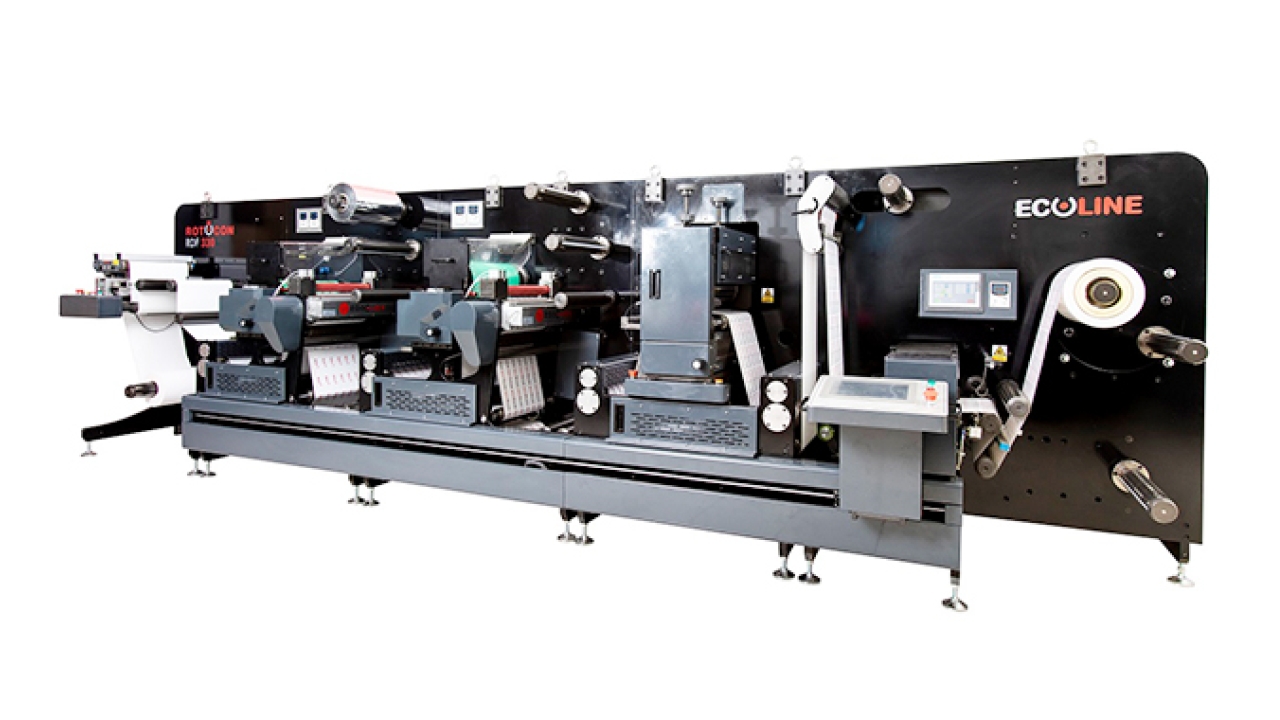

Rotocon releases next generation Ecoline RDF 330

Rotocon has released the next generation Ecoline RDF 330 digital printed label converting and finishing machine with several upgrades including automatic sheer knife slitting and high-speed matrix stripping.

A first major upgrade of the RDF 330 is an automatic sheer knife slitting system that simplifies the set-up and tweaking required when manually adjusting blades across more than three lanes. The operator can now enter the label sizes, gap sizes, and number of slits then the system will automatically bring all the blades into the right position with the correct gaps.

Rotocon has added a high-speed matrix stripping system, which ensures no web in between the stripping shaft and matrix, preventing waste breakage and machine downtime. Additionally, a servo-driven motor enables appropriate stripping tension, even in the presence of matrix coil diameter variations. This avoids any issues caused by special substrates or die-cutting complex label shapes.

The company has also introduced a dual-turret slitter rewinder with two spindles enabling finishing a roll of labels directly on the RDF 330 in one pass.

Inclusion of the easy-to-operate Ecoline branded UV LED curing system is a fourth important upgrade, which facilitates significantly lower operating costs thanks to energy savings, less consumable parts, and lower maintenance costs.

Finally, the next generation Ecoline RDF 330 uses the latest servo motor and software enhancements available.

‘The Ecoline RDF, initially introduced into South Africa back in 2013, has evolved into a globally supported brand with installations across Australia, Europe, and North America through Rotocon Europe and Rotocontrol,’ commented Michael Aengenvoort, CEO of Rotocon. ‘By establishing close partnerships with our customers, we could incorporate their valuable upgrade recommendations to enhance the machine performance for offline label embellishments and finishing.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.