Polymount moves into gravure with launch of film cleaning machine

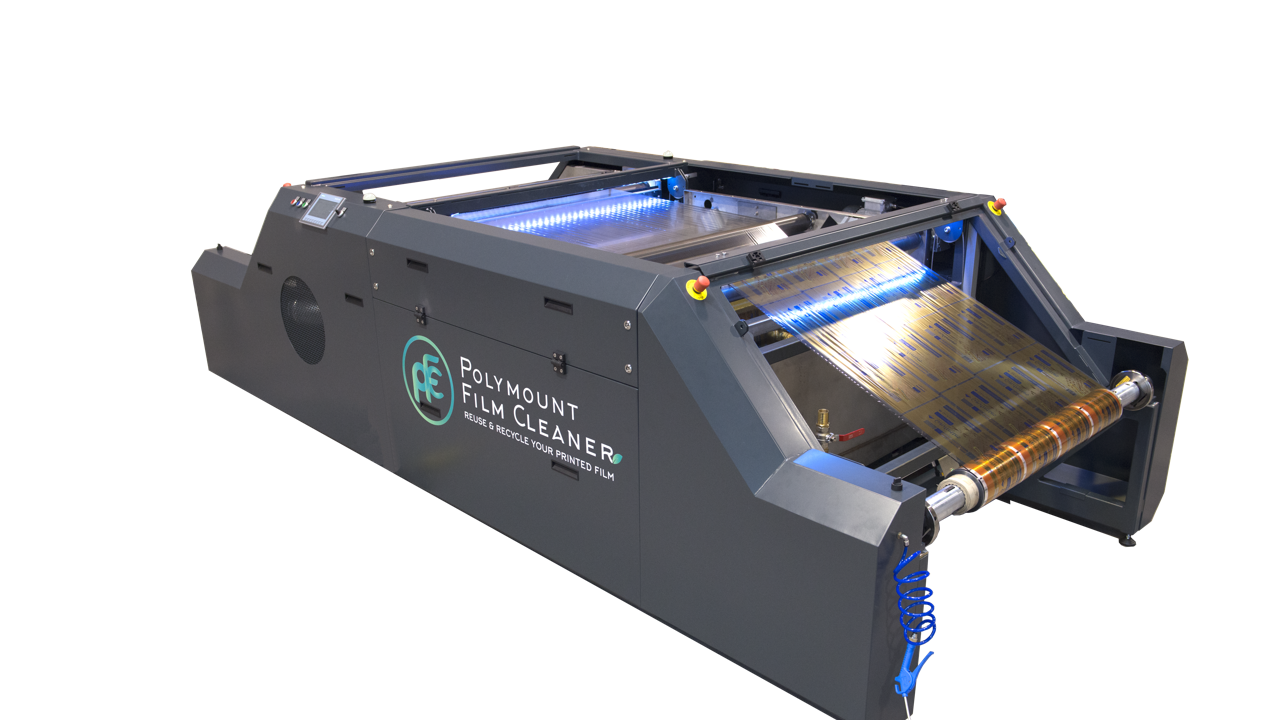

Polymount used drupa 2016 to debut its new film cleaning machine that removes ink from film materials and enables it to be used again during the next press start-up operation, 'significantly' reducing the waste generated by any printer, including those running gravure presses.

The machine sees the roll of printed film guided via multiple loops through a tank filled with a specially developed Polywash cleaning liquid. There is a recycle unit installed to keep the Polywash clean and maintain its de-inking ability. The last station sees the cleaned film dried using patented technology. The end result is a roll of clean and dry film which is ready for the next press set-up.

The Polymount Film Cleaner is able to clean different types of film, and to remove all types of water- and solvent-based inks. It is available in 1300mm and 1950mm widths, and cleans at up to 50m/min.

And while its Twinlock Sleeve and Plate Cleaner machines were both conceived for the flexo industry, the new Polymount Film Cleaner is also suitable for gravure printers. This opens up a whole new market for Polymount, and the company said the machine was a ‘big hit’ with both flexo and gravure printers at drupa 2016.

Read further reaction from labels and package printing suppliers to their presence at drupa 2016 here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.