RK Print upgrades K 303S Multicoater

RK Print Coat Instruments has modified the K 303S Multicoater base unit with a fully integrated servo drive and touch screen control to offer a new level of precision for most coating and adhesive-related applications.

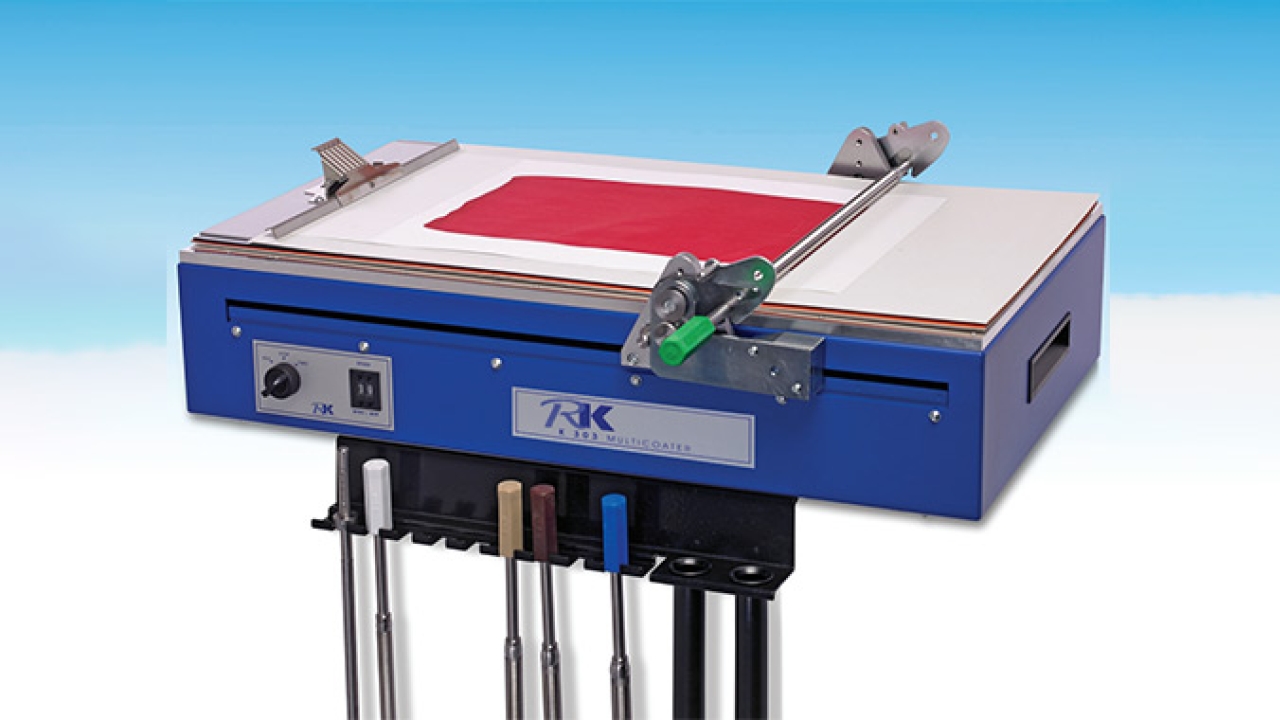

The K 303S benchtop unit has some similarities with the earlier version of the K 303 Multicoater. It is supplied with easily interchangeable gravure and flexographic printing heads and offers meter bar coating capability.

The machine offers variable speeds, ranging from 1 to 40m/min. Multiple coatings may be performed simultaneously with the K 303S for comparison purposes with the maximum coating area measuring 350 x 440mm. Vacuum beds are also available.

The K 303S can be used for quality control and color comparison using various ink/substrate combinations and to determine printability and adhesion. The meter bar coating head expands processing and quality control capabilities. Bars are available for wet coatings from 4 to 500 microns. The samples obtained are suitable for computer color matching, visual color matching and the evaluation of adhesion, gloss and other quality/performance associated parameters.

The servo-driven motor offers smooth operation at any speed controlled using an HMI with a 2-button mode switch for safety. Servo motors are available in an extensive range of sizes, shapes and types.

‘Regardless of the many issues that arise, the printer and converter must meet the quality expectations of the customers who demand a high degree of accuracy with regard to color, text, graphics or other process objective,’ commented Tom Kerchiss, managing director of RK Print Coat Instruments. ‘For laboratories, research establishments and printers and converters with multiple print process facilities, the K 303S may be the solution.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.