Erhardt+Leimer launches new web guider

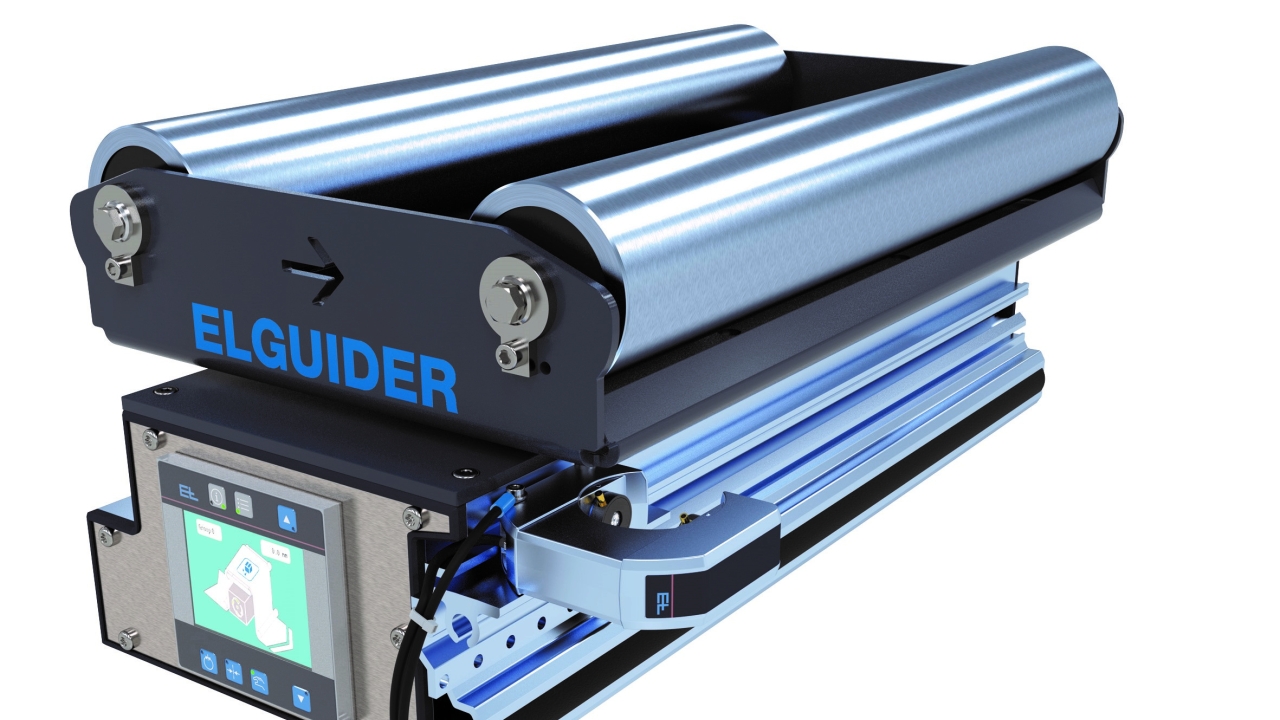

At Labelexpo Europe 2017, Erhardt+Leimer has presented a cross-section of its wide range of products for the label industry. On show for the first time is a new web guider and a new web tension measuring amplifier.

The new DR 2301 web guider from the ELGuider product family was developed especially for the label industry. The key parameters are already pre-set on delivery, and a commissioning wizard guides the operator step-by-step through the additional input windows that need to be filled in. The unit is operated via a touch display (RT 4008). The installation situation is visualized for the customer on this display in exactly the same way as it presents itself to the operator on the actual machine.

The compact web guider has an integrated absolute value encoder, meaning reference runs are no longer required, and which also ensures that the current position is saved in the event of a power failure. The motor used in the actuating drive is brushless and thus wear-free. The use of roller bearings instead of slide bearings effectively prevents stick-slip. The new unit also impresses in terms of control dynamics, with a control frequency of up to 8 Hz.

In addition to infrared sensors and ultrasonic sensors, the color line sensor FE 52 can also be used for web guiding. This sensor has a trigger mode, which means that there is no need for a continuous guiding criterion on the web.

As an option it is also possible to integrate a splice table with an adhesive roll and pneumatic web clamps.

Web tension displayed separately for left and right side

The PA 62 is a two-channel measuring amplifier for connecting any load cells; it displays not only the sum signal but also the web tension on the left and right hand side of the web separately. The device can do without any fixed buttons; buttons for operation are displayed on the LCD display only when required. Besides the actual web tension it indicates a trend curve and alerts the operator if limits are exceeded. The inputs and outputs can be configured individually. The device also offers an Ethernet interface for process integration.

Simple and inexpensive quality assurance

The Smartscan system offers simple and inexpensive access to print image monitoring. But more than this, in fact the system is a genuine multi-talent: in addition to a video function with zoom, it also enables 100 percent print image inspection, splice detection and detection of missing labels and unremoved matrix. You can pick and choose the different functions you require and combine them building block-style into the perfect system for your specific requirements.

Thanks to a special illumination concept for inspections, not only can the process of setting up jobs be almost fully automated, but it is also possible to set up reliable defect detection. The simplicity of the system means that during normal operation, the operator will usually only need to press one button after changing jobs in order to be able to start the inspection.

Since the camera unit is housed in a compact enclosure, Smartscan can be retrofitted to existing printing machines and finishing machines.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.