Pulse Roll Label launches dual cure UV LED ink

Dual cure formulation from Pulse tackles rising energy costs

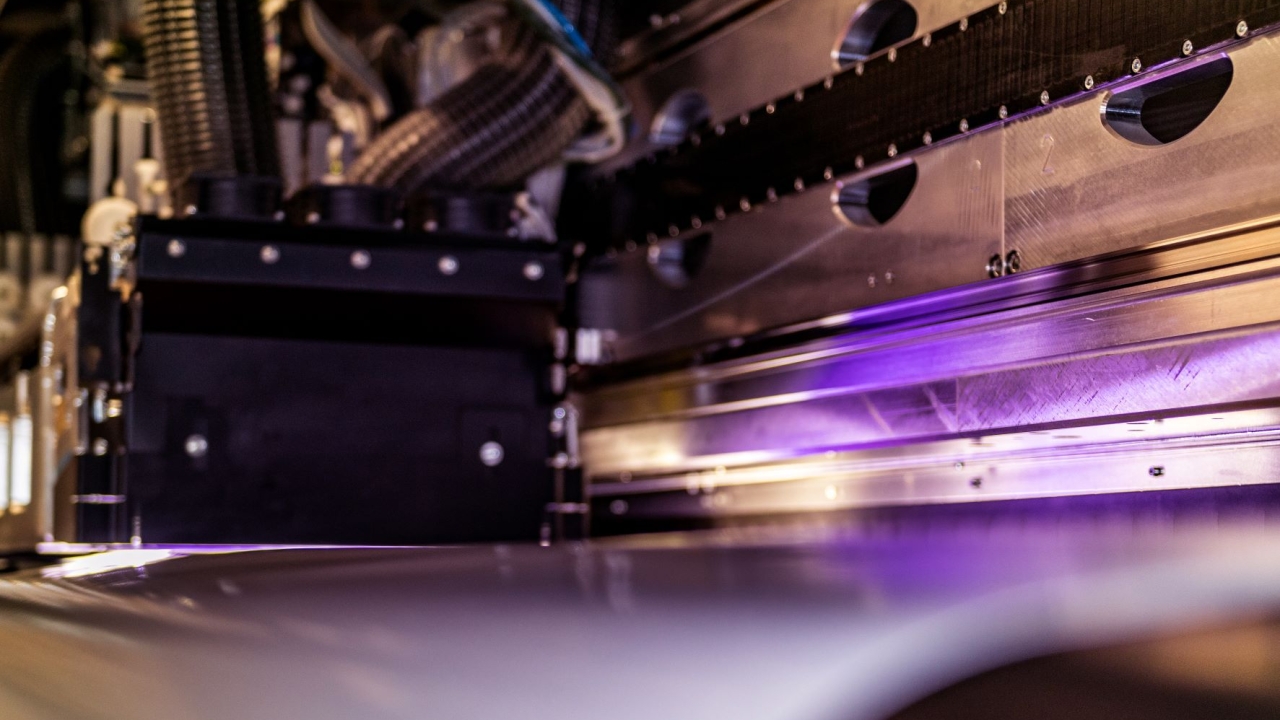

New ink can be cured with UV LED lamps

UK headquartered narrow web printing ink specialist, Pulse Roll Label Products is helping printers combat the cost of rising energy bills with the launch of its new dual cure UV LED ink range, PureTone DC.

The new high-performance ink can be cured with UV LED lamps, meaning the curing process uses just a fraction of the power of traditional UV lamps. Being fully food packaging compliant, the new ink is suitable for use within food packaging regulated sectors and the range also includes CMYK+OGV for extended color gamut printing.

LED lamps used with PureTone DC not only deliver a more stable light ensuring consistency of curing and print, but they can also be switched on and off instantly – unlike traditional UV lights, which must be left running – and they also last many times longer.

Crucially, PureTone DC’s dual cure formulation means printers can use just one set of inks with both UV and LED curing presses, further improving efficiency by avoiding unnecessary and costly inventory and ink management complexity, as well as being able to convert across press by press. The new ink also matches the strength of others in the Pulse range, making it easy to compare and match colours as necessary.

Gary Seward, managing director of Pulse Roll Label Products said: ‘LED curing is looking like the future of the industry. Offering increased performance compared with other suppliers, and with a dual cure formulation, this new solution gives printers the versatility and freedom they need to switch to LED ink at their own convenience.

‘At a time when our customers’ energy bills are soaring, solutions like PureTone DC that help cut costs with rapid, energy-efficient curing can make all the difference. As well as needing less energy to run, the UV LED lamps that cure this ink last much longer than traditional UV equivalents, with output remaining consistent over the bulb’s lifespan. What’s more, disposal is also significantly less complex with UV LED bulbs,’ Seward explained.

‘We’ve even seen improved cure and adhesion over the existing ranges during extensive beta testing, so this really is the next generation of PureTone ink,’ added Seward. ‘The message is clear – UV LED technology like PureTone DC is better for your business, your staff, your customers and the planet.’

Unlike some LED inks, PureTone DC’s dual cure formulation means the initiators within the ink are activated when exposed to either traditional UV lamps or UV LED light. This feature is designed to help printers gradually phase out their existing mercury-based curing equipment without the need for expensive initial investments. As an LED curing ink, PureTone DC can also cure at lower temperatures, making it suitable for a wider range of substrates including heat-sensitive thin films.

With the United Nations (UN) having committed to phasing down mercury use in a wide range of products and processes due to the substance’s harmful environmental and health effects, the ease of disposal of UV LED lamps is also another benefit to printers.

‘There are already significant restrictions in place on disposal of mercury and introducing it into the waste stream, and these regulations are only tightening,' Seward explained. ‘With different rules and procedures across different countries around the world – particularly with regard to landfill – printing businesses are looking to transition away now, to get ahead of the changes on the horizon.

‘The ongoing uncertainty over the future of mercury regulations in flexo printing, coupled with the enormous cost and energy benefits, means there’s never been a better time to make the change to UV LED ink,’ Seward added.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.