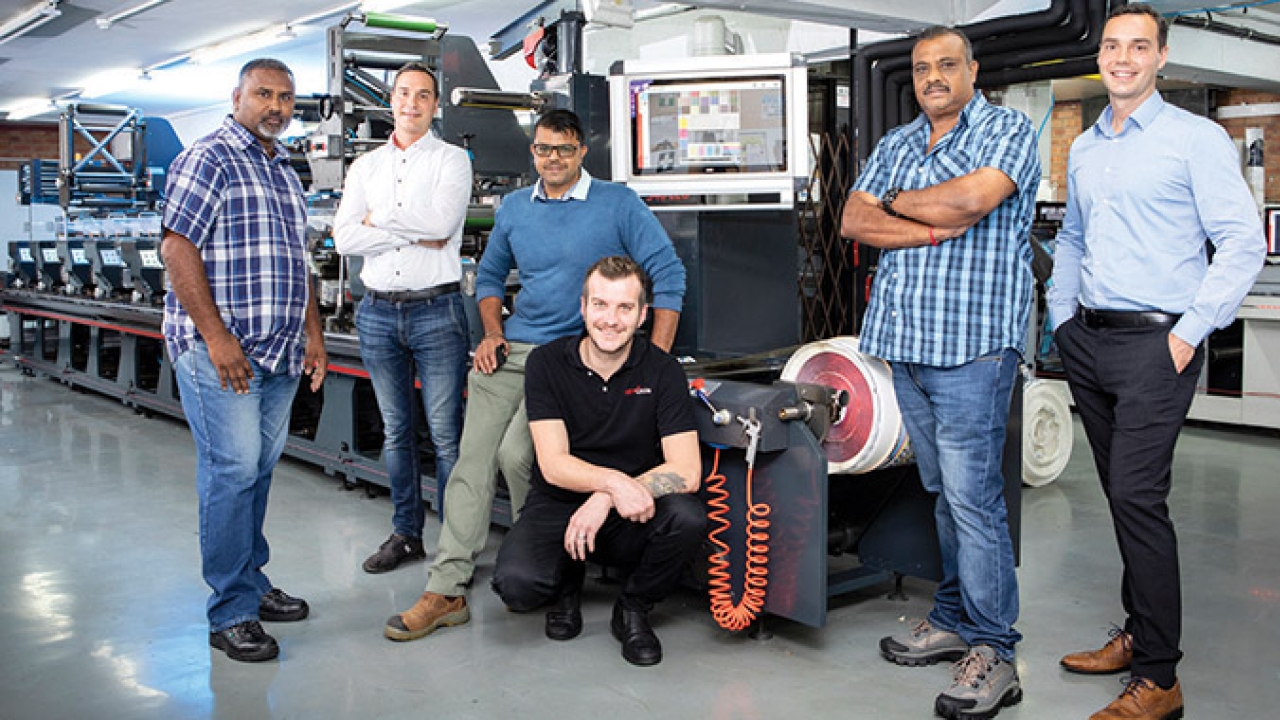

GTV Label Master, a Durban-based label converter, has invested in South Africa’s first Rotocon EcoLine RFP 340 flexo press and EcoLine Pro Mount plate mounter.

The newly installed press features Yaskawa’s latest servo drive and control system, while each printing unit is driven by a separate servo motor. These units are designed for optimal ink transfer and pressure adjustment to guarantee crisp-dot printing in high line counts, text, linework, solids, adhesives and varnishes. If fine-tuning is required, it can be performed simply by adjusting the corresponding pressure setting device on both sides.

‘The BST web inspection system also ensures high-quality during the printing process,’ added Pascal Aengenvoort, director of Rotocon. ‘The lightweight aluminum print cylinders feature a high precision helical gear transmission for high accuracy. This design ensures that installing the cylinder in the print head is a smooth and easy operation. The LED UV curing system ensures an improved energy footprint across the short web path. The filmic material isn’t affected by the UV curing temperatures during printing, thanks to a water chiller system linked to the impression cylinder.’

The unwind unit is equipped with a corona treater, dust cleaning unit, and static system to ensure maximum printing stability.

‘After working with Rotocon for many years, and successfully using its EcoLine slitting, inspection and rewinder systems and digital printed label converting and finishing systems, it was a no-brainer for us to invest in the RFP 340 flexo press,’ commented Colin Naidoo, factory manager at GTV Label Master. ‘The press was running immediately thanks to the simplicity of its design and the ease-of-operation, which enabled the operators to adapt easily.’

‘Investing in the RFP 340 and the Pro Mount at the same time has eliminated the need for making brackets to use on existing plate mounters. The RFP 340 requires a different way of mounting plates and the Pro Mount, which is also user-friendly, enables mounting of flexo plates on different cylinders without changing brackets. The after-sales support we receive from Rotocon has always been at the highest standards; plus spare parts are readily available, which helps prevent any downtimes,’ concluded Naidoo.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.