Accraply introduces modular upgrade for Trine roll-fed labelers

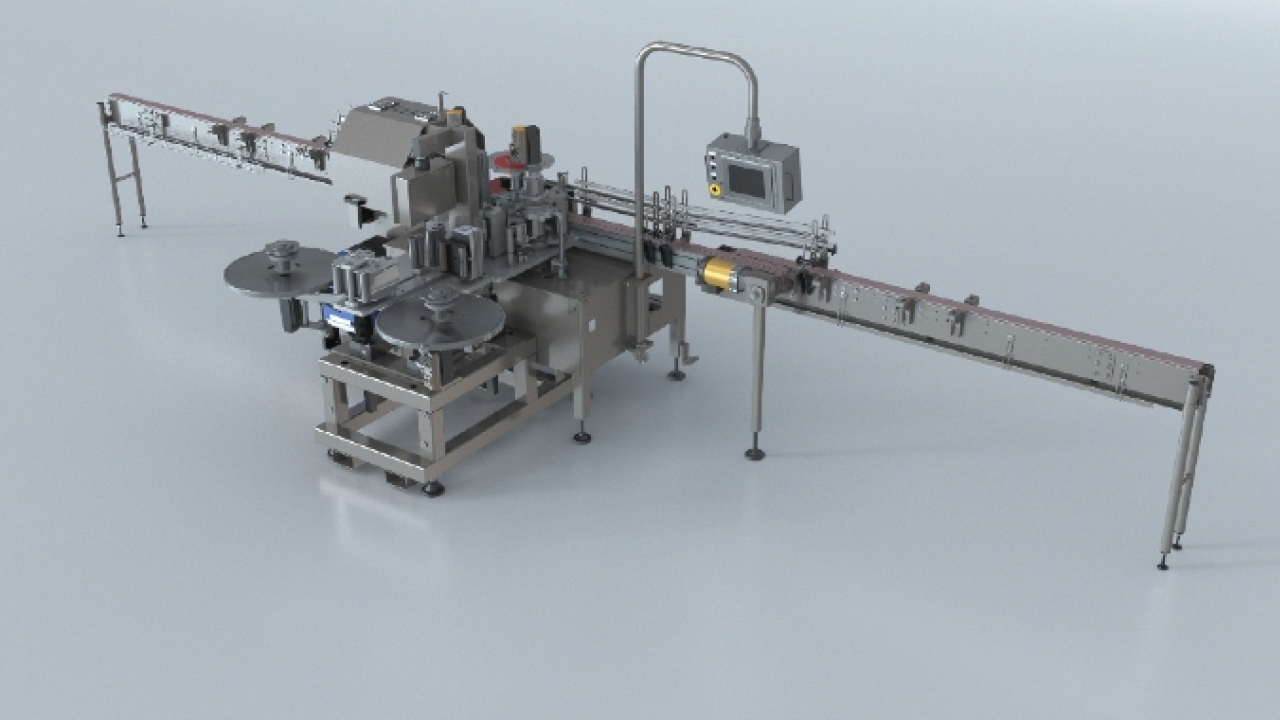

Accraply, a worldwide supplier of label application systems, has introduced the Trine Modular Labeling Station, an upgrade for existing Trine roll-fed labelers that enables significant process improvements with minimal line disruption. Designed to integrate quickly and seamlessly with existing Trine labelers, according to Accraply, this upgrade was engineered to improve throughput, simplify changeovers and operation, reduce maintenance costs and improve label appearance.

The Trine Modular Labeling Station can be retrofitted to an existing Trine labeling system or be used with a new Trine system. This was designed to satisfy the evolving requirements of Accraply’s Trine customer base.

‘This innovation is based exclusively on feedback from our customers who are already using Trine labeling systems,’ said Troy Peterson, Accraply’s Trine product line leader. ‘We are excited to bring this modular and easy-to-install solution to the roll-fed label market.’

To mitigate costs and line disruption, this upgrade leverages the customer’s existing product handling system and existing Trine change parts. It can be installed in as few as three days, bringing upgrade to the customer’s operations quickly while minimizing downtime.

The labeling station includes Accraply’s SmartLink HMI, a controls platform with efficiency reporting, preventative maintenance alerts, self-diagnosing software, video tutorials and onboard parts ordering. This HMI simplifies operation and increases throughput. It also decreases setup time by eliminating variables and opportunities for operator error.

According to the company, the Trine Modular Labeling Station also includes improvements to maintenance, safety and waste reduction. The large diameter glue roll eliminates glue slinging and reduces vacuum drum cleaning time by 50 percent. The glue roller and glue scraper systems are safe, easy to keep clean and provide simple setup. The self-timing, servo-driven system includes fewer moving components and wear parts than previous Trine labelers, reducing the need for replacement parts and operator adjustment.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.