Q&A with CELAB representatives

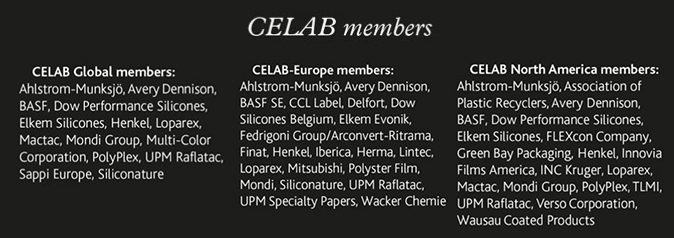

L&L: What is CELAB and who can be a part of it? Anzelma Hajro, marketing programs and compliance manager at Avery Dennison Label and Packaging Materials, CELAB-Europe Steering Group chairperson: CELAB stands for Circular Economy for Labels. The full name including tagline is CELAB, Towards a Circular Economy for Labels. This is the first global consortium dedicated to recycling in the self-adhesive labeling industry. Under the global CELAB umbrella, regional consortia are currently being set up. CELAB-Europe now has 20 members, mostly release liner and chemical producers as well as self-adhesive label materials producers.

Anzelma Hajro, marketing programs and compliance manager at Avery Dennison Label and Packaging Materials, CELAB-Europe Steering Group chairperson: CELAB stands for Circular Economy for Labels. The full name including tagline is CELAB, Towards a Circular Economy for Labels. This is the first global consortium dedicated to recycling in the self-adhesive labeling industry. Under the global CELAB umbrella, regional consortia are currently being set up. CELAB-Europe now has 20 members, mostly release liner and chemical producers as well as self-adhesive label materials producers.

Francesc Egea, director at IPE Industria Gráfica and former Finat vice president, representing Finat on the CELAB-Europe Steering Group: Finat has been representing the interest of label converters in the initial stage and is currently also hosting the European consortium. Our goal is to have label converters, label users and other parties from the value chain like recyclers and logistic providers join this collaborative initiative as well.

Francesc Egea, director at IPE Industria Gráfica and former Finat vice president, representing Finat on the CELAB-Europe Steering Group: Finat has been representing the interest of label converters in the initial stage and is currently also hosting the European consortium. Our goal is to have label converters, label users and other parties from the value chain like recyclers and logistic providers join this collaborative initiative as well.

L&L: What are CELAB’s priorities? Ralf Drache, director of sales and marketing at Herma, CELAB-Europe Steering Group member: CELAB’s vision is to create a sustainable self-adhesive labeling industry by offering solutions and providing education to enable matrix and release liner recycling. CELAB’s mission is that the self-adhesive labeling industry has access to matrix and release liner recycling. Comprising many of the self-adhesive label industry’s largest companies, CELAB will operate as a technology and solution neutral coalition, empowered to reach across the entire value chain to promote a circular economy for self-adhesive label materials.

Ralf Drache, director of sales and marketing at Herma, CELAB-Europe Steering Group member: CELAB’s vision is to create a sustainable self-adhesive labeling industry by offering solutions and providing education to enable matrix and release liner recycling. CELAB’s mission is that the self-adhesive labeling industry has access to matrix and release liner recycling. Comprising many of the self-adhesive label industry’s largest companies, CELAB will operate as a technology and solution neutral coalition, empowered to reach across the entire value chain to promote a circular economy for self-adhesive label materials.

CELAB is designed to facilitate collaboration at a global level and encourage the universal adoption of best practices while fostering regionally appropriate initiatives and cooperation. Brands are eager to communicate their commitment to sustainability in response to consumer demands. With increased recycling capability gradually emerging from suppliers, producers, waste management, chemical recyclers and others, we see a tremendous opportunity to facilitate collaboration with partners up and down our industry’s value chain.

L&L: What is the role of the global and regional branches?

Anzelma Hajro: The Global Steering Committee sets priorities for the consortium, coordinates the communication and information flow between the regional branches to share and spread best practices, and facilitates market and technical research that supersedes the regional level. For instance, CELAB recently commissioned AWA to conduct a global market research study. The study reports on the current state of volumes, recycling rates and recycling capabilities that can be adopted around the world, and includes a quantitative assessment of the worldwide market, by key geographic regions for paper liner and PET release liner, that provides insights into the current end-of-life reality.

Furthermore, under the leadership of Alex Knott (Dow Chemical Company), CELAB is currently conducting a technical review of release liner recycling to understand existing recycling technology by gathering information on current processes. Here, CELAB is preparing a series of white papers that will include input from raw materials producers (paper and silicone), recycled paper producers, recycling companies (collection) and industry organizations to understand the impact of release liner not only on the final recycled paper product but also on the paper making process. The objectives of these white papers are to provide basic technical information on liner recycling on a global basis, without sharing proprietary process information. The first of this series of documents, on paper liner recycling, has already been completed and is in the process of being shared with the wider self-adhesive label industry.

In turn, the regional branches create workstreams on various aspects of matrix and release liner recycling, including analyzing technical issues, promoting the use and creation of recycling networks and solutions, interacting with government regulators, and educating the industry and public.

L&L: What has CELAB-Europe achieved since February 2020?

Anzelma Hajro: Within CELAB-Europe we agreed on a vision, target and strategic objectives. CELAB’s vision is to create a self-adhesive labeling industry which is increasingly circular by offering solutions and providing education to enable matrix and release liner recycling. CELAB-Europe’s goal is for over 75 percent of the used release liner and matrix material to follow a circular business model by 2025. We aim to contribute to the development of cost-effective environmentally friendly solutions for pre-consumer waste. In doing so, we are establishing a representative self-adhesive label value chain organization to drive progress in meeting legislative and customer requirements. This way, we are utilizing the value chain to understand, build scale and collectively advance recycling solutions for matrix and liner.

In Europe, we have organized ourselves in four working groups (workstreams) with an overarching Steering Group. The original target was to kick off the project on the occasion of the Finat Technical Seminar back in March, but due to the pandemic, all workstream meetings so far have taken place online. In hindsight, this situation has enabled us to make big strides forward in defining the deliverables in each of the workstreams, and make progress in areas like market data collection, the identification and assessment of existing and potential recycling and logistics solutions around Europe, as well as the assessment of the regulatory framework around Europe relevant to the implementation of pan European solutions. All our activities are based on a governance agreement which identifies the terms of engagement for the members as well as the legal compliance with competition law.

L&L: What is required logistically to improve current recycling rates?  Juha Virmavirta, UPM Raflatac and Logistics Workstream leader, CELAB-Europe Steering Group member: There are a range of factors that CELAB has identified to improve recycling rates, ranging from education of the industry regarding the availability of nearby solutions, to raising awareness among brand owners and converters.

Juha Virmavirta, UPM Raflatac and Logistics Workstream leader, CELAB-Europe Steering Group member: There are a range of factors that CELAB has identified to improve recycling rates, ranging from education of the industry regarding the availability of nearby solutions, to raising awareness among brand owners and converters.

CELAB-Europe will play a role in guiding the industry by, for example, identifying the hot spots where waste is being generated. The collection and waste operators need then to take the role of actively developing the concrete solutions. CELAB-Europe will investigate new ways to transport waste, waking the interest of the established players in the waste markets, finding new agile operators and using digitalization. Of course, all solutions must be economically viable, or they won’t be sustainable.

L&L: How is CELAB going to support the development of a sustainable business model for recycling?

Juha Virmavirta: This is a work in progress. Via the CELAB-Europe Workstreams, different business models will be explored to understand the economics and environmental impacts of each potential recycling /reuse scenario. This understanding will be shared within CELAB so that the most relevant can be developed into fully fledged commercial solutions. Throughout this process CELAB will be careful to ensure compliance with competition law.

L&L: What is the scale of the problem? How is liner and matrix waste currently disposed of?

Ralf Drache: While it is clear that our initial focus has been on liners, we should not forget about matrix. Within Europe, we are currently also collecting data about the amount of matrix materials generated by the label value chain. We will work with Finat in addressing the label printing community on this topic.

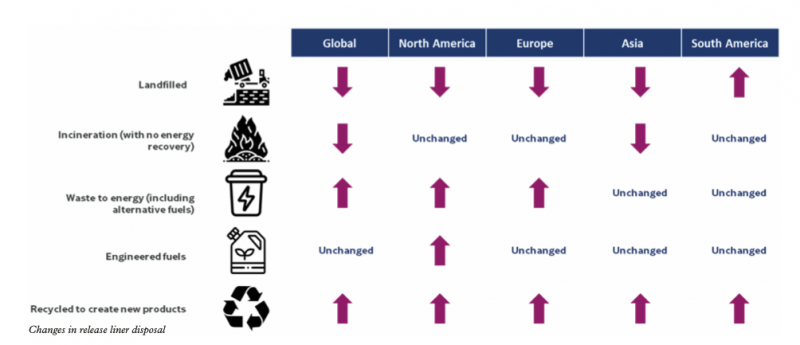

According to study last year commissioned by Avery Dennison for CELAB and conducted by AWA, there are 1.6 million tons of label liners sold worldwide, with a recycling rate into other material of approximately 20 percent. The numbers vary by region. In Europe, landfill in several countries has already been or will soon be banned, and compared to energy the focus here lies on the creation of secondary raw materials. For paper liners, over 50 percent is being recycled to create new products, while 25 percent is converted from waste to energy. For filmic liners, almost half of the volume (49 percent) is being converted from waste to energy, and one quarter is recycled to new products. The challenge is not only to increase the share and availability of recycling solutions, but to also help to upgrade the quality of recycling and demand for recycled solutions.

L&L: What is currently the biggest difficulty with release liner recycling?  Fernando Giron, marketing director for Pressure-Sensitive Labels Business Unit at Fedrigoni Group, Arconvert-Ritrama, and CELAB-Europe Steering Group member: The main challenge is to make the recycling economically viable, which is difficult to achieve due to a combination of two factors. Firstly, technical complexity: the liner’s silicone coating and the high density of paper (for paper liner) require specific processing. The specific nature of the liner could also lead to lower yield or lower grade recycled material. Secondly, transport cost: a large portion of recycling costs come from transport. The volumes of used liner are very fragmented and only a few specialized recycling plants are available in Europe, making the transport cost a real challenge.

Fernando Giron, marketing director for Pressure-Sensitive Labels Business Unit at Fedrigoni Group, Arconvert-Ritrama, and CELAB-Europe Steering Group member: The main challenge is to make the recycling economically viable, which is difficult to achieve due to a combination of two factors. Firstly, technical complexity: the liner’s silicone coating and the high density of paper (for paper liner) require specific processing. The specific nature of the liner could also lead to lower yield or lower grade recycled material. Secondly, transport cost: a large portion of recycling costs come from transport. The volumes of used liner are very fragmented and only a few specialized recycling plants are available in Europe, making the transport cost a real challenge.

Hence the need to find ways to increase the yield of the recycled liner material, and also the need for the whole value chain to collaborate to reach the scale needed to make this economically interesting and sustainable.

L&L: What are the markets for repurposed and recycled liner and matrix materials?

Fernando Giron: According to the release liner study done by AWA in 2019, current end markets include: recycled paper and cardboard, other materials such as cellulose fiber insulation material, and closed loop recycling into high quality papers. According to the same study, filmic liners are recycled into different composite materials but also new films.

The matrix is more difficult to recycle. Matrix waste is recycled to produce, for example, composite materials or blended into surface materials for roads.

CELAB will identify existing outlets make them more visible by label users, providing them with information on how to get the input material. In parallel, the workstreams will connect with companies specialized in matchmaking secondary materials to recycling solutions across industries, to expand the number of recycling or repurposing options.

Finat and CELAB-Europe

‘Finat is excited to host the European branch of this ground- breaking global initiative in its start-up phase,’ says Jules Lejeune, managing director of Finat. ‘For decades, our association has been active in raising awareness about the recycling of liner and matrix materials, and in promoting successful recycling solutions via our sustainability and recycling award.

‘Finat is excited to host the European branch of this ground- breaking global initiative in its start-up phase,’ says Jules Lejeune, managing director of Finat. ‘For decades, our association has been active in raising awareness about the recycling of liner and matrix materials, and in promoting successful recycling solutions via our sustainability and recycling award.

‘Finat brings together all the key players in self-adhesive labeling technology in Europe, from base materials up to the finished label and labeling technology, and I am proud and excited that our industry is now leveraging its resources collaboratively to take this important opportunity to the next level together with other stakeholders.

‘Only with a collective effort that is shared across the value chain can we make a difference and contribute our part to achieving a circular business model for the labels and packaging industry in Europe.’

For more information go to www.celabglobal.com

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.