★You are viewing this content as a subscriber

★Subscribers only

Understanding forming, filling, sealing and lidding operations

Examining the different sealing, filling and forming methods and machine requirements

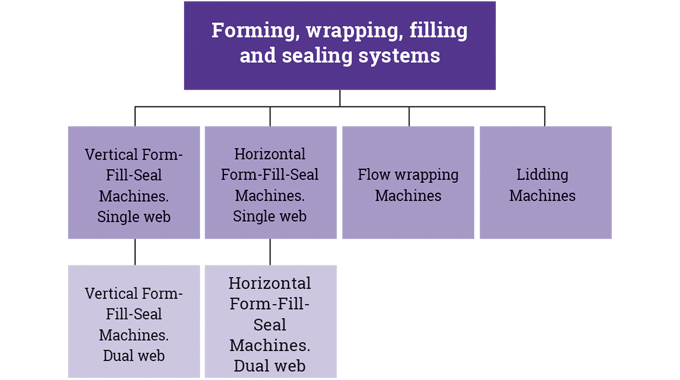

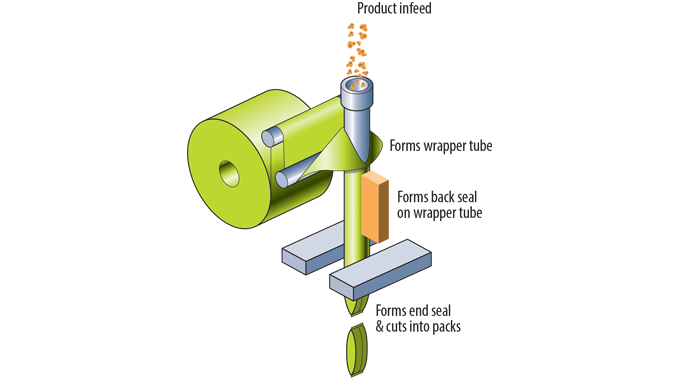

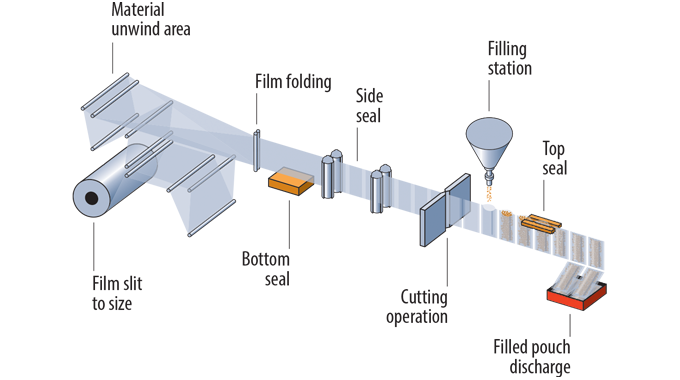

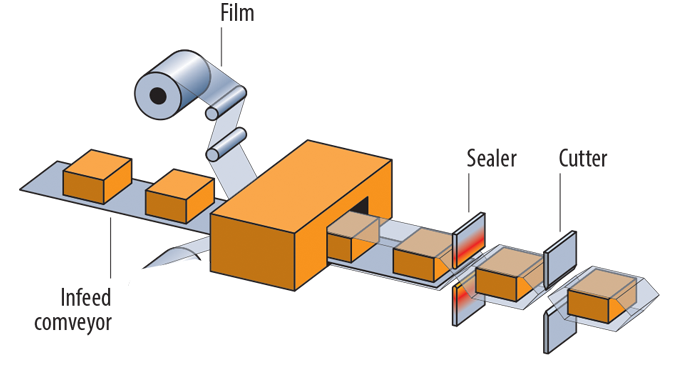

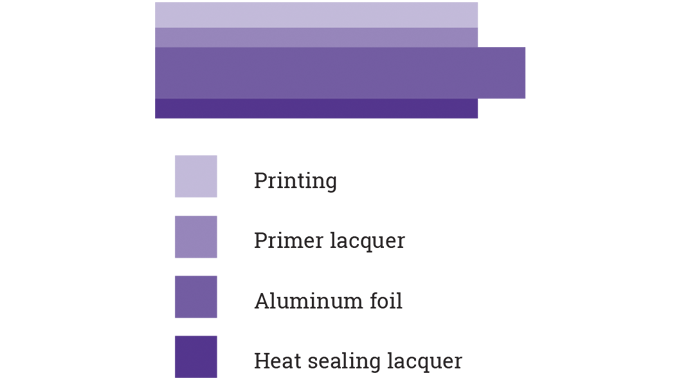

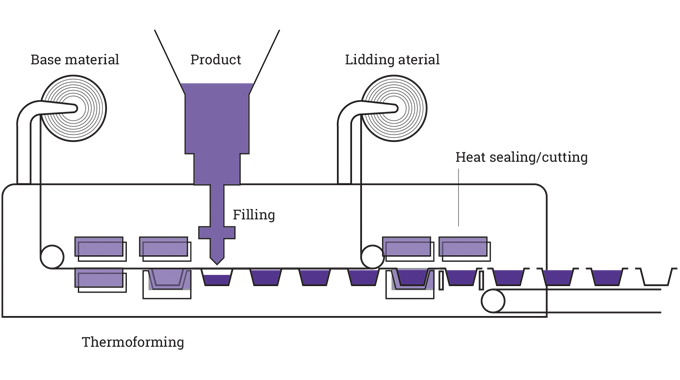

When labels have been printed and converted into their finished size and shape they will be sent in reel or cut-stack format to the packaging plant for applying to the required bottle, can, jar, tub or other packaged product. Flexible packaging goes through a similar type of printing and converting process before being sent to the packaging plant in slit reel or die-cut format to either go through a forming, filling and sealing machine operation, be flow-wrapped around a bar or other solid product, or applied as lidding or capping to filled pots, tubs, jars, etc.

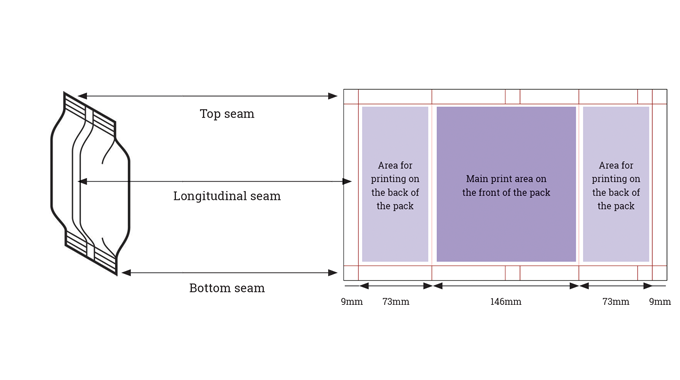

In a different article, the many different types of flexible packaging products were described. They included wrappings, bags, sachets, pouches, and lidding. Some packs were noted as being quite small, or long and thin, while others can be fairly sizeable. Some need to be filled while the pack is in a vertical position, using either a single web or a dual web machine; others need to be filled or wrapped horizontally.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.