Macaran installs Gallus Labelmaster 440

US converter adds a 14-color Gallus Labelmaster 440 from Heidelberg to provide its customers with greater options for label design

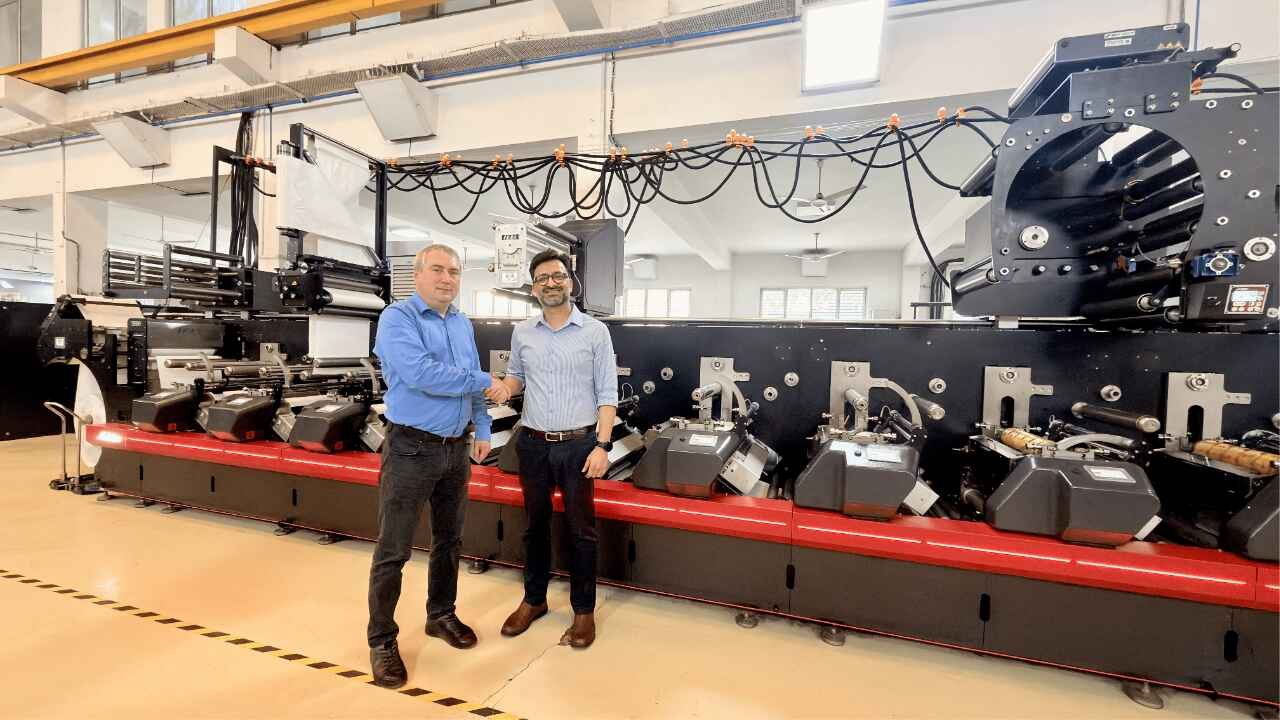

Cohoes, New York, based label converter Macaran has installed a 14-color Gallus Labelmaster 440 from Heidelberg to provide its customers with greater options for label design.

The company, that produces labels for the spirits, craft beer, beverage, food, health/medical, and durables markets, was increasingly challenged by its customers to produce 11, 12, and even 13-color labels.

Prior to the June 2022 installation of its Labelmaster 440, the production team at Macaran felt, at times, restricted by the company’s older press technology.

‘We wanted to do more to help our customers enhance their brand images,’ said Tom Sargent, president of Macaran. ‘As custodians of our customers’ brands, we are now better equipped to produce virtually any label they design.’

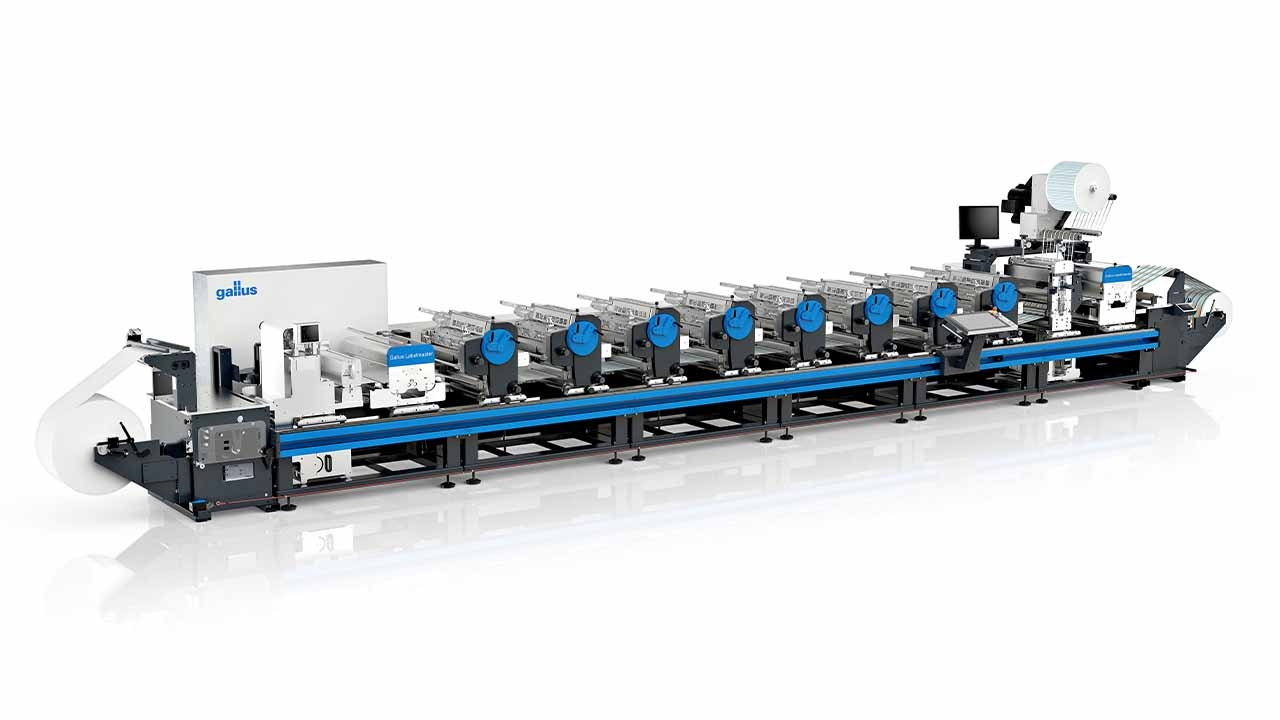

The Labelmaster, capable of printing up to 14 colors with precise color-to-color registration, is helping the company, that recently merged with Syracuse Label, to deliver high-quality, consistent products. According to Sargent: ‘The labels we print are a direct reflection of how our customers are perceived in the market. The Labelmaster ensures reliability across every project, every time.’

Replacing two presses of competitive technology, the Labelmaster has a wider print area of 440mm (17in) for inline flexographic and screen printing in addition to cold foil and embossing embellishments. Previously only capable of printing up to 11in wide, Macaran believes the Labelmaster will not only help gain additional work with its current customers but also attract new customers.

‘We knew we needed to upgrade our press technology,’ said Nick Noyes, chief operating officer, Macaran. ‘But we also needed additional width capabilities in order to grow the business.’

With an extremely short web path (only 1.1m between printing units), the Labelmaster produces minimal waste thanks to the short set-up times and stable register accuracy.

Noyes added: ‘Gallus has done a great job efficiency wise on how changeovers happen and how everything runs. It all seems to fit together really well.’

Macaran’s new Labelmaster, which runs over 400ft/min, is a speed upgrade from its previous presses. Since installation, the Labelmaster has drastically increased the company’s productivity, thus boosting its overall throughput – giving the company additional capacity to take on new work.

While the additional capacity is significant to Macaran’s future growth, Sargent said: ‘We’re really focused on our enhanced capabilities. The Labelmaster allows us to offer extended branding opportunities to our customers to deliver better brand messaging for the consumer.’

Further enhancing the quality of its labels, Macaran uses Gallus Screeny products for its rotary screen embellishments. The unique microstructure fabric and photosensitive coating ensure maximum consistency for extremely fine lines, solids and relief printing.

Switching from competitive technology, Macaran made the decision to go with Gallus based on its reputation for efficient flexo-screen combination printing.

‘After we ran the ROIs, looked at what machines we could retire, and what efficiencies we could hit, it was a no brainer,’ Noyes concluded.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.