Gerhardt expands 7* rotary die range

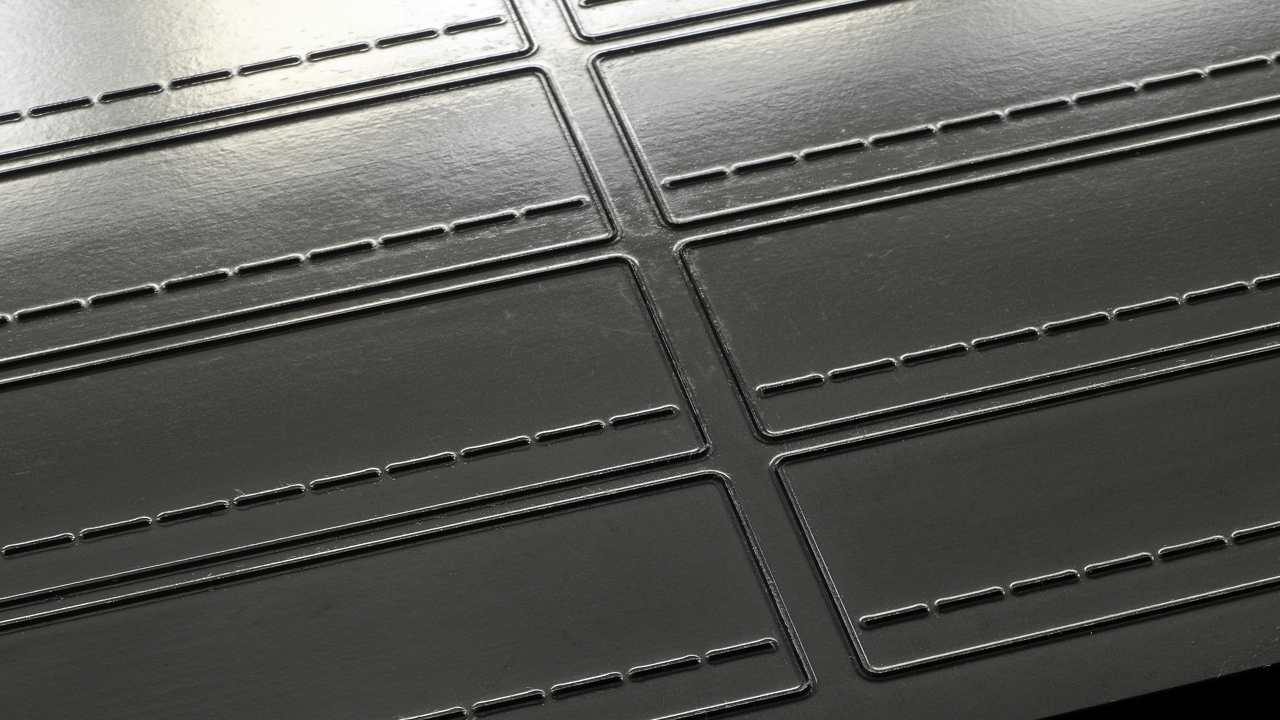

Gerhardt has expanded its 7* (star) rotary die range. Thanks to a new long life coating, a 7* flexible die has been added to the range for the first time. The existing 7* solid rotary die has an extended lifetime.

The 7* flexible die has a long life, wear-resistant coating that has a low coefficient of friction property. The coating’s wear resistant properties are used in the aerospace industry and on surgical implants such as hip replacement joints. It is suitable for converting abrasive materials such as thermal transfer, materials with an aggressive or fluid adhesive, labels being printed with abrasive inks/coatings and for anyone wanting to convert very long runs. Tests show ten times longer runs than with normal hardened EDM dies, reports Gerhardt.

The 7* solid die is made from powder alloy, especially designed for cutting in tough materials. The hardening process and annealing process is designed to give it a fully hardened and wear resistant performance. The steel is hardened up to HRC 64. The die is suited to difficult materials or long runs and can be repaired numerous times. It is reported to run up to three times longer than the previous 7* solid die.

Click here for more stories about Gerhardt on L&L.com.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.