Malmesbury Labels makes digital investment

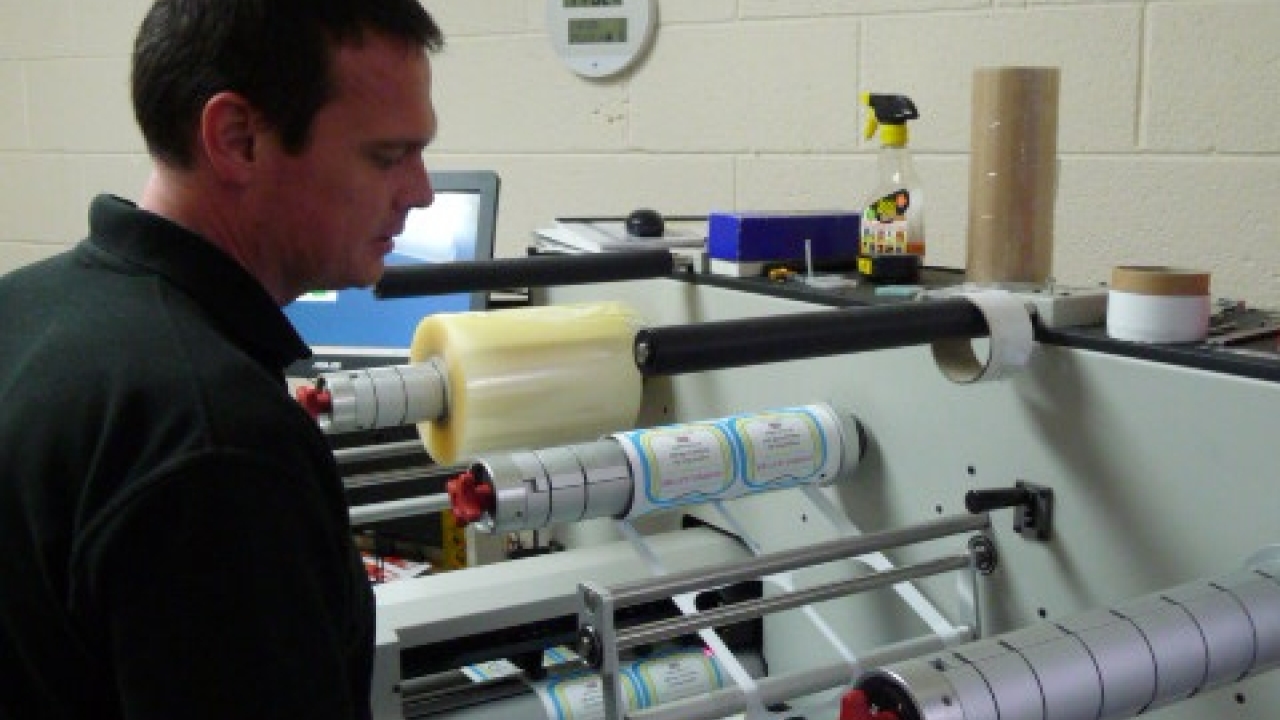

UK flexo printer Malmesbury Labels, based in Cirencester, Gloucestershire, has made its first investment in digital with the installation of an Allen Datagraph Systems iTech Centra HS label system to produce cost-effective 4-color labels in smaller quantities for its customers.

Malmesbury Labels manufactures and prints self-adhesive labels for a wide range of applications, from food and drink products to general packaging and labeling, typically printing on paper and synthetic materials with adhesives to match label requirements.

Its press portfolio includes 3- and 4-color flexo presses, and its orders range from longer runs of 40-50,000 labels to 6-8,000 spot color labels.

In order to better meet the requirements of its customers, Malmesbury Labels took the decision to invest in a digital printing system to bring down the cost of producing small runs, and was looking for a complete system if possible. It considered the expenditure too high to be viable for larger systems, and said many of the more economical systems could not print accurately on pre-cut media. It also reported that some of the analog cutters had problems with digital printing.

The iTech Centra HS digital label system manufactures label runs of 300-900 linear meters of roll substrate. It produces fully finished labels, in any shape without dies, fitting the needs between table-top label production and full-scale production.

The system combines the iTech Centra HS digital label printer, which is an LED toner printer that images consumer-quality labels at 1,200 x 600dpi at speeds up to 9.1m/min, with the iTech Centra HS digital label finisher, which is a high-speed roll-to-roll digital finishing system that lets users laminate, die-less cut, strip the waste matrix and slit custom labels in one production pass.

Howard Burr, Malmesbury Labels managing director, said: ‘Much of our work has been for retail businesses. These boutique businesses will use carry bags with cord handles to promote their company and products. We create the labels for them.

‘The challenge is that many 4-color label jobs come with new artwork, and are likely to be run only once. To create the labels and pay £150 for four plates and for dies to manufacture runs of 1,000 is too expensive. It’s why we decided to invest in a digital printing and finishing system.

‘We have been running the iTech Centra HS digital label system for three months. It turns around multi-color work very quickly, and can cut any shape or size.

‘A lot of the jobs we produce on the Centra HS are much more viable than our only other option – flexo. Normally we would have to take artwork and send it to the platemaker. Now, we get the artwork, add die lines and we’re good to go.’

An example project has been the creation of limited edition beer bottle labels inspired by graffiti artist Banksy.

Burr added: ‘Technology is shifting so rapidly. In the Centra HS we saw something we needed now – a digital capability. We can produce a 4-color label within a day or so. The Centra HS has an attractive ROI, and offered us easy entry into the market. It is fulfilling our requirements.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.