Solopress invests in Konica Minolta’s new Motioncutter 23

Solopress has become the first UK customer to receive and use the new Konica Minolta Motioncutter 23 to cut, kiss cut, engrave, perforate, crease, and personalize in a single pass.

With a pre-pandemic turnover of over 30m GBP, Solopress, based in Southend-on-Sea prints and sells around 1m GBP of bespoke labels and stickers a year. The company was enjoying growth in demand and was looking to expand its production capabilities by investing in a suitable laser cutting technology.

Beforehand the company had used pre-kiss cut and fixed-sized labels to print on, but this had proven to be time-consuming to prepare and limited production flexibility and efficiency, making it more of a challenge to react quickly to customer demands.

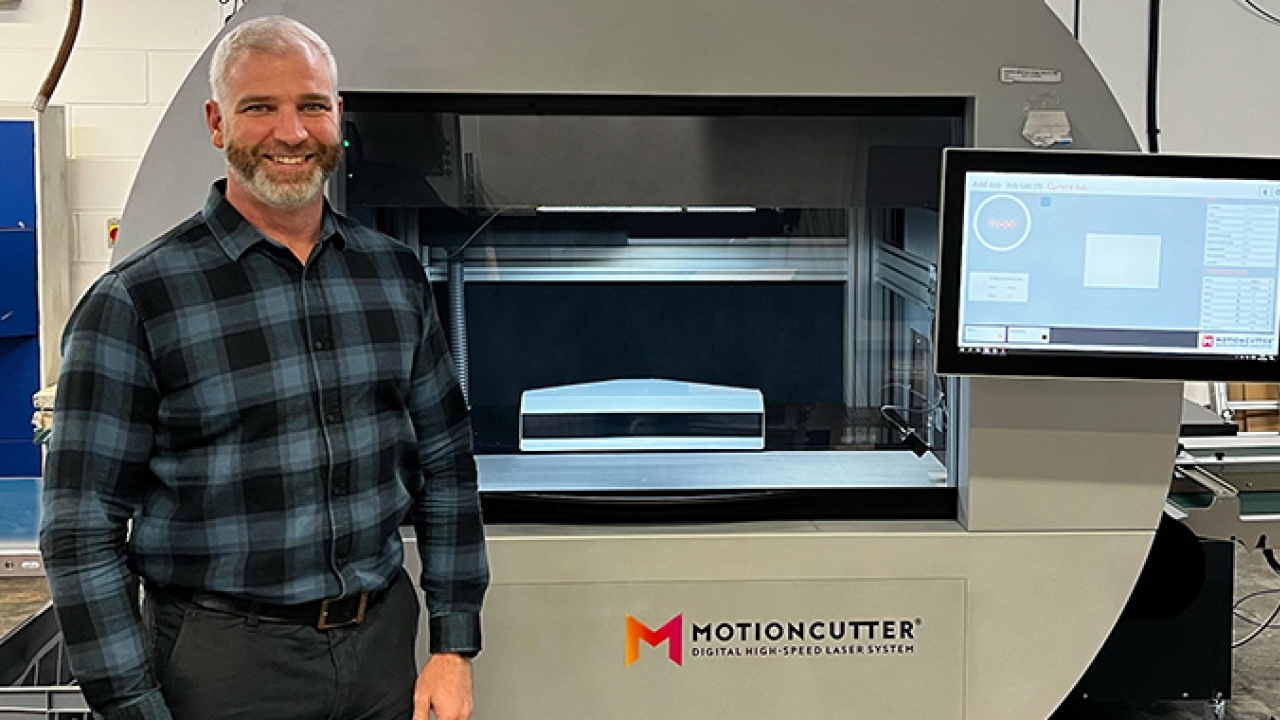

‘Having seen the impressive results and the potential for big material cost savings, we felt the Motioncutter 23 was a no-brainer for us,’ commented Simon Cooper, managing director of Solopress. ‘We estimate that the CapEx costs of the machine will be offset within just 18 months, while the operational benefits will be realized right away. Having had a productive year in 2021, we were keen to invest this back into the business right away, so we were delighted that Konica Minolta was able to deliver on its promises so quickly.’

The Motioncutter 23 has reduced Solopress’s stock management needs and associated costs, enabled catering for any shape, size, or quantity of labels by stocking a selection of popular print materials.

‘This flexibility is ideal for a range of clients,’ added Grahame Megilley, industrial print business development manager at Konica Minolta Business Solutions (UK). ‘Solopress can supply high-quality labels to a broad range of customers, from printers and resellers to graphic design businesses and (significantly) smaller microbusinesses and home-based businesses that produce very bespoke individual products that require short runs of labels – something which is often lacking in the market but in high demand post-pandemic. For example, it is the perfect solution for the needs of artisan food and drink producers that need highly bespoke labels, often with very short lead-times.’

Sold exclusively in the UK and Europe through Konica Minolta, the Motioncutter 23 now provides Solopress with an automated technology featuring barcode job recognition, camera positioning, and software-controlled waste separation.

‘We can now reduce our stock while at the same time delivering our customers more options and choices. This really is the perfect solution for our ever-evolving business,’ concluded Cooper.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.