Chinese flexo plate trade shop invests in Flint nyloflex NExT exposure unit

Chinese flexo plate trade shop Sinwa has invested in a nyloflex NExT exposure unit from Flint Group in order to increase the quality of its output, improve its efficiency and offer added value to customers.

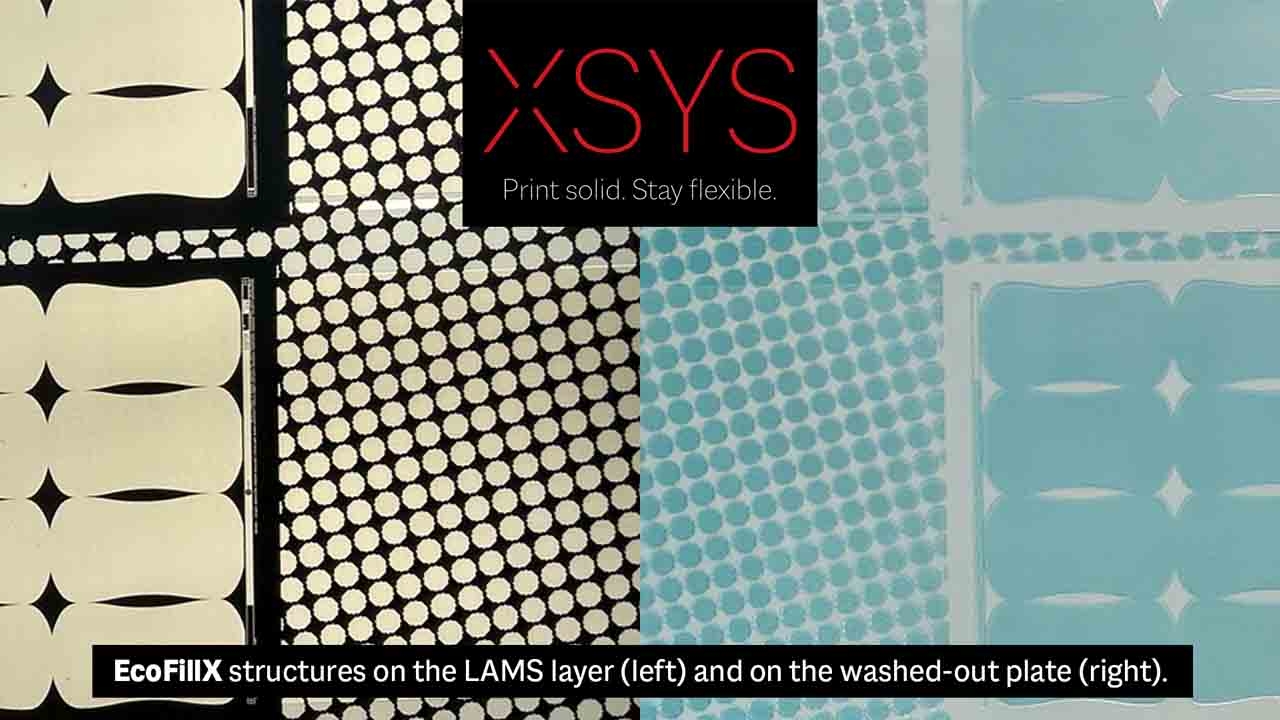

The nyloflex NExT exposure technology uses a high intensity UV-A LED light source to conduct rapid cross-linking of the photopolymer surface. The high UV-A output results in a virtual 1:1 image reproduction from the digital file to the finished plate. Flint Group said that in flexible packaging, printing plates exposed with this technology allow excellent ink transfer, particularly in solids, due to the option to precisely reproduce surface screening structures. And in corrugated printing, fluting is reduced.

Michael Lin, managing director of Sinwa, said: ‘We can completely rely on the nyloflex NExT exposure technology, which has been proven to be the easiest and most consistent way for the flat top dot application; meanwhile it enhances our competence and further differentiates us.’

‘We are very proud that such an innovative company like Sinwa has decided to go with our system,’ added QiHong-Magenta Zheng, general manager Flint Group Flexographic Products in China.

Sinwa has also chosen to invest in a nyloprint Combination CW 50 x 70 compact letterpress platemaking system from Flint Group as it looks to expand its business into letterpress label printing.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.