London agency makes Manter shine

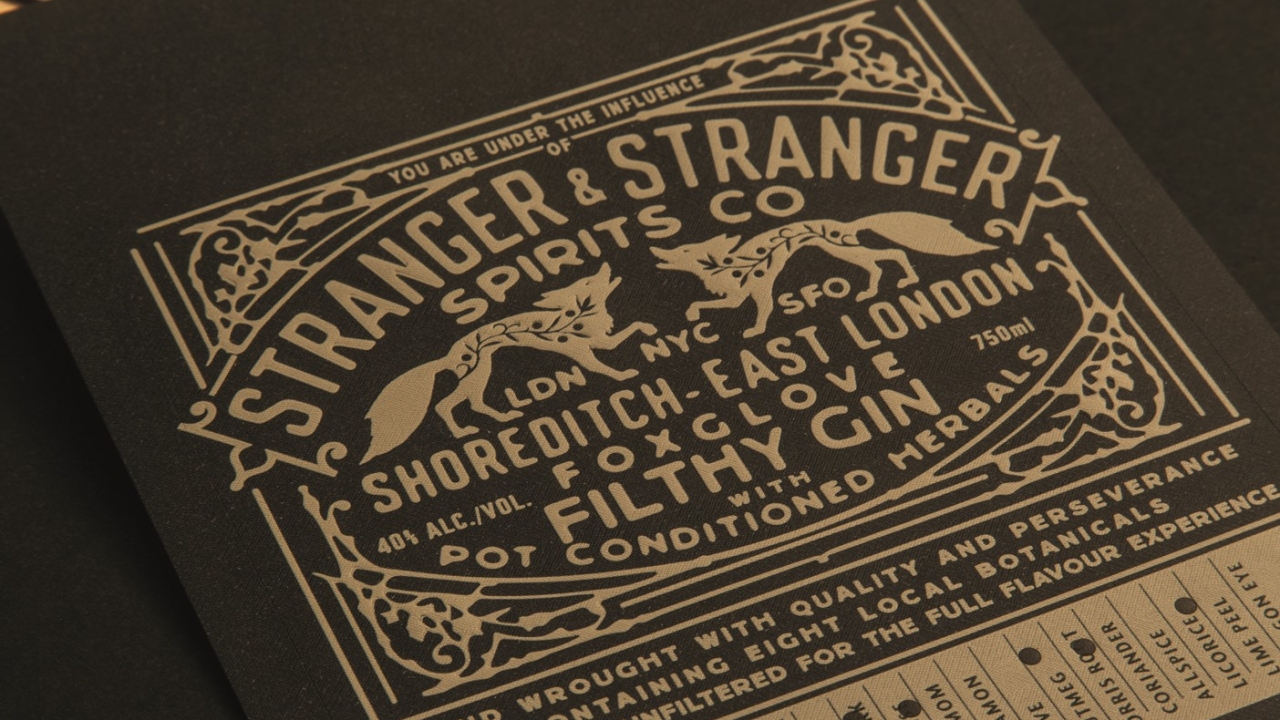

London-based global design agency Stranger & Stranger has produced a series of stunning labels showcasing Manter/Arconvert’s latest Spirits & Liquors Label Collection.

Each design – converted by a leading Spanish label printer – takes one high value self-adhesive face paper and applies a combination of print, decorating and converting processes to give inspiration to brands and designers involved in the premium wine and spirits sector.

‘We love using the Manter papers,’ says Ivan Bell, group managing director at Stranger & Stranger. ‘They allow us to create labels which really stand out in the premium wines and spirits sector where we specialize. The texture and finish of the label papers are a very important part of this, and they give us an edge when we present to clients and when the products are on the shelf.’

Bell points out that structured papers like the Manter Spirits & Liquors collection also provide a valuable anti-counterfeit function as the tactile feel can be hard to mimic.

For Mark Payton, designer and realization manager at Stranger & Stranger, the mechanical properties of the Manter papers are equally important: ‘The coatings take hot and cold foil stamping equally well. This is a big plus point, because it means that if we can’t make the price point for a hot stamp, we can resort to a cheaper cold foil and there will be very little difference in quality. Given the choice, of course, we prefer a hot foil because we can get very fine reversed type. On the other hand you can overprint cold foil more easily and you can achieve some very nice effects.’

Another important performance aspect of the Manter papers is resistance to absorption. ‘When printing screen, absorption characteristics are important,’ says Payton. ‘Flat screen in particular requires a high level of stability, and some cheaper papers will absorb the ink. This can be a big problem if you turn up for a press pass and it’s an unfamiliar paper which has been substituted.’

This points to a key lesson for print buyers – changing the paper specification at the last minute to save costs can end up costing money, as Payton relates: ‘Where a paper has been substituted which we haven’t signed off, we’ve needed to think on our feet. In one case we had to apply two coats of varnish before we could print – one to take off the gloss, and the second to create the textured feel that had originally been approved. A cheaper substitute can look similar but can cause major headaches at the printing stage.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.