Perfect Proofer makes European debut at Labelexpo

A tabletop proofing system that provides precise flexo color predictability, without the need for fingerprinting, has been made available in Europe for the first time during Labelexpo.

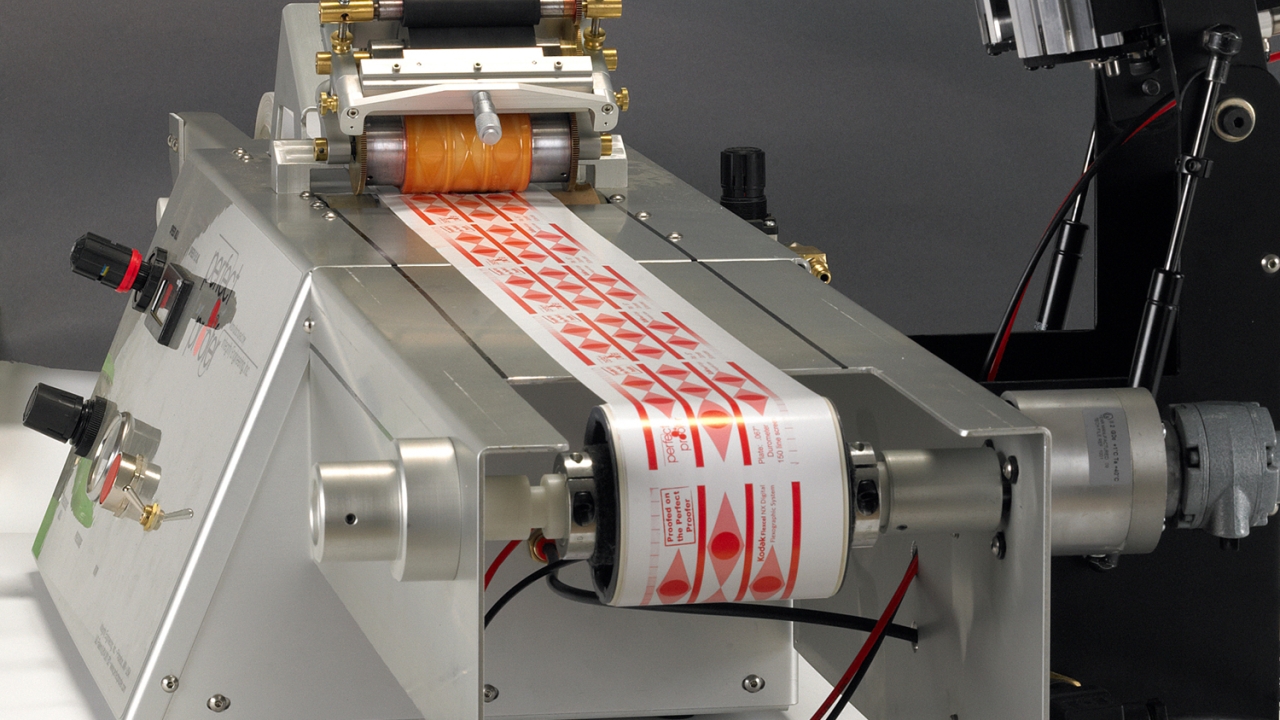

The Perfect Proofer, manufactured by US-based Integrity Engineering, is an automated wet-proofing system that lets ink lab technicians pre-flight their formulations under actual press conditions. Several of the proofer’s key features are identical to these of the target press, including photopolymer plate, tape materials, anilox type and cell-count, ink type and substrate used. Furthermore, impression pressure and nip distances are adjustable by increments of microns. As a result, the proofer is capable of offering full predictability of the target result, to within a fraction of ΔE, at the desired dot-gain.

With the Perfect Proofer, the operator has assurance of achieving color perfection without the need for re-adjustments on the press. This reportedly saves up to 15 minutes of set-up time per color.

The unit’s proofing head is available with either a 1in (25mm) or 2in (50mm) anilox roll and handles photopolymer plates. As the unit’s ink roller, anilox roll and impression roll are all gear-driven, it is possible to proof any substrate, including paper, film and carton board. The system is also compatible with all ink types. An accompanying fully automatic proof-head cleaning system, ‘Clean Machine’, removes ink residue from the head within a minute.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.