rosas Maschinenbau launches four new products

rosas Maschinenbau, a German manufacturer of tabletop rewinder and inspection machines, has introduced four new products for the label converting market: the Infinity 4K line scan camera, its second-generation Gazelle high-speed bidirectional rewinder, the FP III flexo printing unit series, and the Deer I smart and compact web doctor machine.

The Infinity 4K line scan camera is designed for tabletop rewinders that handle web widths of up to 520mm. It features new AI-based print inspection technology providing label checking capability similar to that of a human operator with decades of experience.

The system works with automatic setup software and capabilities such as PDF master check and rollmap with PDF proof report. It can inspect various labels, including pharma, wine, natural material such as wood, and labels with random or holographic backgrounds and reflective surface material such as gold embossing.

The system works with automatic setup software and capabilities such as PDF master check and rollmap with PDF proof report. It can inspect various labels, including pharma, wine, natural material such as wood, and labels with random or holographic backgrounds and reflective surface material such as gold embossing.

Code reading and logging are also part of the system, complete with reflex-free illumination, screen, and CFK encoder roller. Designed for rosas’ Cheetah 500 and Leopard tabletop rewinders, the Infinity 4K line scan camera can also be installed in other industry label converting and printing machines.

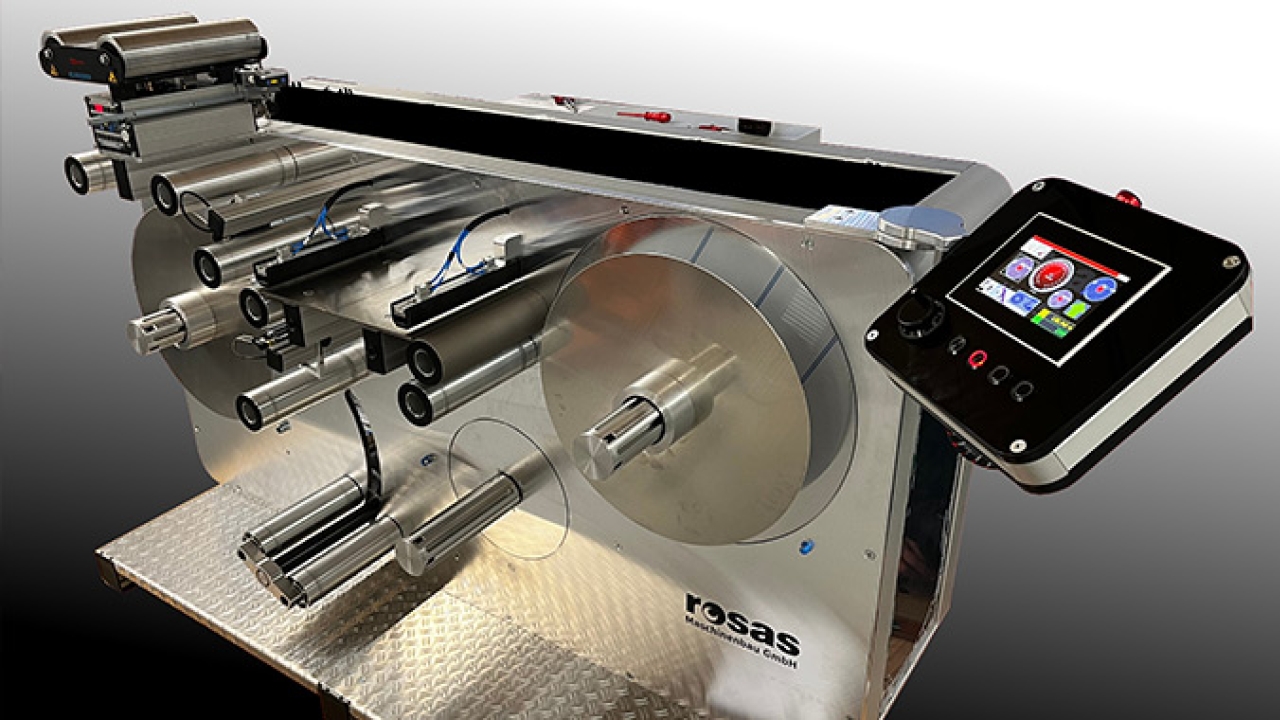

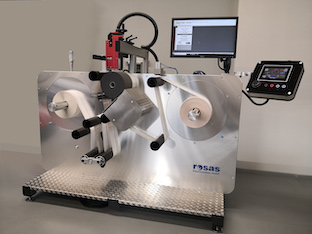

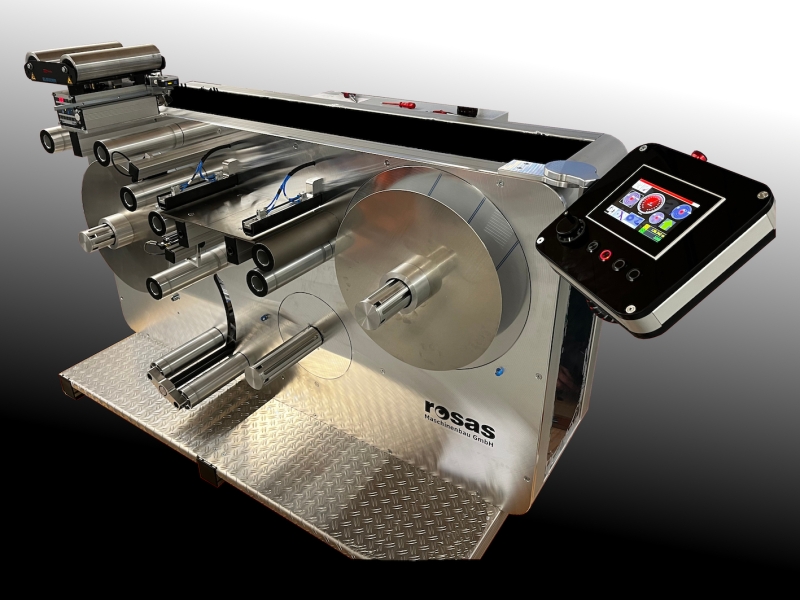

Rosas has introduced the second-generation Gazelle high-speed bidirectional rewinder for imprinting a variety of label types. The company collaborated on the development with Graph-Tech USA, which incorporated its EZ 202 DOD color inkjet head based on Epson S3200 technology.

This inkjet head and complementary UV LED curing system enables the machine to deliver real-time database serialization at 1200 DPI in full color at production rates of up to 50m/min.

This inkjet head and complementary UV LED curing system enables the machine to deliver real-time database serialization at 1200 DPI in full color at production rates of up to 50m/min.

The Gazelle II DOD Color is also designed with a pre-installed interface for the fully automatic 100 percent inspection module, quick release of tension axles (for simple reel change installations and removals), and web tension on the curve (hard on the inside and soft on the outside).

The new FP III flexo printing unit series is available in web widths from 330 to 1,100mm and works with gravure cylinder sleeve technology. Every cylinder features a gearless servo drive that enables a simple, format-free change from the doctor blade chamber to the pressure rubber cylinder.

In addition to rosas Turbo FF, the FP III flexo printing unit has been integrated with the Gallus RCS, Spec in-line finishing machine, B Bunch fan-folding machine, Müller Martini Progress, and the Giebeler R520 press.

In addition to rosas Turbo FF, the FP III flexo printing unit has been integrated with the Gallus RCS, Spec in-line finishing machine, B Bunch fan-folding machine, Müller Martini Progress, and the Giebeler R520 press.

Rosas’ fourth new product is the Deer I smart and compact web doctor machine. With the ability to run at a maximum production speed of 400m/min (with the possibility of 600m/min), it features a third waste rewinder for removing longer misprints and converting errors and a splice table with integrated pneumatic clamps.

Other features of the Deer I include a web width of 330 to 1200 mm, format range up to 30in, cliché or anilox cylinders as sleeves with gearless servo drive providing fast and easy changeovers, and a doctor blade chamber or scoop roller section.

Other features of the Deer I include a web width of 330 to 1200 mm, format range up to 30in, cliché or anilox cylinders as sleeves with gearless servo drive providing fast and easy changeovers, and a doctor blade chamber or scoop roller section.

Two of rosas’ new products featured at Labelexpo Americas on its stand 6515 are the Infinity 4K line scan camera and the second-generation Gazelle high-speed bidirectional rewinder.

The Infinity 4K camera will be demonstrated on rosas’ Cheetah 500 tabletop rewinder with backside serialization and a TIJ printer for numbering and coding. The second-generation Gazelle rewinder will be shown with the Graph-Tech USA EZ 202 DOD color inkjet head. Graph-Tech is rosas’ local agent in the USA for the Gazelle rewinders.

‘These four new products reflect rosas’ specialty in manufacturing a variety of customized machines and units with the latest technology and partnering with other industry specialists in label converting,’ said David Rosas Wolf, managing partner of rosas Maschinenbau. ‘We look forward to demonstrating two of these new product developments at Labelexpo Americas in Chicago.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.