Futec introduces machine learning capabilities for fault detection

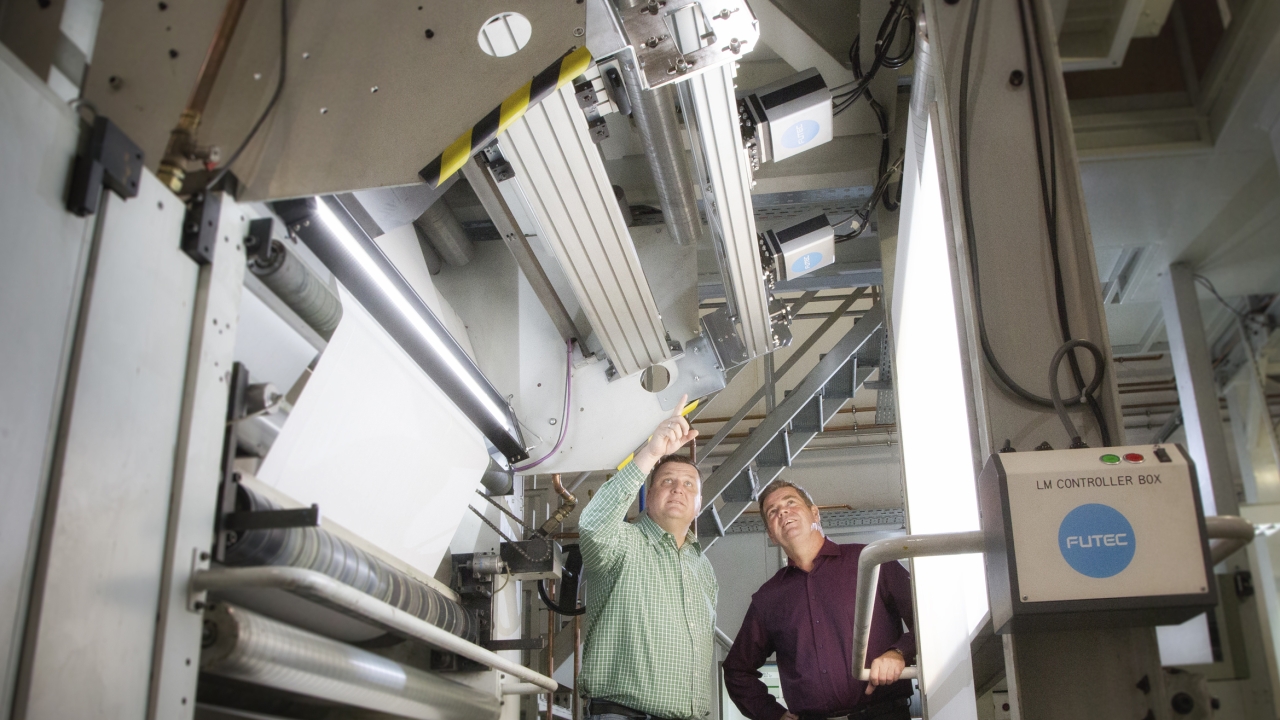

Futec, a specialist in 100 percent inspection for commercial, packaging and label printing markets, has developed machine learning capabilities for fault detection, said to represent the next generation of quality control specifically for flexo printing.

Futec’s hardware-based image processing technology offers ‘the highest processing speed available on the market’, it is claimed, enabling real-time availability of large amounts of inspection data. Now, using sophisticated algorithms to intelligently analyse and interpret the data, Futec can bring significant improvements and efficiencies in key areas for flexo printers: splice detection, pressure control and CI drum inspection.

Futec software enables patterns to be identified in real-time, and the system is able to quickly and clearly distinguish between a printing defect and a machine defect. With ‘Industry 4.0’ in mind, these new benefits enable swift troubleshooting as well as avoiding unnecessary disruptions in production, therefore helping printers transform their businesses.

This development coincides with the installation of the 10,000th Futec system at Schröder Design Verpackung in Germany.

Silvio Neumann, Futec general manager, EMEA, commented: ‘This exciting news comes at the same time as important breakthroughs we have made with machine learning in the flexo space, representing the next generation of 100 percent inspection. We believe this innovation will be revolutionary in helping our customers to be more profitable and allow them to achieve greater efficiencies at the same time as guaranteeing quality.’

These new machine learning capabilities will be available from Futec later in 2018.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.