Universal Converting Equipment completes latest expansion phase

Universal Converting Equipment has completed the latest phase in its expansion program designed to support a doubling of its turnover in the last two years.

Phase one of the expansion included creating additional manufacturing space, and hiring more designers and assembly staff.

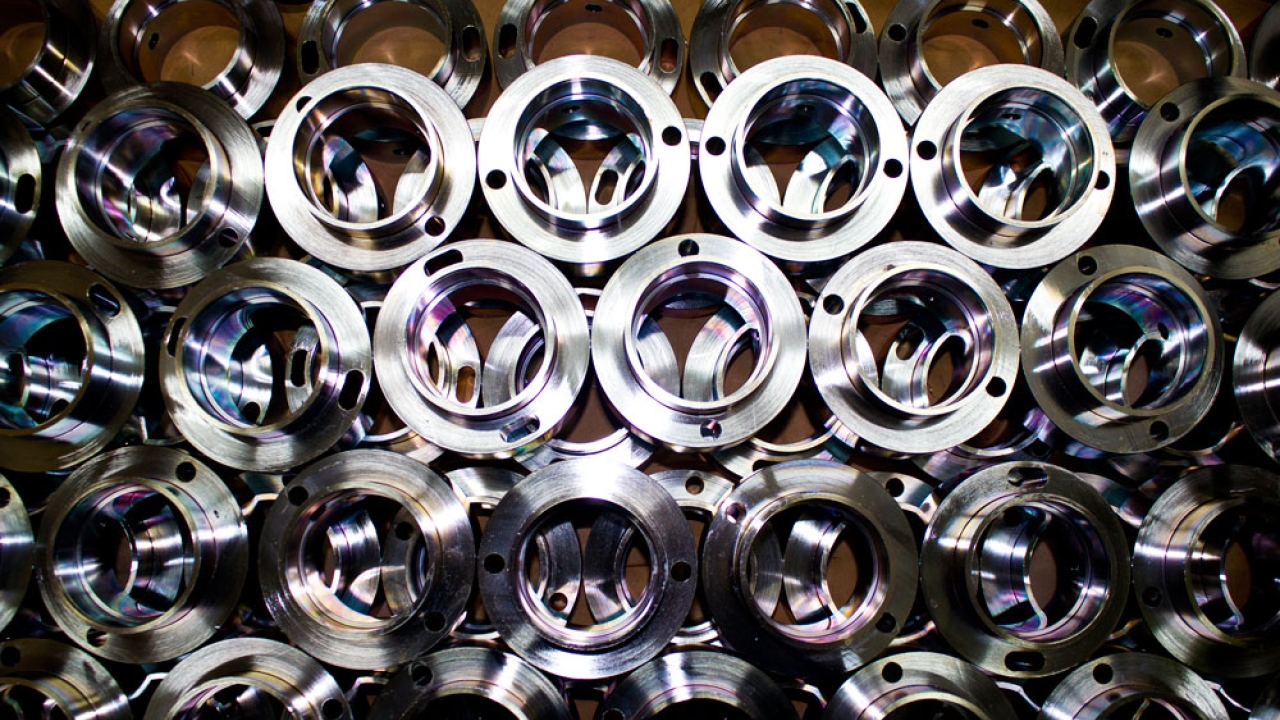

Phase two has seen Universal Converting Equipment install its own machine shop in order to become self-sufficient in regard to production of machined mechanical parts. The company said this was in response to a lack of capacity at its sub-contractors to meet its increased demands.

Phase two has now been completed following the installation of one million GBP (1.6 million USD) of CNC-controlled machine tools, including a CNC mill for the manufacture of machine side-frames, a CNC lathe for production of rollers, PC-controlled roller balancing equipment and a range of CNC machining centers for the manufacture of other parts.

Special foundations were built for some of the equipment. For example, the large mill sits on a solid reinforced concrete base over 1,000mm deep. Levelling the machine bed to the tolerances required took a specialist team over a week to achieve.

Alan Jones, Universal Converting Equipment managing director, said: ‘We have been using 3D CAD systems to design our machines for the last 10 years. We have now invested in CAM software systems so that the part drawings can be converted into files that can be downloaded directly into the CNC machine tools. This prevents errors caused with manually controlled machines and eliminates data entry mistakes. The CAM system ensures we have consistently high quality components with the minimum of downtime when new designs are entered.

‘Since installing this equipment, we have changed the design of some components so that the machining time can be reduced resulting in cost savings that can be passed onto our customers. We have used our own resources to fund this investment without the need for borrowings, increasing the financial strength and stability of the company. We are now commencing phase three to increase our global sales and support infrastructure.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.