FFEI to update Graphium

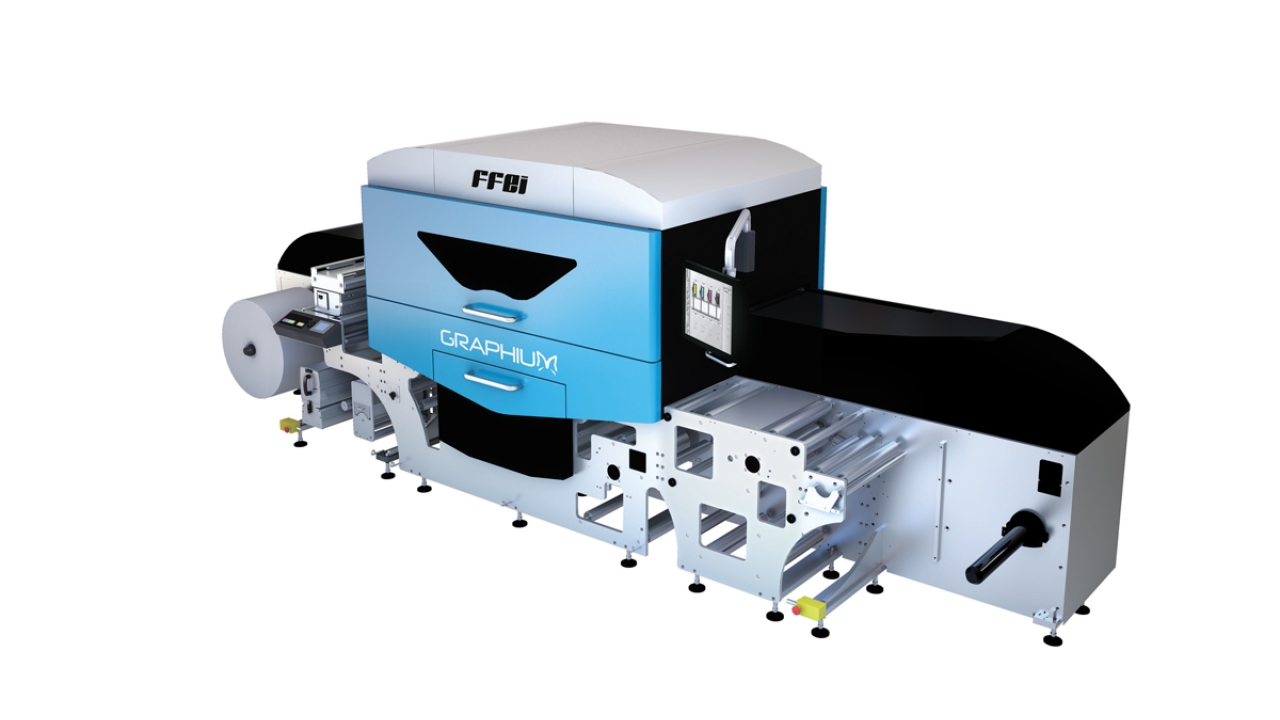

A range of new features including over white and sync-to-mark will be demonstrated on a fully featured hybrid Graphium configuration at Labelexp Americas 2014.

A Graphium press will feature on the Fujifilm stand, and will include pre- and post-digital flexo stations, a cold foiling station and die-cutting unit.

FFEI said the over white capability is set to further extend the different applications a digital UV inkjet press can be used for, as adding an over white print capability not only increases the overall flexibility of what can be produced but also dramatically increases the potential opacity when used with the Graphium under white.

The use of over white can also significantly enhance text. For example when a colored background with white knockout text is required it often suffers a lack of clarity. In these cases small text in an opaque white may be overprinted or a combination of a knockout with overprinted white used to clean-up and provide clarity. Additionally over white provides enhanced definition and clarity and brings the highest levels of flatness in pure white areas of a label. This is achieved by printing a second white as a mask of the visual effect of the under white.

This new, unique capability provides converters with a host of additional ways to enhance the overall look and feel of their labels.

Andy Cook, FFEI’s managing director, said: ‘Graphium already boasts a high opacity, high adhesion under white, which is critical when looking to achieve a number of design finishes and boost color vibrancy.

‘Having the ability to print a second high opacity white as a final digital color has several benefits for a variety of applications; from decals to window stickers.’

In addition to the over white, FFEI is launching a number of additional enhancements including the capability to now support substrates of 40-600 microns allowing the thinnest liners to heavy duty vinyl to be used. Furthermore to ensure clients’ quality expectations can be easily defined and their color requirements met regardless of when the job is reprinted, Graphium is capable of printing to an ISO 12647-2:2204 standard.

Cook added: ‘Graphium was designed to handle a range of label projects regardless of complexity or application and produce labels that are fit-for-purpose in a number of different environments. Now supporting under and over white, along with and six flexo stations, Graphium offers unique “concept to finished product” capabilities – converters are able to integrate optional flexo and finishing stations inline, not just for conversion in a single pass, but also to maximise their reach into new market sectors.

‘Graphium can include everything a standard press can, it is completely modular with die-cutting, sheeting, slitting, cold foil, laminating and UV or aqueous flexo units. This ensures converters can, not only produce labels in the leanest possible way, but also that they can handle many more varieties of label applications on a digital press.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.