MM Packaging urges plastic reduction in pharma

The company highlights a valuable opportunity for the pharma sector to lead the way in plastic reduction.

MM Packaging, secondary packaging specialist to the pharmaceutical sector, has called on the industry supply chain to accelerate efforts to reduce its reliance on plastic packaging.

As the pharma industry faces increasing pressure to reduce its environmental impact, MM Packaging highlights a valuable opportunity for the pharma sector to lead the way in plastic reduction and enhanced material circularity.

Laura López Pajarón, marketing manager at MM Packaging Pharma and Healthcare, said: ‘The pharma industry has not typically been under pressure on sustainability to the same extent as more consumer-facing retail categories, but this is changing. Many new regulations, such as Extended Producer Responsibility (EPR), center around reducing the volume of waste from packaging, and we are ready to be a voice for change. One of the most effective ways to reduce waste is by focusing on recyclability and the circular economy.

‘A prominent advantage of switching from plastic to cartonboard is that it’s very easy to recycle in existing infrastructure, so it’s a solution for right here, right now. We urge our partners in the pharma supply chain to join us in this critical journey towards a stronger circular economy.’

MM Packaging primarily uses renewable resources and materials to create fully recyclable pharmaceutical packaging. The business has ongoing sustainability reporting partnerships with Ecovadis, Ecodesk, SEDEX, and CDP (Carbon Disclosure Project).

Across its global production facilities, which includes 28 sites dedicated to the pharma industry, MM Packaging operates core sustainability initiatives designed to reduce its impact on the natural environment. These include Zero Waste to Landfill programs, multi-level energy reduction projects, and a connected carbon footprint reduction drive.

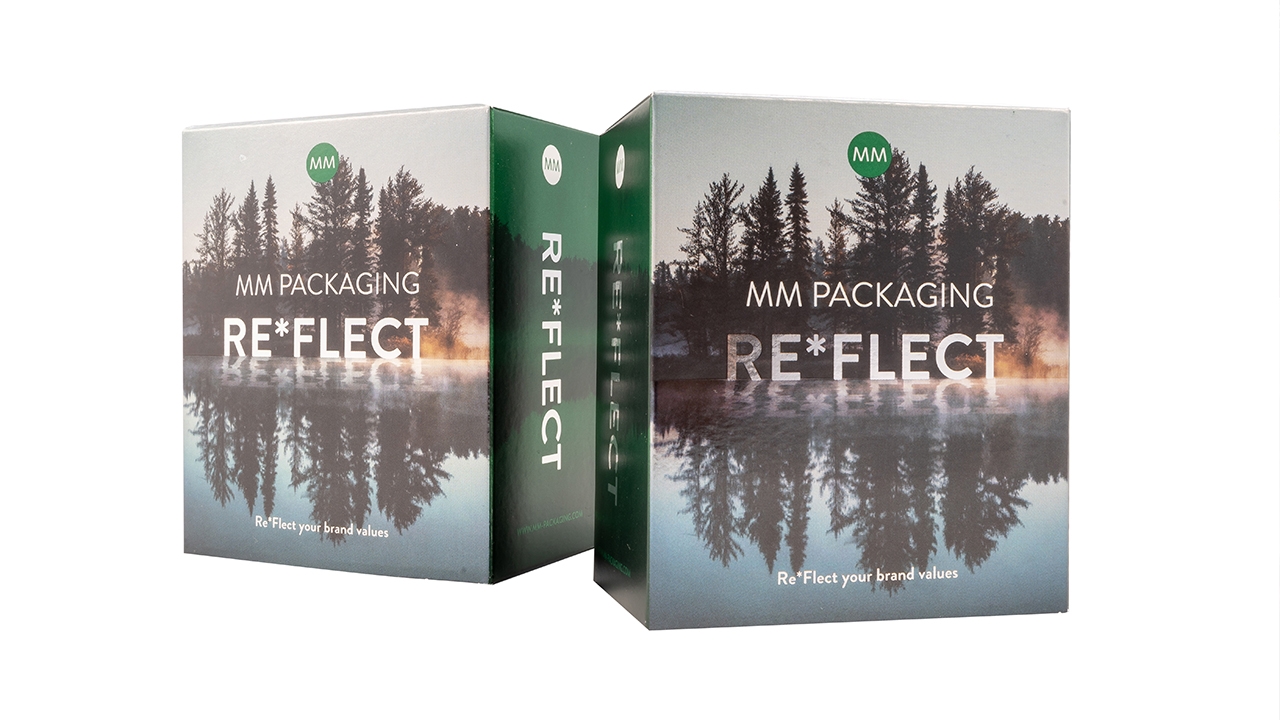

‘At MM Packaging, we don’t see sustainability as just a responsibility or obligation for the pharma category, but an enormous opportunity,’ said López Pajarón. ‘A great example of how plastic reduction can be made simple through innovation is Re*flect, our plastic-free alternative to MetPol (Metallised Polyester). The solution retains the visual impact of traditional MetPol without the need to adapt packaging artwork but is completely recyclable.

‘Plastic-free Re*flect is a great example of how packaging technology is pushing pharma sector sustainability harder than ever before, and we’re at an important industry tipping point. Plastic reduction is core to the industry’s evolution, and we look forward to seeing how businesses rise to the challenge. Our team will, of course, be standing by to support our pharmaceutical customers in closing the packaging loop.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.