Drupa 2012 preview

Drupa is the world’s biggest and most comprehensive commercial print show, but also sees the launch of many products of interest to label converters. Andy Thomas rounds up a selective list

ABG

ABG shows converting lines on the HP stand in Hall 4 demonstrating its ability to offer finishing solutions for digitally printed labels, flexible packaging and cartons.

Exhibits will include the Digicon Sabre Xtreme laser die cutter with UV flexo and over-laminating modules and a Digicon series 2 converting line equipped to run both labels and folding cartons with an HP Indigo WS6600 Digital press both in and offline. A Digicon Lite, label converting system will highlight the company’s entry level, low cost option for converting digitally printed webs.

AVT

AVT shows its PrintVision/Helios II installed on an HP Indigo WS6600 digital press, demonstrating print inspection and verification of variable data. Drupa also see the introduction of SpectraLab as an add-on module to the Helios II family, featuring in-line spectral measurements.

It provides absolute color measurements in L*a*b*, to match with brand owner’s color standards and design. Also new is an upgraded PrintVision/Argus Elite, featuring pressure setting from the image, which is demonstrated on the new F2 Comexi press on the Comexi stand.

The PrintVision/Jupiter system will demonstrate RightSeal, the improved dual optic head operation for cold seal monitoring, as well as iReg, a semi-automatic registration setting for CI Flexo presses. This system will also be equipped with SpectraLab.

Apex Group

Leading ink, plate, and software suppliers to the flexo industry have joined Apex to create a flexo Pantone simulation guide for release at drupa based around the company’s GTT (Genetic Transfer Technology) ink metering technology.

Offset printers can now use GTT-Offset cylinders, for coating/lacquer applications, and claimed advantages include higher gloss points, less foaming, easier cleaning – and typically less drying time and lacquer usage.

Apex also previews its X-Sleeve project: next-generation lightweight and durable plate-mounting and bridge sleeves. Finally there is the BioClean anilox cleaning and maintenance package which offers ‘earth-friendly’ anilox (and GTT) sanitizing solutions with more convenient packaging.

BST International

On the largest booth in the company's history BST International shows QCenter and QCenter.Spectral, two developments claimed to set new standards in the production control on running webs.

The inline spectral measurement system QCenter.Spectral makes it possible to obtain both reliable inline and offline data on specified colors over the entire print run.

Working in close partnership with X-Rite, this makes the results of inline measurement and measurement with stationary handhelds comparable for the first time. This will set a new industrial standard for color quality control and workflow simplification, says the company.

QCenter is a modular product line for centralized control functions including web inspection and 100 percent inspection. Via the intuitive touch screen interface, the operator controls any actions such as color measurement, zooming, selection of image details and monitoring of the entire web width. In addition, QCenter features the one-to-one display of the complete repeat in high resolution HDTV quality.

Also new is ekr 500 D, the digital enhancement of the successful web guiding controller ekr 500 Plus. By changeover to digital technology ekr 500 D provides simpler connectivity and ease of operation. In combination with the newly designed CompactGuide rotating frame guide, the customer gets a Plug & Play system for a broad range of web guiding tasks.

DigiFlex

DigiFlex is to launch its Flexojet1725 Inkjet Computer-to-Plate system for flexographic, dry-offset and letterpress plates. The FlexoJet1725 inkjet CtP jets DigiFlex Bi-component ink on any flexographic analog plate to create a mask, replacing the black ablation layer found on standard digital flexo plates.

The system can also be used to produce dry-offset and letterpress printing plates.

Domino

Domino will show the latest version of its established N600 inkjet press. The Domino N600i offers 600dpi resolution on up to four grayscale levels on paper or filmic substrates and is rated at 75 meters (246 ft) per minute.

The enhanced i-Tech features largely revolve around increased automation with reduced need for manual intervention, leading to quicker changes and more consistent print quality. Integral with the N600i is Domino’s i-Tech CleanCap automated cleaning and capping station. By reducing expensive downtime, and working with the ActiFlow ink circulating system to keep ink flowing around the print head at all times, print quality is more consistent.

DuPont

DuPont has announced full commercialization of DuPont Cyrel DigiFlow, a new digital workflow enhancement designed ‘to expand the capabilities of digital Cyrel and digital Cyrel FAST to deliver superior print quality and productivity’.

Cyrel DigiFlow is a relatively simple and inexpensive modification to the existing line of DuPont exposure units; it adds a chamber that allows the creation of a controlled atmosphere during the main exposure allowing one-to-one reproduction of image elements on the plate. This one-to-one reproduction is critical to optimizing the effects of solid screening patterns.

The Cyrel DigiFlow exposure units were designed for use on an ‘as-needed’ basis, and can easily be switched off when the standard digital dot is the preferred result. Because of the low cost and the flexibility of Cyrel DigiFlow, DuPont believes this is the simplest and most cost-effective solution for those flexographers wanting to seamlessly switch between standard and hybrid dots.

Edale

Edale will be promoting its current range of printing and converting machines with a strong focus on the packaging and folding carton market, catering for offset printers diversifying into the flexographic print process.

EskoArtwork

EskoArtwork describes its new Suite 12 as a major update to its software suite for the packaging, labeling, sign making and display industries, writes Barry Hunt. It includes new releases of its flagship applications: ArtiosCAD, ArtPro, PackEdge, DeskPack and Studio which create automated workflows with color management and artwork creation for the various primary and secondary packs from pallet cartons to the retail shelf. Suite 12 also offers a series of 'walkthrough' visualizations of product packs in retail environments for brand owners.

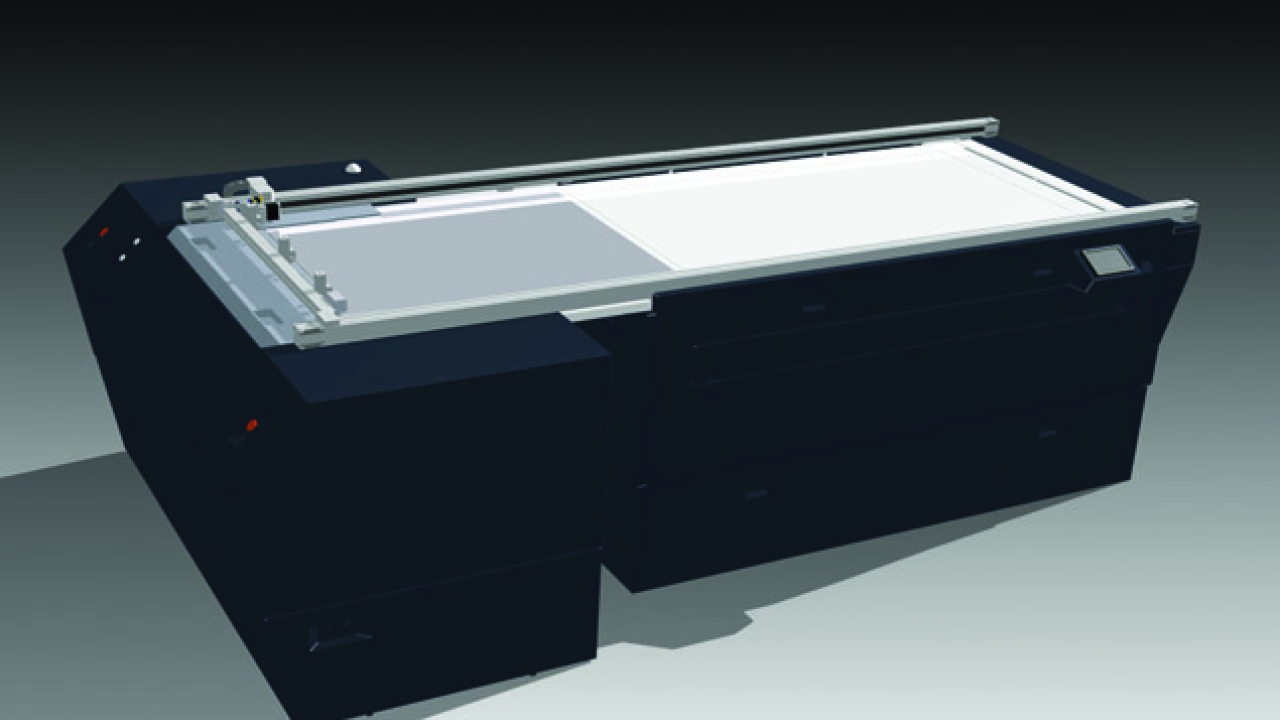

The CDI Spark 4835 Auto is said to reinforce Esko's dominance of the digital flexo platemaking market from when the first CDI was introduced in 1995. Based on ablation masking, the new platesetter has automatic plate loading and unloading. It features the digital Inline UV2 back exposure unit which gives a choice of dot structure. This technology is also seen on the CDI Spark 2530, equipped with magnetic drum.

Esko also features the latest quality-led developments with HD Flexo platemaking, which has reached 400 installations worldwide. They include HD Flexo Pixel+ technology. This is an optical, electronic and screening enhancement for HD Flexo imaging to support flat-top dots creation for different plate vendor flat-top dots offerings like DigiCorr, DigiFlow, Lux and Next. It leads to a substantial increase in solid ink density says the company. It also features the inclusion of digital main exposure built into the CDI imager (Inline UV2). The combination of innovative imaging and screening technology is said to allow users to control the shape of different dot structures in one single plate.

The new Kongsberg XN finishing table, shown with an upgrade of the i-cut Suite, is said to offer increased flexibility at an affordable price. Applications range from carton printing to signage and display. Partnerships featured at drupa include Agfa, Durst, EFI, Fujifilm and HP Indigo.

The company is one of six technical partners for PantoneLIVE from X-Rite Pantone. At drupe, it will promote the first integration of the PantoneLIVE color control system within the packaging supply chain. It is combined with Esko's Color Engine system.

Enfocus introduces PitStop11 (PitStop Pro and PitStop Server 11) for PDF preflighting and correction. The company says there are over 130,000 PitStop users since the first version appeared 15 years ago. Also making its debut is Switch 11, a modular software system to automate repetitive FTP file handling tasks. It integrates with existing systems and drives third-party graphics applications, including MIS.

FFEI

FFEI will showcase a new, end-to-end, digital labels solution, which includes a Caslon digital inkjet press incorporating a new digital spot color unit printing white ink, and FFEI’s latest RealPro workflow software.

‘This solution enables label converters and digital print houses to partner with one technology supplier where all components are designed to work together,’ comments Andy Cook, FFEI managing director.

Caslon is a digital color inkjet press jointly developed between FFEI and Nilpeter, can be installed as part of a traditional narrow web label press or utilized as a standalone digital inkjet system, converting high quality labels up to 420mm web widths, at 25m per minute rising to 50m (dependent on resolution).

New for drupa 2012, and available from FFEI and reseller partners, is an additional Caslon digital spot color unit that prints digital UV-curable white ink. This new capability eradicates the need to pre-print white ink via a traditional press – shortening production times, minimizing cost and providing increased job control.

In addition, FFEI Caslon customers can now benefit from the newly enhanced RealPro Workflow System, a fully automated production solution for commercial, digital and label printers. New specialized labeling and packaging features enable seamless integration with the Caslon digital inkjet press, providing users with the ability to centralize control of their files and intelligently output them via the most cost efficient route, whether on a digital or conventional output device, or a third party system.

Visitors to the FFEI stand will also see live demonstrations of RealVue 3D Packager, a 3D visualization software option for fast carton packaging or label prototyping.

Focus Label Machinery

Focus enters the digital print market with its new d-FLEX inkjet press. The press adds full color inkjet heads into the company’s existing Reflex servo press along with an inline UV flexo print head, die cutting, slitting and rewinding. Focus will demonstrate high quality variable images, overprinted in perfect register with UV flexo ink, then converted and rewound in a single pass.

In another new development, Focus extends its Centraflex model from water- and solvent-based to a new UV model designed for printing and converting a wide range of unsupported substrates including shrink sleeves and casings.

In order to stabilize the substrate temperature whilst subjected to the heat of the UV dryers, the Centraflex UV press will incorporate a water-cooled C.I. drum, using chilled water, together with air-cooled lampheads on each print station. The increased drum diameter allows extra space for the drying system and gives good access to all six print stations. For casings, the optional turn bar system will enable the substrate to be printed on both sides simultaneously, allowing up to six colours to be printed in register front and back (6 + 6 color printing). Also, an integral scraper blade system will be employed to remove any excess ink when casings are printed right up to the edge, without creating a build-up of ink on the CI drum.

For textile labels and ribbons, Focus will launch the bench top B4 Letterflex. This new design offers up to four colors, with options for reverse side printing and multiple ribbon printing. A new, halogen lamp drying system enables production speeds up to 60 m/min.

Fujifilm

Fujifilm looks set to launch its Flenex DLE (Direct Laser Engraved) platesetter. To shown at Drupa with Fujifilm’s new Flenex WV-1 plate, it is designed for carton, flexible packaging and label applications and available for UV or water based inks.

Gallus

Gallus will demonstrate new inline decoration options on its ICS 670 carton press including a new gravure printing unit which can be integrated at any point in the machine and can use both water- and solvent-based inks. Cylindrical gravure sleeves help reduce operating costs and a shorter web path with various dryer options helps reduce waste. New inline modules for laminating and cold foiling on transparent films will also be shown. Gallus' HiDef flexo printing system will be introduced. It involves a combination of temperature-controlled anilox rollers, dynamic printing pressure adjustment and matched inking systems and printing plates.

The show also sees a new blank ejection option for the Gallus FCL flat-bed die-cutter. A 100 percent inspection system detects faulty blanks, which can then be ejected on a lane-by-lane basis with no restriction on blank length. Up to eight lanes of blanks can be monitored individually.

Grafisk Maskinfabrik

On Xeikon’s booth in Hall 8a B44-1, GM will show its DC330 converting line for self-adhesive labels inline with a Xeikon digital label press. Being modular, it offers a wide range of techniques – semi-rotary die-cutting, laser die-cutting, screen printing, hot stamping and more. A unique buffer system allows the operator to change rolls while the press is running.

The DC330 mini will be shown in an offline configuration on the Epson stand, Hall 5 A0, where the GM team will be based during the show. A flexible converting line for self-adhesive labels, the DC330 mini features UV varnish, semi-rotary die-cutting and slitting. It can run inline or offline with the Xeikon 3000 series, HP ws4500 and WS6600 series and Epson SurePress. It is the first converting system that can run inline with the HP WS6600 press.

GM will also display a LRW jumbo unwind/rewind web system designed for inkjet printing on the Domino stand, Hall 13 D89. The system is an integrated part of the N600 digital press, and can work as a stand-alone unwinder/rewinder for a press or as a completely integrated unit.

GSE Dispensing

GSE Dispensing demonstrates a new software interface that integrates seamlessly with the printer’s IT system. The MIS interface provides real-time information such as ink availability, ink recipes and an immediate overview of ink costs per order, enabling a more responsive print value chain.

A GSE associated company Print Proof Solutions will also display its Perfect Proofer at the drupa stand, an automated, table-top wet-proofing solution.

Honle Group

The Honle Group will be demonstrating the latest advances in UV-LED curing, including the LED Powerline, a compact, high-performance array used for pinning and final curing in inkjet printing. The LED Powerline is available in wavelengths of 365/375/385/395/405nm. The length of the array is variable in 40mm steps and can be extended to over 100 cm.

Also new is the Eltosch ECOPower Dry, a modular IR/HA dryer for sheetfed presses. Each drying segment contains its own supply unit with integrated fan, damp register and microcontroller, which allows individual programming.

The Honle Group also shows a nitrogen-inert UV printing system for low-migration inks. High-speed inertization reduces the concentration of photoinitiators and thus migration levels.

INX

The company shows its Evolve Advanced Digital Solutions line of equipment, which includes the new NW140 digital narrow web press with UV LED-cure single pass output, the CP100 cylindrical printer, and the MD series of flatbed printers.

INX offerings at drupa continue with various inks, coatings and color management options. Company experts will also discuss low migration packaging ink technology, including the European Printing Ink Association’s newly updated guidelines and requirements.

INX also shows its print quality analysis support and Device Link Solution that optimizes total ink coverage while reducing ink consumption for both traditional and digital printing.

Isys

Isys will launch its EDGE 850 desktop label printing system at the show. The digital press will print variable data on die cut or roll substrates at speeds of eight m/min (25ft/min/ 6ips) on a wide array of media. The company says applications will include beverage, food and consumer product label printing.

K2

UK-based press manufacturer, K2 International will exhibit a 6-color FastAction flexographic press. It will be equipped with full UV curing and servo drives to enable both label and film packaging substrates to be processed and will incorporate a digital print head for variable data and barcodes.

The FA Fast Action press is available for both narrow and wider web labels and packaging applications up to 800mm. ‘While our core competence has been in labels, we also manufacture wider web presses to meet the demand for packaging such as shrink and wrap around labels as well as specialized applications,’ says managing director, Russell Oddy. ‘For example we recently supplied an 800mm wide press for printing butter wraps equipped with drying systems for both solvent and water based inks.’

Standard equipment for the FastAction press includes PLC touch screen controls, automatic web tension, print and die stations of equal height for safer operation, ceramic anilox rolls and fast action print and die stations. Options include rotary cold foil stamping, UV laminating, sheeting, fan folding and video web inspection and remote diagnostics.

Kodak

Kodak will launch 10 new products from flexo plates to the latest high-volume digital inkjet presses, involving 30 individual industry partners, writes Barry Hunt.

Kodak will feature the Spotless Flexographic Solution for its established Flexcel NX flexo plate system. It is said to reduce spot color printing – meaning fewer plates and changeovers with faster make-readies – combined with gravure-like quality. This technology forms the basis for the new Flexcel Direct System for producing in-the-round flexo sleeves for package printing using direct laser engraving technology. Kodak claims it offers an affordable and energy-efficient approach to producing the press-ready elastomer sleeves with consistently high levels of print quality, while contributing to fast press set-up times.

Kodak will also launch Sonora XP, which is the latest iteration of its thermal direct offset plate system. As a waterless processing method it offers environmental benefits with lower operational costs and labor. Aimed at emerging markets, the Kodak Achieve is an entry-level thermal CTP system, complete with platesetter, plates, workflow, processing and chemistry.

LabelTraxx

Narrow web MIS specialist LabelTraxx introduces Digi Traxx, a powerful new tool for simplifying the prepress functions associated with multi-version label jobs in a digital environment. Digi Traxx imports line item data via XML directly from an existing MIS system, laying out the job ticket in the most efficient and productive manner. Digi Traxx creates the necessary JDF files and sends them to Esko Automation Engine AE10, where press-ready layouts are automatically created for printing, including step-and-repeat and markup insertion.

The company highlights two new offerings: a pharmaceutical track and trace system for serialization of pharmaceutical cartons and the C350 High Speed Tipping feeder which is able to accurately place leaflets, coupons and other pieces onto a carton on a folder gluer at speeds up to 70,000 pieces per hour.

Melzer

Melzer demonstrates its SL-600 RFID converting line. With up to 60,000 products/h this machine is designed for industrial production of small-sized RFID labels for alcohol brand protection, pharmaceutical fraud protection, vehicle identification and other high quality mass applications . The system incorporates testing and selection of UHF transponders in a 6-track stop and go process, ensuring only ‘live’ chips

are selected. Melzer also demonstrates a fully automatic production line for e-cover inlays based on plated antennae plus lamination. For high productivity, the system includes selective antennae testing and chip connection by soldering.

Mitsubishi Paper

Mitsubishi Paper shows its new CTP system, Violet DigiPlate (VDP) and the newly developed silver nano particle technology for the printing of functional electrical circuits.

Phoseon

Phoseon’s UV LED curing technology will be showcased at OEM partner stands throughout the show, with both air and water cooled products based on patented Semiconductor Light Matrix (SLM) technology that utilizes proprietary packaging, optics, and thermal design.

Polar

Polar will demonstrate the latest version of its LabelSystem automated cut & stack finishing system. The basic LabelSystem DC-11 will be shown together with a LabelSystem DCC-10 counter-pressure die-cutting machine with a new loading system. The LabelSystem SC-10 will be shown with a new automatic air-board removal system. Also new is the BM-105 manual multi-station banding machine and the Polar LabelSystem SC-25 with log banding.

This ink manufacturer launches new UV flexo formulations for shrink films and labels. The SLM Flexwrap Series of UV inks and coatings offer a range of EuPIA compliant formulations for shrink film and indirect food packaging applications. These inks do not need primers or protective varnishes. The SG series offers similar characteristics but are not intended for food packaging. Both offer high adhesion and shrink characteristics of more than 70 percent.

SF010, is a UV curable, silicone-free opaque white ink for rotary screen printing. The ink is formulated to permit use as a first-down white for subsequent over printing by flexo, letterpress and litho as well as screen inks or varnishes.

The new range will be complimented by EL088 a UV flexo, semi-gloss release varnish for peel and read applications and the RLM series of metallic gold and silver inks and foil effect brights for flexo, screen or letterpress printing. Both products are suitable for use on coated paper and board and treated PE, PP and similar substrates.

QuadTech

QuadTech introduces the SpectralCam HD color measurement system, an inline high-definition dot viewing and web stabilization system which enhances the company’s existing spectral color measuring system. The HD variant facilitates on-the-fly detection of dot abnormalities such as pin-holing, bridging, doughnuts and halos. Images are captured at 2500dpi and are made instantly accessible through the ICON integrated networking platform.

Schober

Schobertechnologies launches high-speed-robot technology for stacking and counting long and very challenging/complex IML-products inline with its RSM rotary cutting machine.

The unit features rapid acceleration, velocity and precision in stacking very long IML products at continuous web speeds up to 50 m/min.

Exchangeable product-specific Pick-and Place fixtures allow for flexibility and rapid changeover and ensure that products of different styles and forms are reliably stacked nonstop in dual piling cassettes at synchronized speeds. An inspection system for 100 percent quality verification with integrated waste separation is also available.

The standard configuration of the IML rotary cutter includes an M-Stack delivery system. S-Stack or the high-speed robot ‘Spider’ deliveries are available as options for future upgrades.

Additional optional equipment are an adjustable de-nesting station for several products across, offering reliable product stacking even for off-set product orientation as well as an antistatic device and a gap control system (GCS) for precise wear compensation of the die. Additional technologies to be highlighted at the show include die cutting, laser cutting, sealing/embossing, punching, cut & place, scoring/grooving, gluing/bonding, cutting, collating and product delivery.

Soma

Soma’s new Venus III slitter rewinder is designed to convert film materials in web widths from 1100mm to 1850mm and has an overhead web path to enhance clean room conditions and permit entry into the food and pharmaceutical packaging markets. The company’s new PLUTO llI slitter rewinder, meanwhile, has stronger side frames permitting accurate slitting at speeds up to 600m/min in widths from 1100 to 1600.

Stork Prints

Stork Prints shows its established DSI UV inkjet press with a new digital primer, enabling printing on machine coated paper. The press is supplied with four print heads as standard, but an additional six can be added to enable options like the digital primer, digital white and an extended color gamut through orange and violet.

The company also launches a new range of light-weighted gravure sleeves and adapters. The reengineered sleeves are based on a single metal technology – directly engraveable nickel.

As well as standard electromechanical engraving, the nickel sleeves can be engraved by Stork Prints’ direct laser engraving systems for a fully digital, one-step process. This eliminates the cost of film and time-consuming exposure, washing and drying processes. No chrome plating is needed, which saves handling and is more environmentally friendly. After usage, the sleeve can be scrapped and the nickel re-used for new sleeve production. The sleeves weigh just 20 pounds and are available in any repeat size from 12” to 42” and in printing widths up to 75”.

The program is completed with Stork Prints’ adapters, the bridge between mandrel and sleeve. Sleeves can be mounted in and outside the machine, potentially reducing set-up times dramatically.

Tresu

Tresu Group will unveil an inline, pressure-controlled varnishing system for high-speed, sheet-fed and web offset printing presses. Suitable for UV- and water-based varnishes, and based on Tresu’s ancillary´s flexo technology, the new self-regulating system comprises the Tresu UniPrint Combi chamber doctor blade E-line and Coating Circulator and a Tresu Coating Conditioner.

A key feature of the concept is the company’s Pressure Control Technology. This ensures a sufficient pressure so that a constant barrier is maintained between the chamber doctor blade and the rotating open anilox cells, preventing air-bubbles from entering. Working with the UniPrint Combi is the Tresu Coating Circulator i Series. The circulator automatically adjusts to the coating supply and initiates either a six-minute or intensive 12-minute cleaning program, enabling fast job changes. By means of a sensor to measure coating volumes and press speeds at the doctor blade, the circulator regulates coating consumption. Temperature regulation for UV coatings is achieved with Tresu’s new Coating Conditioners, which feature an automatic re-filling system to maintain coating quantity and temperatures of up to 55ºC.

Vetaphone

Vetaphone will demonstrate its updated VE1C Station with the unique Quick Change System enabling quick and easy cleaning and changing of the complete set of electrodes, in a matter of seconds, without the use of tools, and ensuring minimal downtime and increased productivity.

The open type of Corona-Plus treater station has an easily accessible design for single or double sided treatment. The stations can be fitted with a wide range of ceramic and metallic electrodes in a variety of shapes. The treater stations give optimum surface adhesion on all types of plastic, paper and metal substrates.

The electrode cartridge is available with segment-, profile- and ceramic electrodes. The Quick Change (QC) electrode cartridge is aimed at film lines with widths from 100 mm to up to 2500 mm. Vetaphone will also display the new iCorona generator series with features including auto power density control, auto quality reports and auto maintenance schedules all controlled via an intuitive touch control panel.

Will/Pemco/Kugler-Womako

E.C.H. Will, Pemco and Kugler-Womako will focus on converting digital print in the book and bindery space. Pemco also shows the SHM Digicut, a highly flexible precision sheeter for digital, cut-size and folio-size formats. The SHM Digicut processes all types of material from digital printing paper, coated paper and board up to film. Flexible working widths as well as fast changeover times allow for the efficient production of small volumes too, says the group.

Weifang Donghang

Chinese press manufacturer Weifang Donghang is launching three new presses in Europe as it sets up a European distribution and technical support network and opens a major new manufacturing facility in China.

The intermittent offset press first seen at Labelexpo Asia in Shanghai last year (see L&L 1 p46) is constructed to be sold in global markets, using Rexroth servo motors throughout, automated registration control and a BST inspection system. The company also launches a new flexo press and a digital press using Xaar inkjet heads.

X-Rite Pantone

X-Rite and its wholly-owned subsidiary Pantone will showcase Pantoneive, a cloud-based service to obtain consistent and accurate color for packaging from design to the retail shelves. It applies to standardized and automated workflows applied to multiple packs involving a variety of substrate types. PantoneLive covers all stakeholders, from brand owners and designers through to pressroom operators. Enhanced Pantone color libraries are also featured.

Also new is X-Rite Pantone’s i1Pro 2 color management system. The redesigned i1Pro 2 hand held spectrophotometer is combined with the new i1Profiler software v1.3. It incorporates the latest touch-and-swipe navigation technology and intuitive software to allow operators to make quick and easy color measurements based on the latest ISO standards. The i1Pro 2 platforms include the X-Rite Graphic Arts Standard (XRGA). This makes it quicker and easier for companies involved in digital printing to adhere to ISO standards and achieve reliable and repeatable CMYK and spot colors.

Zeller+Gmelin

From Zeller+Gmelin comes a new UV offset ink, Uvalux U70 designed to give good adhesion on non-absorbent substrates like metalized film or board. Z+G says the ink has high color strength, good ink flow – also in chamber systems – high reactivity and low odor. Two other inks from the Uvalux series will be promoted: Uvalux U40 offset and letterpress inks for universal use on paper, board and synthetics, and Uvalux U40 series for direct mail printing.

Z+G will also show its full range of low migration UV printing inks for food packaging, including Uvaflex Y71 UV-flexo inks formulated for printing labels on paper and synthetic substrates, unsupported film, folding cartons and flexible packaging. The ink is claimed to show improved wet-rub resistance on synthetic substrates. Other low migration UV inks include Uvalux U41 – the low migration alternative to the Uvalux U40 series for offset and letterpress and with equal press performance and adhesion properties. Uvalux U71 is the low migration alternative to the Uvalux U70 series.

Other companies exhbiting include: Atlantic Zeiser, Durst, EFI, Flint, Flexo Concepts, GMG, Impression Technology, KBA, Landa, Nip Control and Recyl. Dscoop will also be present, click here to learn more about its activities at the show.

Pictured: EskoArtwork’s CDI Spark 4835 Auto

This article was published in L&L issue 2, 2012

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.