Global Graphics adds online inkjet screening service

Global Graphics has introduced an online screening service for press vendors and their customers that allows inkjet presses to be calibrated with a simple upload.

Powered by PrintFlat, a technology launched last year to smooth out printhead non-uniformity or banding, the www.printflat.com portal will generate a customized calibration that will mitigate the banding that occurs when a print bar is first built and also as inkjet heads begin to wear or are replaced.

Users of the service simply upload a scan of the print bar to the web site via their user account and PrintFlat works behind the scenes to generate a correction that can be applied directly to the press by the ScreenPro screening engine.

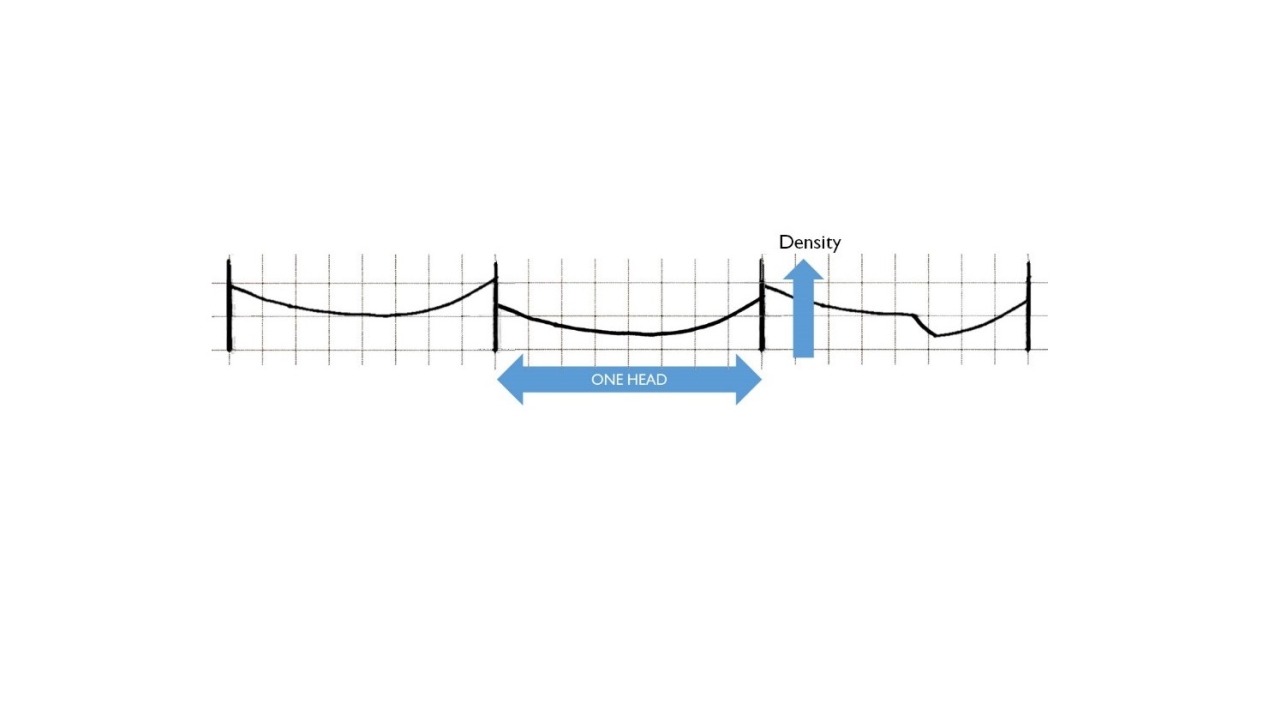

PrintFlat was introduced as part of the ScreenPro v2.0 screening engine. ScreenPro with PrintFlat technology reduces non-uniformity, commonly known as the inkjet smile.

Martin Bailey, chief technology officer at Global Graphics Software, said: ‘PrintFlat.com introduces a step-by-step process for calibrating an inkjet press. It can work with any press that has the ScreenPro engine installed. That means that any press vendor and their customers can benefit because ScreenPro can be applied to any print industry workflow, either to a press that is already on the market, or one that’s still on the drawing board. It can be used with any RIP software and any combination of inks, substrates, printheads and electronics.

‘So just as you would apply color management to your press, now vendors and their customers have a process for applying calibration that mitigates reduces non-uniformity across the web, which can be difficult and expensive to correct mechanically.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.