FFEI to launch new inkjet press

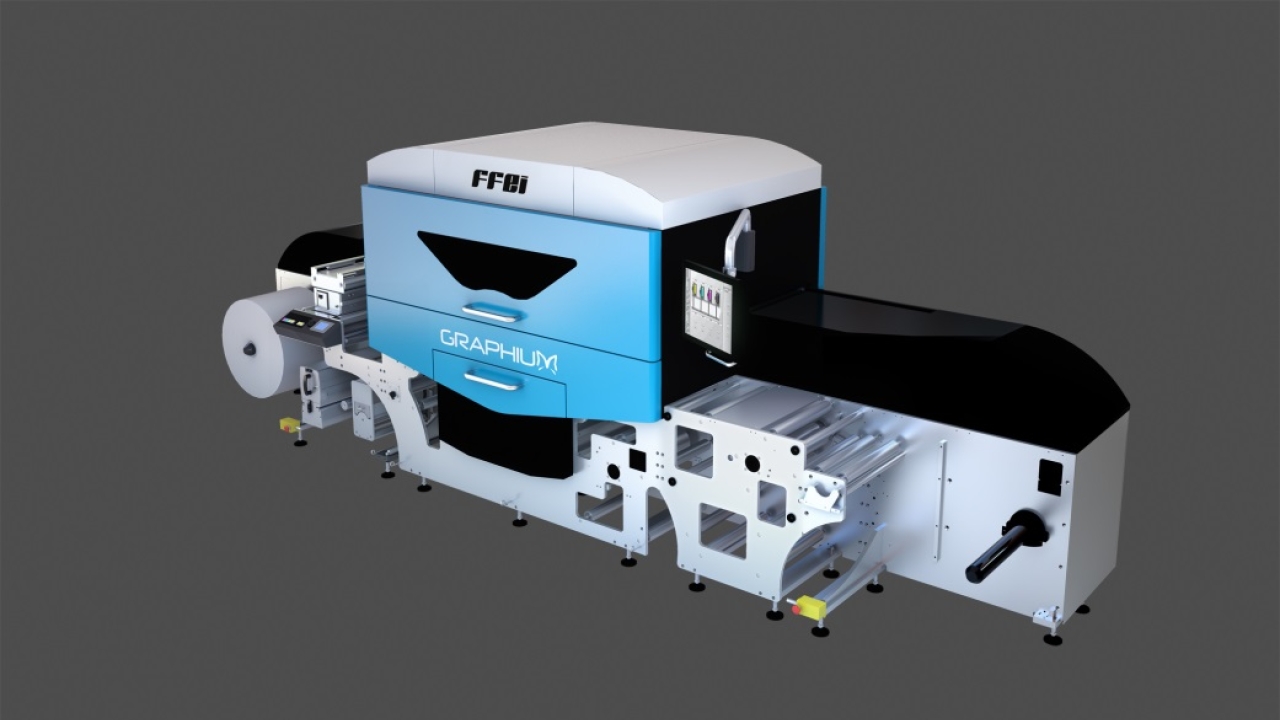

FFEI is to launch Graphium, a new modular digital UV inkjet press with high opacity digital white for the production of labels, packaging and specialty print.

Graphium combines workflow, pre-press, color management software and head calibration technology to ensure consistent quality through repeatable production.

FFEI said that Graphium combines a range of technologies that allow users to convert complex jobs that are not economically viable with standalone conventional or inkjet presses.

Graphium also uses specialist Uvijet Graphium UV curing inks developed by Fujifilm Speciality Ink Systems, which combine the functional performance, color gamut and adhesion needed for label printing with reliable jetting performance required for consistent printing.

FFEI has worked closely with the Xaar research and development team to ensure Graphium maximizes the full capability of the Xaar 1001 printhead technology. The press further features corona pre-treatment, web cleaning, inter-color pinning and Adaptive Screening Technology.

Graphium will be on show at Labelexpo Europe 2013 and Print13, both taking place this September.

Andy Cook, FFEI managing director, said: ‘We are on a mission to transform the digital labels, packaging and specialty print market, and Graphium represents a major step towards achieving this goal.

‘Graphium represents a new generation of digital inkjet press aimed at the narrow web market – low capital investment, high-quality print, unparalleled productivity and the most versatile range of applications. Bring all of these factors together and you have a cost-in-use that defines Graphium as the most productive, high opacity digital white press on the market.’

He added: ‘When developing this press, we wanted to bring our many years of software and inkjet expertise together to create a complete solution that transforms the print process. With Graphium, converters can now achieve greater efficiency from pre-press to production and benefit from reduced start-up costs, minimal waste and increased productivity. The return on investment over conventional printing is huge – not only for short-runs, but longer also.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.