Digital capsules

A manufacturer of wine capsules has set up a pioneering digital printing operation. Andy Thomas reports

Spanish company Canals, based near

Canals was formed in 1947, originally making beer bottle caps before moving into wine capsule manufacturing 25 years ago. The family-owned business employs 150 people.

‘We want to change the mentality of our customers by allowing a complimentary design on the capsule and the wine bottle label,’ says Canals general manager Guasch Soler. ‘The capsule is now a marketing product, and this means we need to sell it to the marketing people and not the technical buyers, on value and not on price.’

With its digital operation, Canals is able to print – including sequential numbering – run lengths down to 3-5,000 capsules. ‘It is also important that we can print samples on the final substrates,’ says Guasch Soler.

To promote the concept, Soler employed high profile marketing guru Luis Bassat, the brains behind the publicity campaign for the Barcelona Olympic Games, and worked closely with Barcelona-based label converter Germark and HP.

Guasch Soler acquired his first digital press, an HP Indigo ws4500, in 2008 and after a lot of development work, applied for patents for the process of digitally printing wine capsules in 2009. The company is now signing up distributors in Europe and the

Canals went on to install a second ws4500 and its latest acquisition is a more productive WS6000. ‘Digital printing is more expensive, but we want to change all our printing systems to digital,’ says Soler. ‘In comparison, traditional gravure printing is dirty, uses solvents and requires constant manual adjustment of color, while waste is much higher. In terms of social responsibility we want to reduce our use of solvents and eliminate them within five years.’

Technical challenge

The key technical challenge overcome by Canals – and the subject of its patent – is the ability to prime the capsules with the print-receptive coating required by the HP Indigo printing process.

Capsules were originally made from tin, but are now either aluminum/polyester laminates or PVC, depending on final market segment. ‘Perhaps 60 percent of the capsules we produce are PVC for the cheaper end of the market, against 40 percent poly-laminate,’ says Soler.

These substrates are primed prior to printing, and varnished post-printing. ‘The primer had to be developed in-house at Canals because the standard primer would not work on the poly-materials, which are 3-4mm thick,’ recalls Soler. ‘Another issue we had to overcome is static – especially for the PVC.’

A good, opaque white is also very important for printing the capsules. Canals did trial inkjet before settling on the HP Indigo. ‘We trialed a Dotrix, which gave us good results, but the problem was the whites, and we found we would have to use flexo white – not good for small quantities,’ recalls Soler. ‘If inkjet can get an opaque white, it will be very good, but we are happy with the HP whites.’

Future plans

Looking to the future, Canals is looking to expand its market reach into restaurant bottled water, which is, in

The company also has ambitious plans for its on-line presence. A new website will allow customers to track their jobs, and will contain ideas on how to market digitally printed capsules – for example through a ‘capsule of the month’ feature. ‘We aim to get very close to the final customer, like Carrefour or a Tesco to show them how fast we can react to new marketing campaigns,’ explains Soler. ‘A winery can come here and get a capsule designed and produced in two days. We actively cultivate designers to show them the possibilities.’

Artwork comes either direct from design agencies, or Canals is asked to match a particular front label design. ‘Color matching pantones accurately onto aluminum laminates and PVC is our expertise,’ says Soler. ‘We are working on our own pantone swatches from our own R&D. We can both mix solid colors, or make them out of up to seven colors.’

Soler is looking to expand his partnerships with label converters who have digital presses, enabling him to offer complete, color-matched bottle/capsule decoration solutions to wineries. This looks like a major future opportunity for digital label printers.

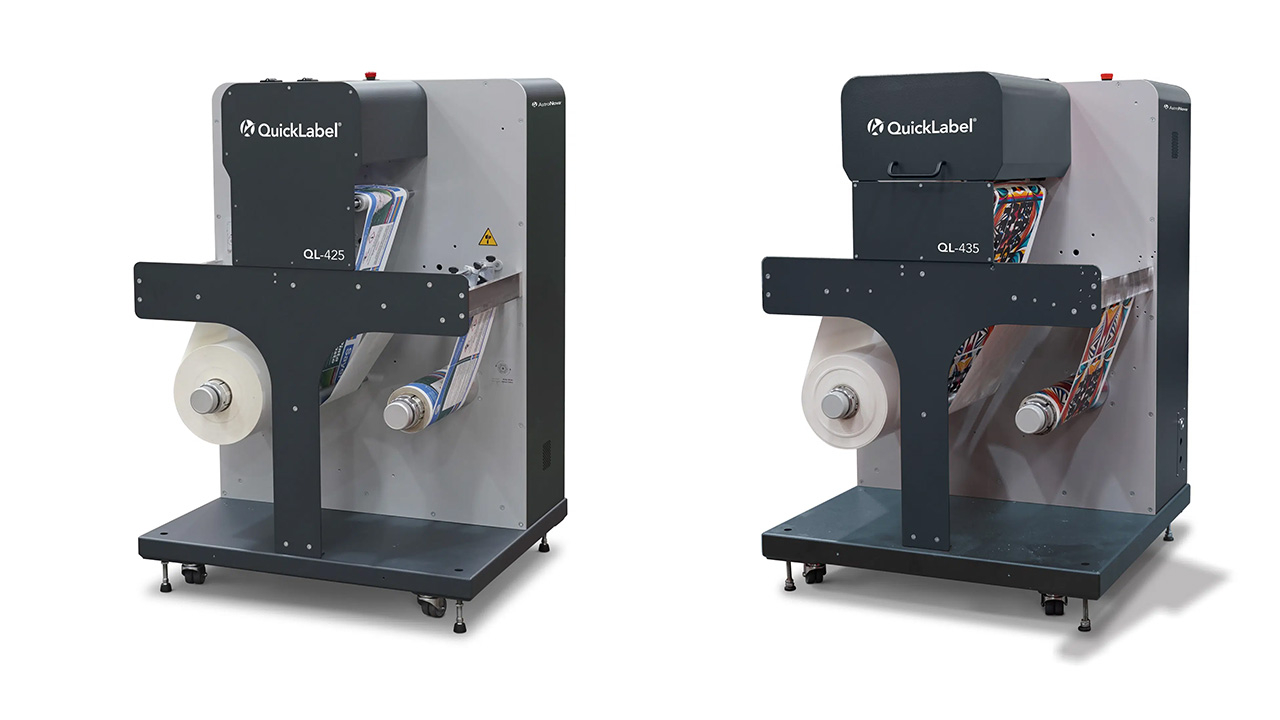

Pictured: Canals has scored a world first by printing capsules like this digitally

This article was published in L&L issue 4, 2010

Click here for more stories about Canals on L&L.com.

Click here for more stories about HP Indigo on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.