KBA and montex-print strike die-cutter deal

German press manufacturer Koenig & Bauer (KBA) has entered into a partnership with montex-print to develop, manufacture and market new, high-performance sheet-fed rotary die-cutters.

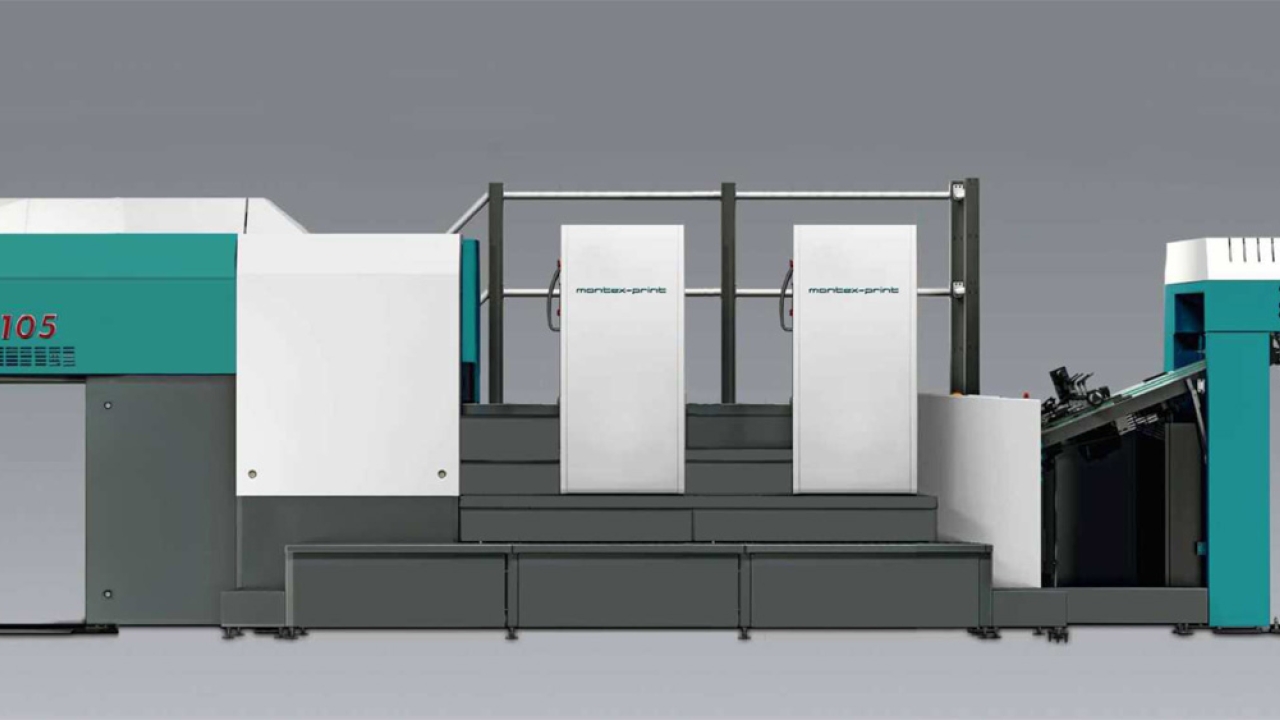

Under the product name DC-R 105, montex-print will distribute single- and double-unit rotary die-cutters based on the technical platform of the medium format sheet-fed press KBA Rapida 105.

The DC-R 105 is designed for sheet formats from 360 x 520mm to 740 x 1,050mm, and has a maximum production speed of 12,000sph. It can handle substrate from 0.03mm to 0.7mm. Set-up is operated from a control panel at the delivery, as the console normally installed with an offset press is not necessary for a pure die-cutting machine.

In a double-unit configuration, the DC-R 105 features two magnetic cylinders for combination jobs, such as creasing, kiss cutting and perforating or with a special folding carton module in the first unit and regular die-cutting in the second.

The growing market for in-mold labels is also highlighted as a target for the DC-R 105.

Upon receipt of an order from montex-print, KBA will supply all the modules required for a sheet-fed rotary die-cutter, including feeder, in-feed and die-cutting unit, together with the associated drive systems, electrical equipment and air supply, as a ready-assembled machine. This will also feature montex-print's magnetic cylinders in the die-cutting unit.

Transport, installation, commissioning, training and customer service are to be handled by montex-print.

Montex-print has been repairing and overhauling used printing presses since 1978, and has established a reputation for the conversion of used sheet-fed offset presses into rotary die-cutters. With the development of a new rotary die-cutter together with KBA, montex-print is now taking its next steps while maintaining its used press business.

The first DC-R 105 is expected to be ready for demonstrations at KBA in Radebeul at the end of May, with the first deliveries from early autumn.

Eberhard Fuchs, managing director of montex-print, said: ‘For all those customers who seek to generate additional revenue with flexible finishing of the most varied materials, formats and run lengths, we offer the best price-performance ratio thanks to the simple handling and extremely fast make-ready.

‘That applies, for example, to the fast-growing IML segment, but at the same time also for short-run packaging, self-adhesive labels and other special materials. The DC-R 105 is the perfect machine for such jobs.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.