Sato introduces single-source coding and marking offer

Sato has introduced a single-source offering featuring printed labels and laser hardware for the product coding and marking sector, based on DataLase technology.

DataLase is an in-line digital printing company. Headquartered in Cheshire, UK, it works with a selection of strategic partners across inks and coatings, substrates and brands to deliver in-line digital printing of products and packaging.

Having previously acquired DataLase, Sato laser technology and labels have now been optimized to work together, enabling the coding of variable data, such as expiry dates, lot numbers and alphanumeric text, on to all types of primary packaging labels.

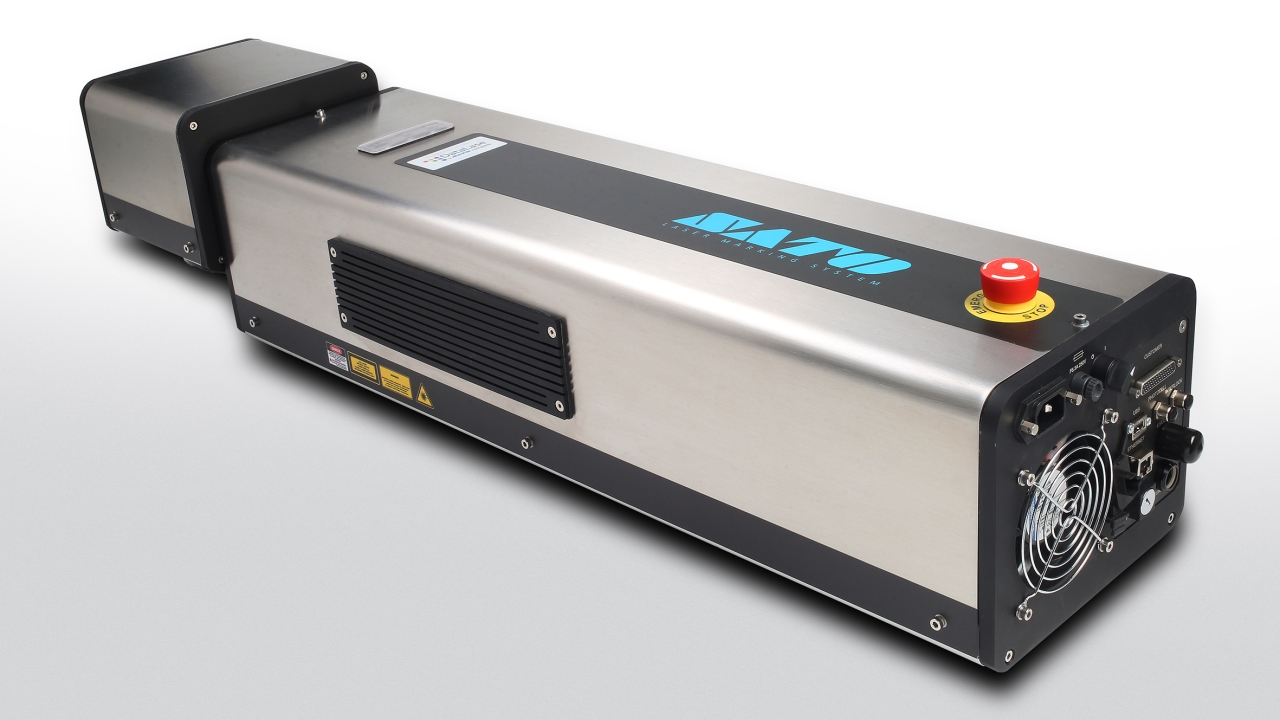

The next-generation offer includes printed UV flexo labelstock complete with a laser reactive patch incorporating DataLase color-change technology. With installation of a Sato product coding carbon dioxide laser at the fulfilment stage, brands and retailers can implement high quality, high contrast, permanent black-on-white coding of primary labels and packaging suitable for a wide range of markets.

The new total technology offer is being initially rolled out in the UK and Singapore in the first half of 2018, with further global expansion into Europe and Asia expected over the coming year.

Mark Naples, chief sales and marketing officer at DataLase, said: ‘Modern production environments demand robust, high contrast expiry dates and lot numbers to ensure compliance and traceability of products and packaging. Meeting these challenges can prove difficult with many of the existing coding and marking methods falling short of expected standards, especially when it comes to high servicing and maintenance costs and the need to continually order, stock and replenish expensive – and sometimes hazardous – consumables.

‘We believe by DataLase and Sato working together as one reliable partner to the industry, we can meet these benchmarks through our complete laser and label solution, improving operational efficiency and reducing unnecessary waste in the supply chain.’

Naples continued: ‘Both Sato and DataLase are committed to offering competitive product coding solutions that eliminate consumables from production environments and improve overall production efficiency. Having a single point of contact for all labeling and coding requirements will help to streamline supply chains and ultimately reduce costs.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.