Scanbag installs Flexo Wash laser cleaner

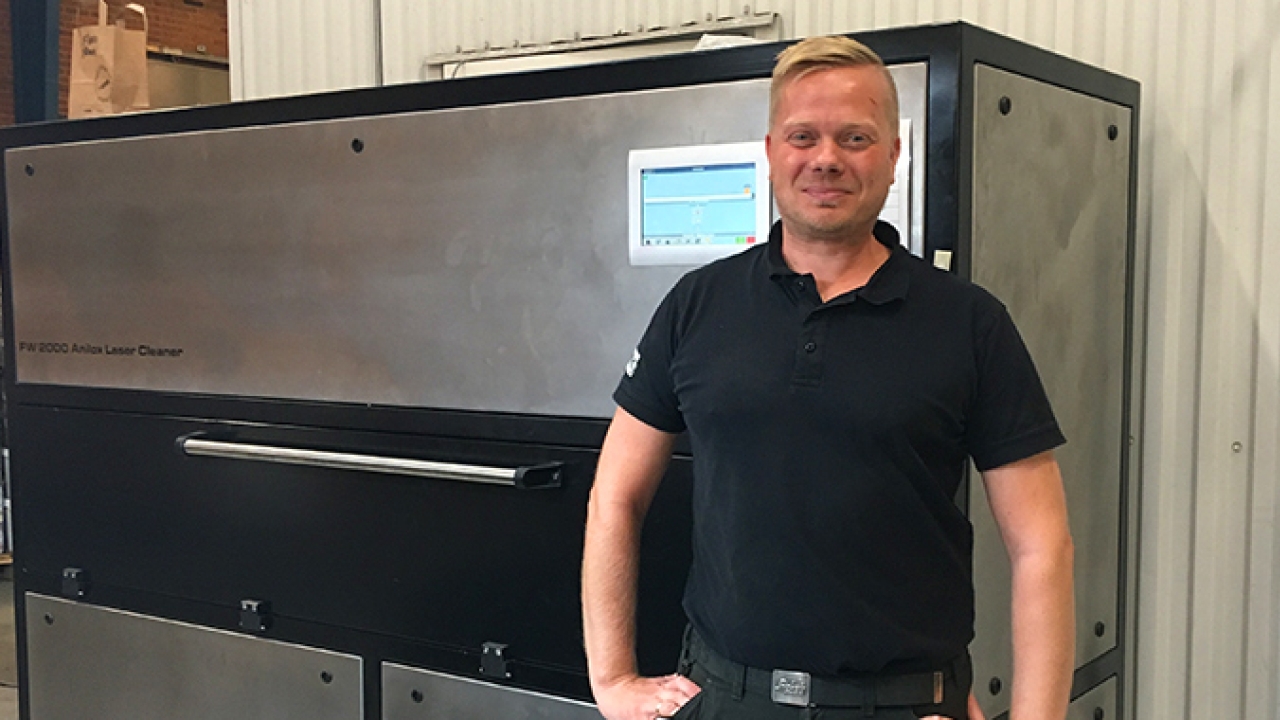

The Danish converter Scanbag has installed a laser anilox cleaner from Flexo Wash FW2000 at its production plant in Skive.

The FW2000 model was introduced in 2018 as the first laser cleaning unit in the Flexo Wash cleaning range. The new laser technology is suitable for 100 percent cleaning without damage to the costly rolls, with the guarantee of consistent print quality and reduced downtime.

‘We are very satisfied with the cleaning results and the easy handling of the

‘For us it was important to develop a Laser Anilox Cleaner with as much safety as possible. The ceramic on the anilox rolls is very delicate and can easily be damaged when cleaning with a laser, so safety is extremely important,’ added Anders Kongstad, technical director at Flexo Wash.

The new Flexo Wash laser cleaner sits well with the company’s ethos of quality, safety and focus on the environment. It is easy to load, with the anilox rolls placed into a drawer and then slid into the machine, the FW2000 monitors all aspects of the anilox including cell depth,

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.