Tresu iCoat 30000 coater supports Digilinck's HP Indigo 30000 investment

Belgium-based printer Digilinck has installed a Tresu iCoat 30000 coater as part of its investment in single-pass digital folding carton production.

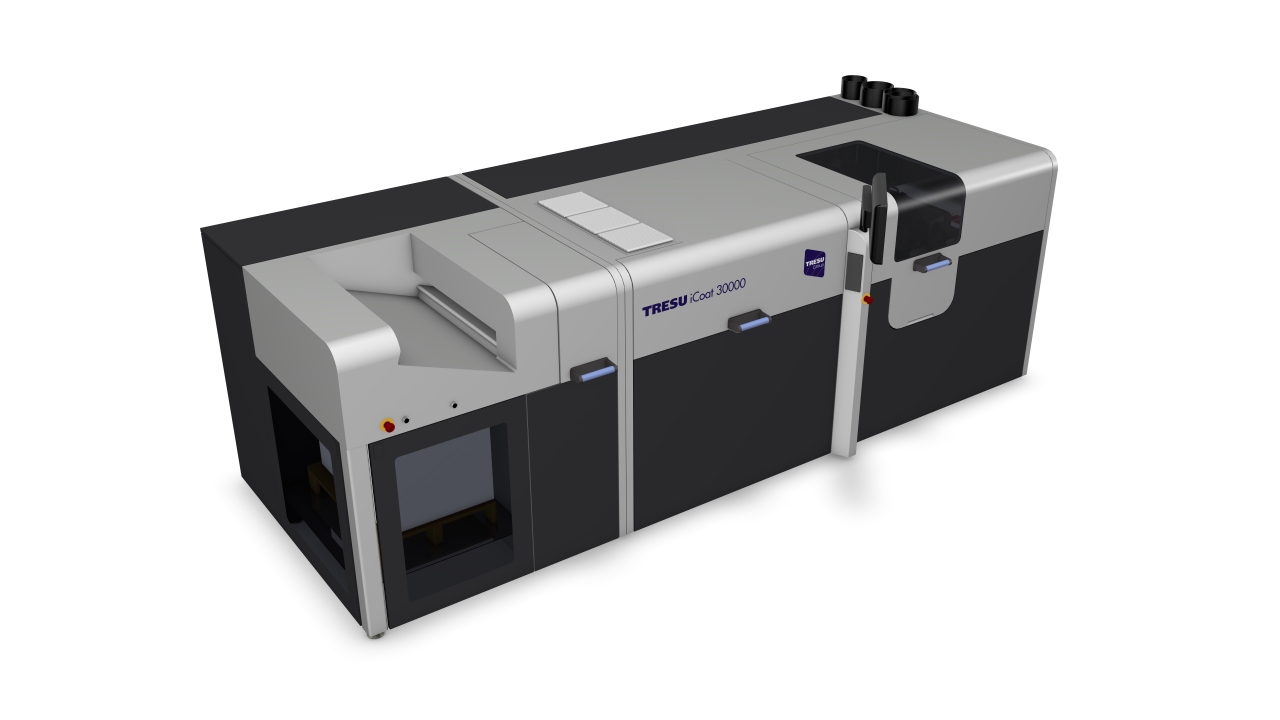

Digilinck has installed an HP Indigo 30000 digital press with integrated Tresu iCoat 30000 coater, in order to meet growing demand for digitally printed folding carton packaging. iCoat 30000 is a flexo coating unit that can apply water-based or UV varnishes directly after the digital printing stage, both to provide protection to the underlying graphics and to enhance aesthetic appeal.

An exclusively digital printing business, Digilinck has expanded rapidly since it was established in 2011. Now with a workforce of 25, the company supplies luxury packaging and self-adhesive labels to retail goods and pharmaceutical markets in Northern Europe. Digilinck attributes its fast growth to its two existing HP Indigo WS6600 digital presses, which enabled the company to supply short runs and provide a host of added value services, like variable data and personalized products. Its success in meeting the client base’s needs with fast turnarounds attracted significant new business, and in 2014 the company supplied in excess of 12000 orders.

Its investment in an HP Indigo 30000 sheet-fed digital press, the first in the Benelux countries at the time, was confirmed at the end of 2015, and reported here. The 7-color digital press, integrated with the Tresu iCoat 30000, provides a seamless single-pass printing and coating line for folding cartons, with minimal logistics or material waste. The line runs at 3450 B2-size sheets per hour, with a maximum of 4600 sheets per hour. This enables the company to print jobs in excess of 30,000 units in approximately two hours. However, both machines are capable of reaching 5000 sheets per hour on board substrates of maximum format 750 x 550mm.

Vincent Oosterlinck, owner and founder of Digilinck, commented: ‘The crucial factor in our success at Digilinck has been our ability to offer fast lead times, and exploit the full potential of the digital process. However, the growth we experienced made it challenging to meet commitments, even when both machines were running three shifts a day. We needed to invest in a new press urgently.

‘The HP Indigo 30000 together with the Tresu iCoat 30000, was the ideal complement to our HP Indigo WS6600 digital presses. It delivers the identical quality cost-efficiently, yet with twice the productivity. This gives us the ability to grow and maintain the flexibility on which our competitive edge depends.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.