Labelexpo Europe 2025: Ancillary equipment

Ancillary equipment at Labelexpo Europe 2025 was geared toward increasing efficiency, quality and sustainability.

Ancillary equipment encompasses a broad gamut of different technologies, from aniloxes to applicators, from cleaning to curing. But despite the plethora of ancillary equipment on display at Labelexpo Europe 2025, there was a common theme to be found. These crucial products continue to be optimized to increase the efficiency, quality and sustainability of the label converter’s production environment and output.

Aniloxes

Acme Rolltech showcased its Advanced Channel Engravings (ACE) technology, which offers the advantages of tonal printing, including hexagonal engraving and the density of channel engraving. The company also showed its specialty aniloxes for embellishments: ATAC and ATAC2.0, Acme Tactile for screen-type raised effects; AHDW and AHDW 2.0, Acme High-Density White for opaque white printing for solids and text; AGLT, Acme Glitter for transferring glitter particles; and ATXR G and M, Acme Texture gloss and matte for texture effect.

Apex Europe promoted its GTT 2.0 engraving technology, developed as an alternative to traditional cell-based engraving. Unlike conventional rolls, the GTT design features a wave/channel that allows for better movement of ink, resulting in lower pressure and, therefore, no build-up on the back of the doctor blade.

“It has been a great show – our stand has been very busy”

Cheshire Anilox Technology launched a new anilox sleeve design developed to extend the sleeve’s lifespan by protecting its edges, and a new engraving designed to overcome the most common narrow web print issues and improve print quality. Also on display was Maxflo+, an innovative engraving design that has been refined over 12 years to enhance the transfer of ink to the plate, thereby reducing foaming, ink spitting, mottling, pin holing, plugging and dot gain. Cheshire also demonstrated its full range of engraving technologies, including TactiLoX for high-build tactile finishes and easyFlo HD for high opacity whites in a single pass.

Pamarco highlighted its latest innovations in anilox technology and surface engineering. Its next-generation coating Terolux is said to offer exceptional durability, superior ink release and high‑definition print performance even under demanding production conditions. The company also presented its range of precision-engineered anilox rolls, manufactured using proprietary laser-engraving techniques that ensure consistent cell geometry and volume.

Applicators/dispensers

Cab Produkttechnik demonstrated the Roxi label dispenser, designed for the precise supply of printed labels. Cab units range from ‘out of the box’ desktop devices to modular systems for installation into automatic plants. The new Roxi applies pre-printed adhesive labels at belt speeds up to 30m/min onto flat and curved surfaces.

Dispensa-Matic showed its ranges of US-manufactured label dispensers and applicators. With more than 40 years of experience, the company holds the patent on the first motorized semi-automatic label dispenser.

Open Data showed its range of handheld labelers, label applicators, various types of self-adhesive labels, and thermal rolls.

Ravenwood expanded its Nobac 40 range with the new airless Nobac 40B entry-level linerless label applicator. It applies labels up to 200mm long and 40mm wide around various bottle sizes, achieving application speeds of 75 bottles per minute. The company also introduces a new scanner for its Com 500 coating machine, delivering new accuracy levels. Ravenwood also launched a new Stripe Roller Support Shaft for the Com 500 Coater, replacing the traditional ETP locking bush system.

Cleaning systems

Alphasonics launched the DPH430-4 digital printhead cleaning system, which includes a nano-chemical cycle to supplement the advanced ultrasonics, and is developed to ensure complete yet safe cleaning of any printhead. David Jones, managing director of Alphasonics, says: ‘Nano chemistry effectively does the same job as ultrasonics, but chemically rather than mechanically, thus making it an ideal medium to operate in confined spaces. Nano-Surge Technology complements our existing ultra-safe Alphasound Technology perfectly to deliver impeccable cleaning of these expensive and difficult-to-clean items. We are very confident that this device will take printhead cleaning to a whole new level.’ The system on display could clean up to four heads at one time, but systems are available to accept more if required.

DC DruckChemie showed its range of cleaning products for every stage of the printing process, from plates to sleeves to anilox rollers and doctor blade chambers. The company ensures proper waste treatment during service visits and a reusable packaging concept that reduces environmental impact and waste. Cleaning fountains can also be rented.

Flexo Wash showed its full range of cleaning products and ran live demos of its Anilox Cleaning Liquid and Laser Anilox Cleaner. Also on display were the parts washer, plate washer and screen washer. The company also demonstrated its new anilox cleaner, which can clean four aniloxes with a 630mm face length simultaneously. ‘The trend is towards sustainability, reusing cleaning liquid, extending the life of the anilox rolls and minimizing waste,’ says CEO Anders Kongstad. ‘No one wants to do the dirty work, so we do it for them.’

Graymills Corporation presented its ranges of parts washers, inking systems and industrial pumps. Among the equipment on display was the PrintClean HP Indigo parts washer, a product which received ‘lots of interest’ according to Robert Stanley, managing director of Graymills’ UK distributor Stanley Press Equipment. ‘It has been a good show, we have received lots of inquiries,’ he said.

“Converters are focused on increasing productivity and getting more out of existing equipment”

Inglese introduced its LX-series plate-cleaning machines, which can be configured to be Industry 4.0-ready and with an automatic infeed conveyor belt. Inglese also showcased its new automatic anilox cleaners, which utilize high-pressure water, and a plate-mounting system engineered for labeling.

LaserClean demonstrated its ALCS 1000 anilox laser cleaning system. Designed for the narrow web market, the automated system has new software programs and can clean an anilox roll in less than five minutes. ‘Laser cleaning is the most sustainable method of anilox cleaning,’ says CEO Martin de Wit. ‘It not only removes pigments, but polymers, too. We’ve had lots of interest and are on course to sell at least four machines.’

Recyl presented Quick’Wash Resolv, its new cleaning technology for printing plates. This simple and effective cleaning technology is specifically designed to remove ink residues and impurities from plates contaminated with solvent-based ink.

Sitexco presented a laser cleaning system for anilox rolls, specifically designed for the narrow web industry. The company launched Sitexco Label L30, which extends the range to meet all modern cleaning needs.

Curing systems

Excelitas promoted the Phoseon Nexus One UV LED air- and water-cooled systems designed for flexo printing applications. They deliver high total UV power output to achieve increased print speeds. Nexus One comes with real-time remote monitoring capabilities. Also on show was a Phoseon FireJet UV LED air-cooled system, capable of curing at high speeds for small, medium and grand format digital printing systems. Visitors could also see the Phoseon FireLine UV LED water-cooled system, designed for a wide range of web and conveyor-based UV curing applications.

Giardina Graphic, a division of G Technologies Group, showed G-LED, a high-performance UV LED curing system. Thanks to liquid-cooled COB modules with controlled temperature, G-LED ensures high irradiance, optimal thermal management and consistent performance. The company also presented the new PN40, a UV LED module designed for narrow web presses. Developed to ensure maximum compatibility both with new installations and with retrofits of conventional UV systems, PN40 delivers high energy efficiency, operational precision and reduced consumption, supporting print widths of up to 660mm.

‘Participating in Labelexpo Europe is a key opportunity for us to meet with customers and partners, but also an opportunity to share how the experience we’ve gained over the years allows us to offer increasingly high-performance and sustainable solutions today,’ explains Samuele Guidolin, division manager.

GEW highlighted its latest LED products, the air-cooled AeroLED2 and water-cooled LeoLED2. Compared to the first-generation system, AeroLED2 provides a 30 percent increase in electrical power (70W/cm), a 30 percent increase in UV dose (170mJ/cm2) and a 40 percent increase in UV irradiance (26W/cm2). AeroLED2 is also ArcLED compatible. ‘It can be used on presses with web widths of up to 26in, which is important because there are many more of these wider machines in the market,’ says managing director Robert Rae.

Using the same fan and ducting arrangement as the E2C, customers can switch between UV arc and AeroLED2 on any print station.

LeoLED2 now has two power levels. Nilpeter was showing a FA-26 press equipped with LeoLED2 units running at 400m/min.

GEW also showed its ExciRay lamp systems, which enables converters to produce matte surfaces without the use of mattifying agents. The company also unveiled new process control tools, including the Dose Guard UV monitoring system, which provides closed-loop in-line control of the UV dose. ‘It has been a great show. Our stand has been very busy,’ says Rae.

Height-LED showcased a UV LED curing system with a service life exceeding 20,000 hours. The automatic width sensor adjusts the UV irradiation width based on print format, further reducing energy consumption and accurately detecting transparent films. Tailored UV LED lamp cassettes and mounting brackets are available for new and existing presses.

“We see enormous potential in the label market”

Hoenle launched its LED Powerline Web curing system, highlighting the technology’s flexibility, efficiency and compact design. The system addresses modern production line demands with precise UV material curing capabilities. It offers two wavelength options: the UVA version cures printing inks, while the UVC version crosslinks UV coatings, silicones and adhesives. The UVC module can be positioned in any location, providing adaptability across various production environments.

The system features efficient water cooling. Its hybrid nature enables switching between conventional UV and LED technology in existing processes.

Hoenle also displayed its UV Scan MACS dose measurement system and complete UV technology portfolio for drying and curing inks, coatings and varnishes, including UV LED, IR/Hot Air and Inert UV technologies.

IST Metz showed a new range of UV LED curing systems for label printing applications. LEDcure NX features AI-supported SMARTcure technology, which enables maximum efficiency in operation thanks to intelligent control. The portfolio is complemented by the new Freecure system, which is equipped with integrated UVC booster technology. This was developed specifically with the stricter requirements of the new printing ink regulation in mind, particularly for the reliable implementation of low-migration printing applications. All UV lamp systems are LED-prepared as standard and can be easily converted to LEDcure NX. This creates investment flexibility for future production planning. ‘We see enormous potential in the label market,’ says Arnd Riekenbrauck, sales manager narrow web at IST Metz. ‘Our aim was to develop cutting-edge technology that makes economic sense for both small and large label printers. With our new product line, we are convinced that we offer exactly the right answers to the challenges of this dynamic market.’

IST Metz’s UK-based partner IST Intech, also part of Metz Holding, was also at the show, presenting specialized systems for digital label printing.

“The relocation to Barcelona from Brussels has been a good move”

Lichtzen highlighted its UV/IR/LED printing portfolio, including UV LED retrofit systems, IR (NIR/MIR) LED drying systems and UV inks specifically optimized for label and packaging applications.

UV Ray presented its MaxLED lamps with a new air-cooled technology, complementing its water-cooled systems. The new air-cooled version maintains consistent temperature and emission performance throughout its lifetime, offering long-term energy and cost savings. It features a compact, modular design and precision-managed power for various UV curing applications. It can also be configured in hybrid set-ups with UV Ray’s mercury lamps. The company also highlighted MaxLED as a retrofit option for straight-path presses and debuted its Goliath UV reflector, delivering uniform output with lower web temperatures.

Doctor blades

Agergaard Group presented AkeBoose Nova TK, an all-in-one chamber doctor blade system, engineered for label, folding carton and flexible packaging flexo printing. Combined with the compact, low-pulsation, energy-efficient EPP100 peristaltic pump, suitable for both UV and water-based printing inks and coatings, the system enables a resource-efficient, closed ink circuit for elevated print quality and efficiency in flexographic workflows.

Esterlam showed its new-generation doctor blades, which use the latest developments in advanced polymer technology to provide instant start-up, enhanced print quality, longer blade life and improved operator safety, according to the company. Giving a uniform ink film across the entire anilox, Esterlam synthetic doctor blades have been proven to reduce dot gain, meaning less material usage and faster job changeovers. Requiring less pressure, Esterlam’s self-lubricating blades will reduce wear and scoring to the anilox and increase doctor blade life. The unique edge profiles offer consistent performance and help eliminate ink spitting.

Flexo Concepts showed two new polymer doctor blades. TruPoint Polylam can replace steel blades in all applications and reduces wear on the anilox rolls. TruPoint Edge is a longer-lasting blade for specialty applications. CEO Kevin McLaughlin says: ‘We’ve had excellent response to the new blades. We’ve been selling them for a year, but this is the first time we’ve had them at a show.’

PrimeBlade showed its ranges of doctor blades, with particular focus on its Nano Series, which features nano‑technology integrated into the steel. Ronny Eriksson, head of sales, says: ‘The nano-technology helps to provide extra-long life. Whereas our competitors use ceramic coatings, which are harder to recycle or cannot be recycled at all, our doctor blades are recyclable and feature 95 percent recycled steel.’

TKM showed NEOFlex, its latest patented doctor blade technology. Thanks to its innovative blade tip, the pressure can be reduced by up to 40 percent. This leads to lower wear on doctor blades, end seals and anilox rollers (including scoring lines and general wear). The tip ensures consistent ink transfer to the anilox roller. ‘We’ve had a lot of great feedback and many leads,’ says product manager Julian Stüven. ‘The relocation to Barcelona from Brussels has been a good move.’

Testing equipment

ChemInstruments offers a comprehensive range of precision instruments designed for quality control, research and development. These instruments are engineered to test the performance of pressure‑sensitive adhesives, labels, tapes, films and substrates according to key industry standards, including PSTC, ASTM, Finat and TLMI.

CISC Semiconductor showed products designed to boost the productivity and quality of RAIN and NFC inlay and label production. CISC’s RFID Xplorer in-line production tester provides real-time analytics for quality assurance, encoding and process control. The company’s tools empower manufacturers to identify and eliminate defects early, ensure compliance with RAIN standards and achieve higher yield rates.

RK PrintCoat Instruments showed its FlexiProof 100 machine, which incorporates a custom-designed UV LED unit, an alternative to the dichroic mercury arc vapor lamps currently used. It utilizes a doctored ceramic anilox roller and a photopolymer plate, allowing for realistic printability testing at a maximum speed of 100m/min on all types of flexo substrates. RK also showcased its VCML Pilot coater, the GP100, K303S Multicoater, Esi Proof, KLOX Complete and K Hand Coater.

Voyantic introduced the upgraded Tagsurance 3 system, a comprehensive system for measuring the performance of UHF and HF RFID inlays, tags and labels in different stages of the production process, from chip attachment to label converting and incoming inspection. Additionally, Tagsurance 3 enables the encoding of RAIN RFID labels on high-speed machines, eliminating the need for external encoding solutions and streamlining production processes.

Web guiding/monitoring

Erhardt+Leimer launched the Elscan OMS5 web monitoring system, which uses two high-resolution 18-megapixel cameras, each with distinct fields of view. In addition to the higher image quality, the dualView technology enables delay-free digital zooming up to the highest magnification level, eliminating the need for motorized lens adjustment.

“Participating in Labelexpo Europe is a key opportunity for us to meet with customers and partners”

Re unveiled the latest evolution of its established ReVision NET system, debuting with a new web tension controller that offers improved response speed, precision in web tension control, and an intuitive touchscreen. Also on display were the company’s web guiding systems and edge sensors for achieving optimal web alignment and process stability.

Renova showed its new Futura web guiding system. It features an actuator and rotary sensor integrated into the roller body, allowing for quick and easy installation and ensuring fast and precise web centering even in the most compact systems. The all-in-one technology of the Futura system reduces mechanical backlash, misalignment drift and the typical issues of physical pivots such as friction and wear. The Futura web guiding system is available in single or double roller versions.

Miscellaneous

Baumer showed its Xdot digital UV varnishing system. The system is capable of jetting raised braille text to the Marburg Medium standard and offers high abrasion resistance and excellent readability. The company also promoted the modular Xtend³ controller, offering a user-friendly interface, automated job management, and quick text and data import.

ContiTech presented its latest portfolio, which includes precision rubber printing blankets by Conti-Air, Phoenix Xtra Blankets, Printec, Rollin, Sava and Vulcan, for offset printing and sheet-fed applications, as well as flexographic printing forms for direct engraving by Conti Laserline and the Axcyl Flexo Plate Mounting sleeves.

Double E promoted its ranges of cores and core cutters, roll handling equipment, waste management and handling systems, and web guiding and tension control systems.

IEEC Power Electronics showed its latest compact and efficient corona treatment system designed specifically for narrow web and label printing. The system could also be seen in action on a press from Multitec at the show.

Lang showed a range of engraving machines, including CNC engraving machines of the Impala series, designed for milling of embossing dies, male and female dies and smaller cylinders. For bigger cutting and embossing cylinders, LANG offers the RM series. The complete system also includes the Pulsaris 300FS laser engraving machine, which features an ultra-short pulse laser for creating special effects, as well as a 3D software package for designing creative and complex projects.

Lenze presented the compact multi-axis servo drive i750 for precise motion control. The company also showed the intelligent i950 cabinet servo drive for demanding servo applications, which easily integrates into modular machines, and the C520 controller, featuring high computing power for demanding motion control in compact machines.

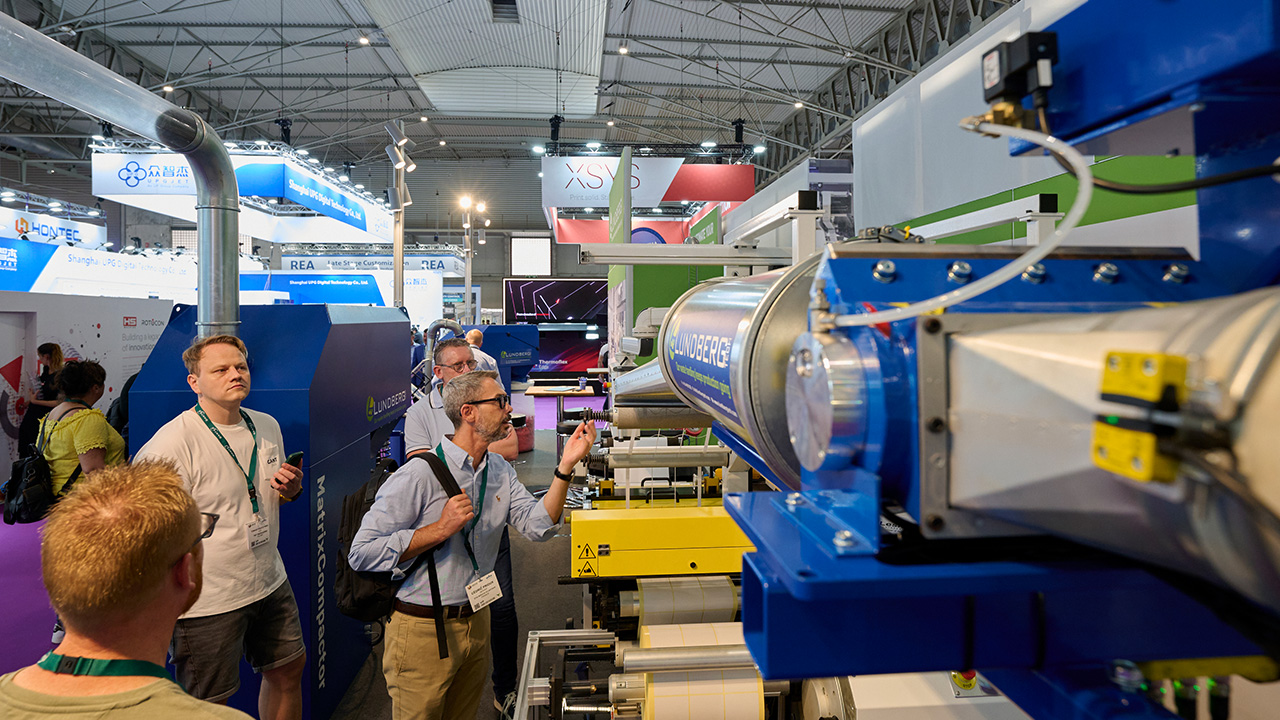

Lundberg Tech unveiled the new generation MatrixCompactor 160, a waste-capturing system designed to handle label matrix waste from one press. The system enhances production by capturing and compacting label matrix waste, reducing the use of virgin materials, cutting transport-related CO₂ emissions, eliminating unnecessary disposal of paper cores and easing physical strain on operators.

Macsa ID showed its coding and marking systems, including laser coding and track and trace systems. Among the technology on display, BlueBox allows laser coding directly on cardboard boxes, eliminating the need for labels, inks and adhesives. ClearPix performs laser coding on PET bottles with permanent, high-resolution marks. iLumiFlex is a UV coder for flexible packaging applications.

Martignoni launched Labelfles C109, a new high-performance corona treater.

Matho highlighted the Cuttobag (CB), a compact unit that integrates cutting, extraction and collection into a single, space-saving design. Suitable for film, label and edge-trim waste, the CB offers quiet operation, low operational costs and high cutting performance. Also featured was Matho’s line of cutters, engineered for energy-efficient granulation of production waste.

Meech showed its range of static control and web cleaning equipment. Among the systems on display was the Hyperion ionizing bar product series, including the 945IPS Mid-Range Ionizing Bar launched earlier this year to improve safety and enhance product quality for mid-range applications, and the Hyperion 650QAC, designed for ESD-sensitive applications such as label printing with integrated RFID chips. ‘Converters are focused on increasing productivity and getting more out of existing equipment, and our products can help them to achieve that,’ says sales director Ian Atkinson. ‘The show has been great and exceeded our expectations.’

Novacore showcased high-precision paper cores, produced with strict dimensional tolerances and consistent, repeatable quality.

Pluriservice Group demonstrated its modular Apix Cobot print apply systems. The company also promoted a wide range of software, including VisionTech for monitoring the vision station, Sentinel Software for centralized monitoring, real-time production monitoring software, E2K Collect Enterprise Software for data collection on Android devices, E2K RF Software for warehouse management, and E2K Spooler for print automation.

Qualivision exhibited its label overprinters and print-apply systems.

Rossini demonstrated its ranges of sleeve systems and printing cylinders.

Tootech promoted its laser barcode label printer, the TTE-72FK, which prints on the middle layer of labels, with a maximum size of 108 mm x 108 mm and a resolution of up to 2,000 DPI.

Valco Melton presented its LP Series Coating Lines designed to coat and laminate a variety of substrates using hotmelts or UV hotmelts, offering complete control of the coating process through programmed recipes and closed-loop capabilities. The company also promoted Akura Applicators, which feature independent hydraulic zones, each fed by a gear pump, to ensure uniform adhesive distribution. Coupled with Weight-Inspekt, the equipment enables real-time grammage measurement and closed-loop control.

Weight Inspekt automatically corrects the flow rate in the out-of-tolerance hydraulic zone when a grammage deviation occurs.

Visitors could also see Coat-Inspekt, which offers real-time vision inspection for coating processes, providing an immediate and intuitive overview of the production status.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.