How to improve print quality in four steps

1. Select the right line count

The screen specification of an anilox roll is an important consideration which will impact print quality. The objective is to use always the finest anilox screen count possible, providing we can achieve the required color densities.

Higher line counts will provide a finer ink distribution, which will be critical during the printing process. The line count determines the total number of ink dots that will be transferred to the plate. Higher line counts place more cells closer together. Smaller dots will dry faster, producing less dot gain, which will offer better image clarity in process jobs.

When selecting a line count for a process job, the rule of thumb is to specify the line count at least five times the plate screen. This ratio allows the cell walls to adequately support the dot and keeps the dot from dipping into the cells.

Line count is chosen in correlation with cell volume. For example, if for printing solids a volume of 8 cm3/m2 is required, the line count will be approximately 400 LPI. Please consult Cheshire Anilox Technology’s volume chart to select the optimum volume for the chosen line count.

The only downside with fine line counts is the cell size is reduced, becoming more challenging to deliver an adequate cell volume for achieving the correct color densities.

2. Maintain a consistent volume

Maintaining a consistent ink volume is critical to color reproduction, and the anilox engraving specifications are key to controlling ink film thickness on the printing plate.

Ink film thickness is the volume of ink that transfers to the printing plates and is what determines color strength and print quality. The strongest, thinnest film of ink (while maintaining color density) always prints best. Without enough volume, the color prints weakly. On the other hand, an overload of ink results in dirty print or too much dot gain.

In order to find that sweet spot in the amount of ink transferred to the substrate, a number of things must be addressed, like the type and viscosity of the ink, the type of printing plates used, and the types of substrates. However, in order to systematically control the color and print quality, the consistency of the engraving is paramount.

One main factor that will affect the ink transfer from the anilox cells is the cell shape and engraving geometry. In order to ensure a consistent ink film thickness, the anilox specification should be within a depth-to-opening ratio of approximately 30 percent. This will ensure a good, effective ink release from the anilox cells to the plate.

Depth-to-opening ratio is defined by how shallow or deep the cells on an anilox roll are. For example, if a cell is 30-µ. deep and 100-µ. wide, its depth-to-opening ratio is 30 percent. On average, a 30 percent depthto-opening ratio may transfer 20 percent of this volume to the web. If the same cell is 40-µ. deep, its depth-to-opening ratio is 40 percent. This cell may transfer 18 percent of what it holds to the web.

In other words, at a given line count, the deeper a cell gets, the percentage of ink transferred to the plate reduces. When possible, it is recommended to use depthto-opening ratios in the 30 percent to 35 percent range.

3. Cell geometry

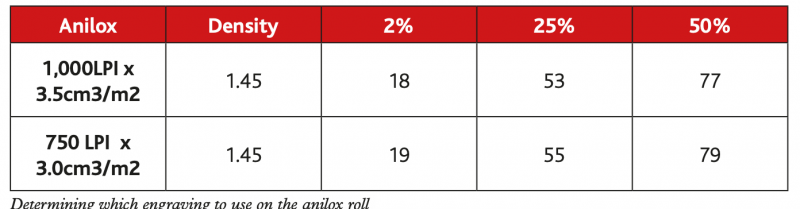

How does one determine which engraving to use on the anilox roll? As shown in the chart, it is not solely the volume of the anilox roll. Rather, it is a function of the cell geometry on the anilox roll that dictates exactly how much ink transfers to the printing plate. This ink film thickness should be the focus when selecting an engraving. The chart is an example in which the same ink film thickness was achieved using two different volumes. The result? Both the color strength and dot gain were almost identical.

How can a 3.5 volume produce almost identical results when compared to a 3.0 volume? The 1,000 is a deeper engraving and releases less of what it holds. This results in the same ink film thickness to the printing plate as the 750 with a lesser volume because the shallower cell releases more of what it holds. Essentially, the shallower cell has a more efficient ink transfer.

How can a 3.5 volume produce almost identical results when compared to a 3.0 volume? The 1,000 is a deeper engraving and releases less of what it holds. This results in the same ink film thickness to the printing plate as the 750 with a lesser volume because the shallower cell releases more of what it holds. Essentially, the shallower cell has a more efficient ink transfer.

If a printer is using consistent depth-toopening ratios for all volume requirements, the same percentage of ink will transfer to the plate. This will make it easier to identify which rolls to use with new colors and print jobs.

On the other hand, using inconsistent or excessive depth-to-opening ratios will result in more adverse side effects than just color matching issues. Deep engravings are rough, form inconsistent cell walls and introduce many variables that greatly reduce the chance of consistency in your printing process.

Choosing line counts at proper depthto-opening ratios ensures uniform cell geometries. The cell walls form more consistently and produce engravings that will last longer, print more consistently and be more resistant to damage. Furthermore, if cleaning anilox rolls is a challenge, keeping the depth-to-opening ratio at less than 40 percent will make rolls easier to maintain.

New laser engraving technology has allowed the development of new engravings that offer a greater ink transfer and consistency of ink volume at the same or higher line counts. The reason for this is engraving cells or patterns with a better and more effective shape that is more efficient at ink release.

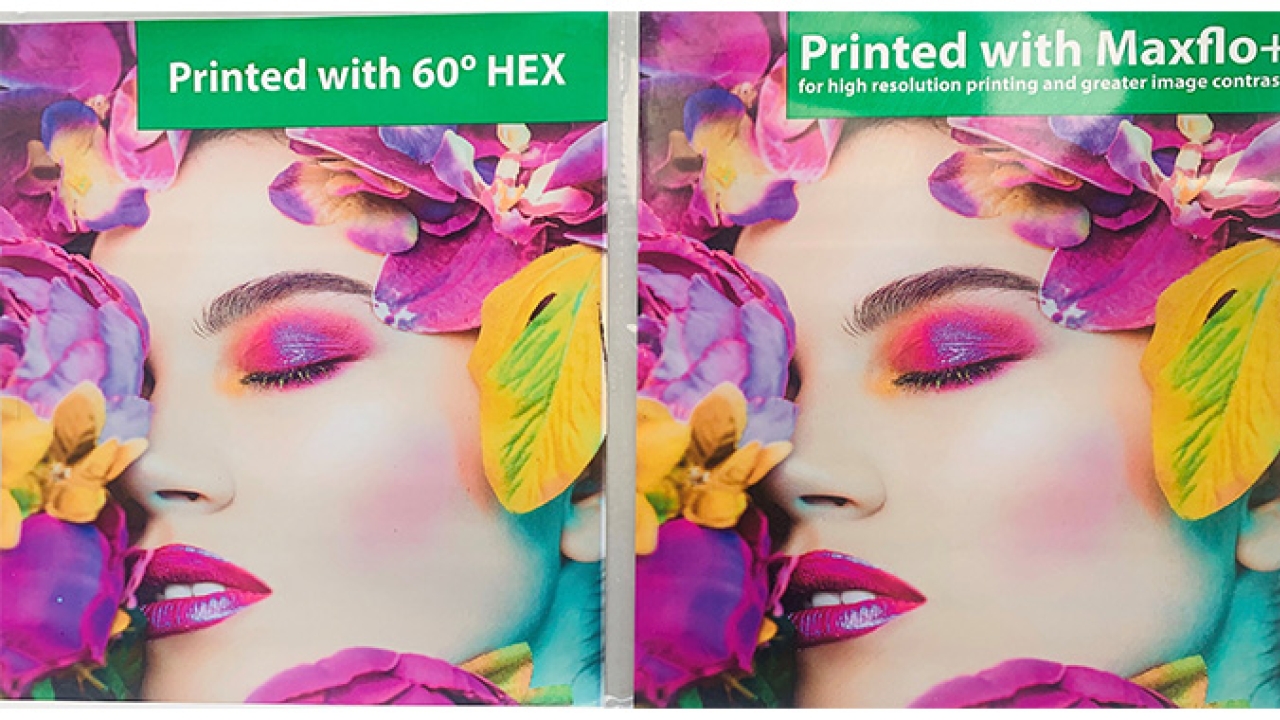

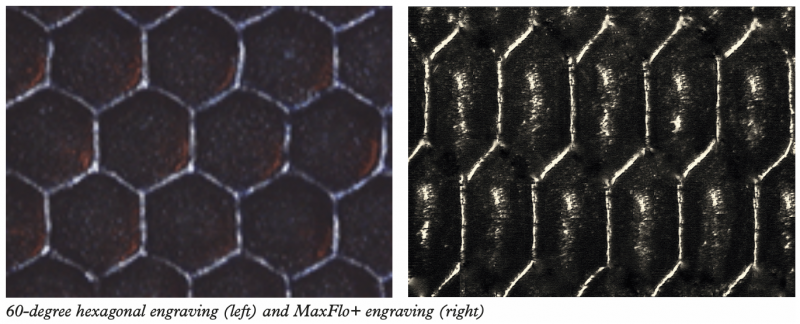

The images below show engravings at the same volume and depth-to-opening ratios. To the left is a standard 60-degree hexagonal cell. If dots on the print are smaller than the opening of this cell, new cell geometries (like MaxFlo+ on the right) can increase the plate support by increasing the horizontal linescreen count by about 40 percent. However, to maintain a proper depth-to-opening ratio, the vertical line count has been reduced. About the same number of cells exist on the roll, but the final result is sufficient plate support for smaller dots.

4. Adequate maintenance

The key to ensuring maximum performance from anilox rolls is implementing a preventative maintenance program. This means not only ensuring rolls are thoroughly cleaned after each use, but also tracking their essential data points.

Anilox cleanliness is critical because dirty or clogged cells can degrade performance by reducing cell volume and causing uneven appearance or random patterns in the print or coating.

In order to ensure reproducible results, regular cleaning is essential. Adequate cleaning and maintenance will preserve the original characteristics of your Anilox rollers and prolong their life.

It is imperative that when an anilox roll is returned to storage that any chips or scoring lines have been documented. The volume should be measured, and the data should be captured so the prepress department knows that each roll is 100 percent ready to run the next job.

By taking the proper precautionary measures and maintaining a strict cleaning regimen, converters are likely to see vast improvements in how long their anilox rolls remain viable.

Go to www.cheshireanilox.co.uk for more information

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.