Kodak launches Flexcel NX Ultra Solution

Kodak has launched the Flexcel NX Ultra Solution, a solvent-free, VOC-free, water-based system that can deliver a press-ready plate in less than an hour and sustain clean, consistent plates in a high-volume production environment.

Chris Payne, president, Flexographic Packaging Division and vice president of Kodak, said: ‘Kodak Ultra Clean technology has solved the fundamental challenge of inconsistency traditionally associated with aqueous processed flexo plates and will enable printers to take advantage of our industry-leading plate technology without the hassle of solvent processing.

‘The Flexcel NX Ultra 35 Solution is the first product to be commercialized from the Ultra NX technology demonstration that we previewed at drupa two years ago and has undergone extensive customer beta trials in demanding production environments. We’re passionate about bringing robust technologies to market and extremely encouraged by the positive experiences of our early adopters.’

Beta-testing sites

Matt Gauthier, pre-press and customer service manager for the Label Division of G3 Enterprises, a wine label operation in California that switched from thermal plates to Flexcel NX plates a number of years ago, said: ‘We can do essentially anything we want print-wise with the Kodak plates but it’s also important to be able to quickly produce an individual plate, especially when we have customers in-house for a press check. It’s been great to have NX Ultra in place, providing the same quality level but requiring much less time to produce a plate. We can make changes and quickly send new plates to press, assuring that customer timelines are satisfied. We have been very happy with results from NX Ultra.’

‘We have a green initiative in our facility,’ explained Rob Anderson, director, production and planning, IGT, a lottery ticket printer based in Florida. ‘So, knowing that NX Ultra was to be a water-wash product and we wouldn’t have to deal with solvent-based processing, it was very appealing to us. The operators of our flexo presses really appreciate the Kodak plates. They see the difference in the dots and how they print and how vignettes, our fine screens, how everything looks so much cleaner and essentially it has made their job much easier. The NX Ultra product itself has been all that has been promised. We can get plates much faster and we’ve accomplished our green initiative. We truly look at Kodak as a partner.”

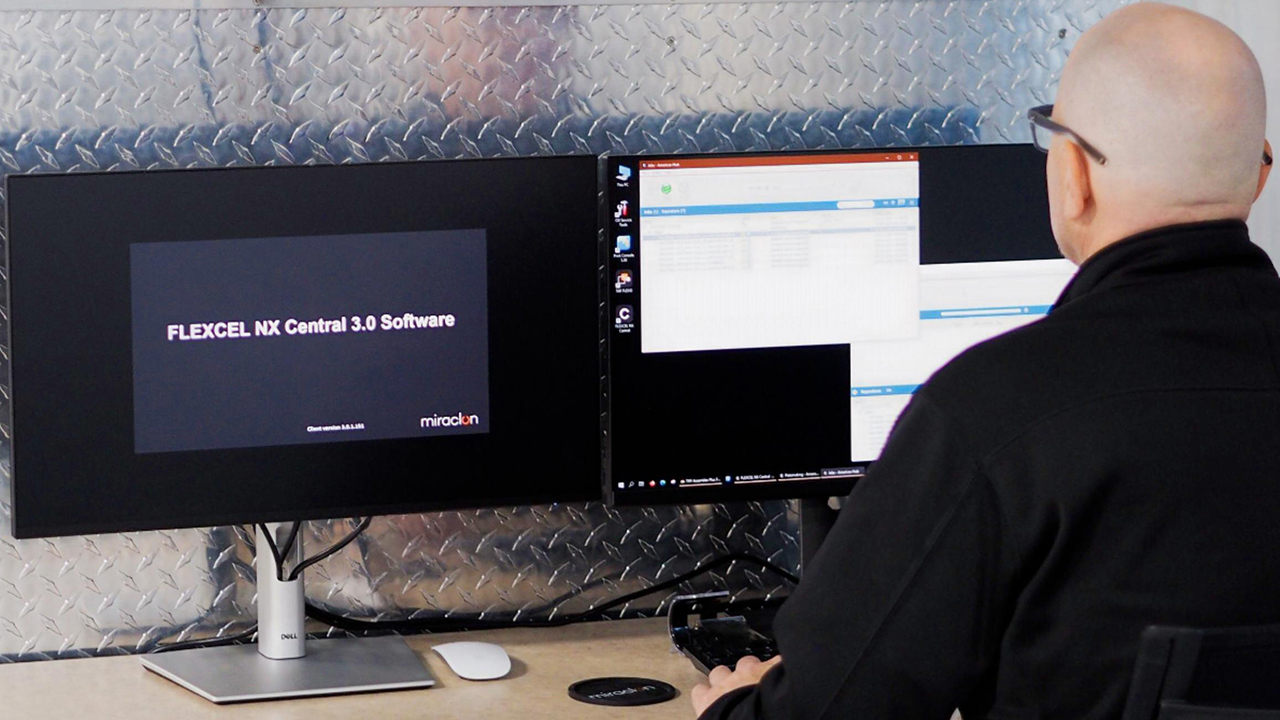

The Kodak Flexcel NX Ultra Solution includes the Flexcel NX System for imaging paired with the new Flexcel NX Ultra Processing System and new Flexcel NX Ultra Plate, delivering a complete end-to-end plate making system. The all-in-one processing system combines exposure, washout, drying and finishing in an easy-to-use, robust system with automated cleaning cycles.

Flexcel NX Ultra Plates utilize the Kodak flat top dot structure and are fully compatible with Kodak’s NX Advantage technology and patented Advanced Edge Definition. The plates will be available in thicknesses of 1.14mm and 1.70mm and are suited to label, paperboard and flexible packaging applications.

The first product to be made available will be the Kodak Flexcel NX Ultra 35 Solution, which can produce plates up to 35in x 48in (889mm x 1219.2mm) in size. Product is due to ship in the first quarter of 2019, initially for the North American market.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.