Domino launches Cx350i piezo inkjet technology

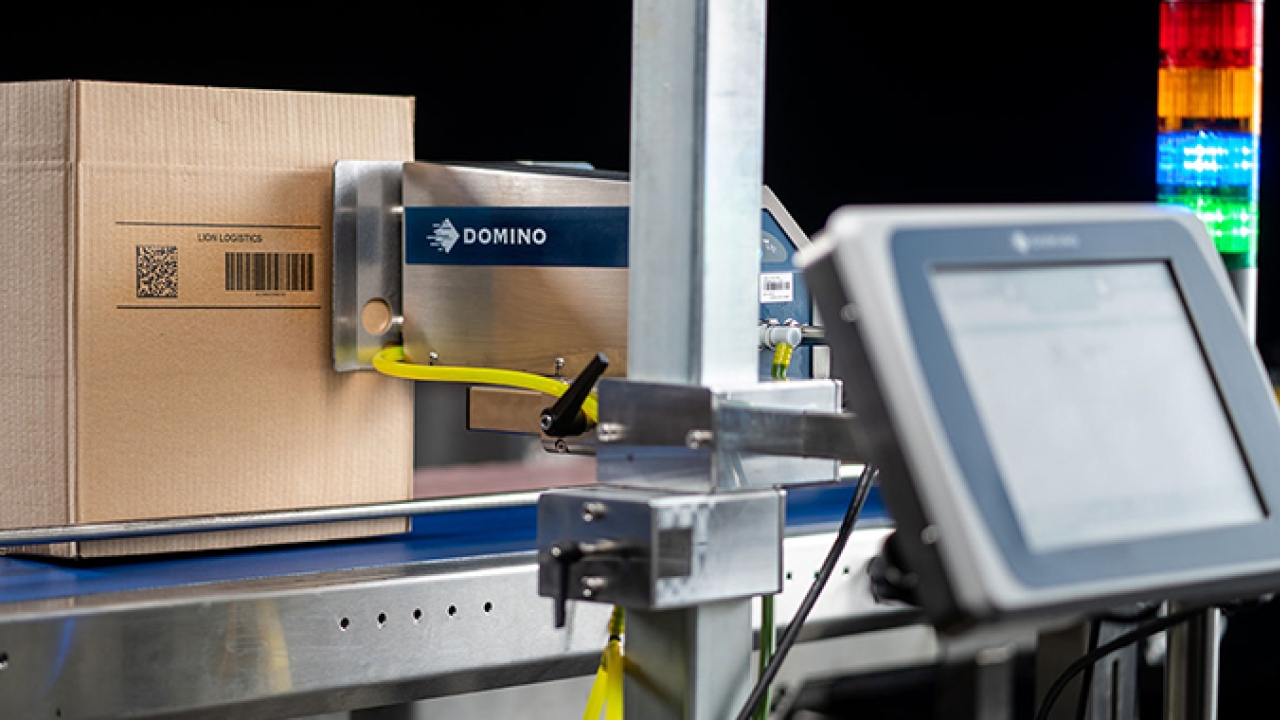

Domino has launched Cx350i, a new sustainably designed piezo inkjet technology for printing on secondary packaging, highlighting its commitment to ‘Do more’ to help manufacturers achieve their sustainability goals.

‘We recognize that sustainable production cannot be achieved in isolation,’ said David Edwards, product manager, PIJ at Domino. ‘Product coding and marking is an integral part of all global supply chains – and as such, we have an ambition and a responsibility to our customers, and to the world in general, to ensure that our products are consciously designed to minimize their environmental impact.

‘The Cx350i has been designed with these ambitions and responsibilities in mind – it offers our customers a sustainable solution for direct printing on boxes and sets a new standard for product development at Domino. The printer is optimized to ensure maximum code quality with minimal ink usage. It has been designed to work exclusively with low-impact vegetable-oil-based printing inks – the result is sustainable printing without compromising quality.’

According to Domino, the Cx350i has been optimized to achieve a 33 percent reduction in ink usage for barcodes printed at 200 DPI compared with Domino’s previous generation secondary packaging printers.

‘While resolution relates only to the number of ink dots per inch, overall print quality is also determined by ink drop size, drop placement, and the ink itself,’ added Edwards. ‘With the Cx350i we worked to optimize all the factors which influence print quality – improved drop size and ink placement – and new and improved inks have allowed us to reduce the overall quantity of ink needed to produce high-quality codes time after time.’

‘While resolution relates only to the number of ink dots per inch, overall print quality is also determined by ink drop size, drop placement, and the ink itself,’ added Edwards. ‘With the Cx350i we worked to optimize all the factors which influence print quality – improved drop size and ink placement – and new and improved inks have allowed us to reduce the overall quantity of ink needed to produce high-quality codes time after time.’

The Cx350i requires less frequent purging than previous piezo inkjet printers, which further reduces ink waste. The printer also offers flexibility regarding printer settings, with options to further minimize ink usage depending on specific customer requirements. Customers can choose from a large range of text fonts and sizes and have the freedom to reduce ink drop size manually.

Domino supports a move away from mineral-oil-based inks and, as such, is investing in sustainable alternatives to mineral oils, including vegetable-oil-based options, for all current and future product development. The new vegetable-oil-based printing inks for the Cx350i comply with current proposals for mineral oil regulations outlined by the German Federal Ministry of Food and Agriculture.

‘You might think that sustainability would come as a compromise to performance – however, this is not the case,’ said Edwards. ‘Our new ink offers premium results in terms of contrast and adherence and has been through extensive field testing to ensure optimal longevity so manufacturers can be sure of a high-quality code which will stand the test of time.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.