Goss adds Contiweb for digital web presses

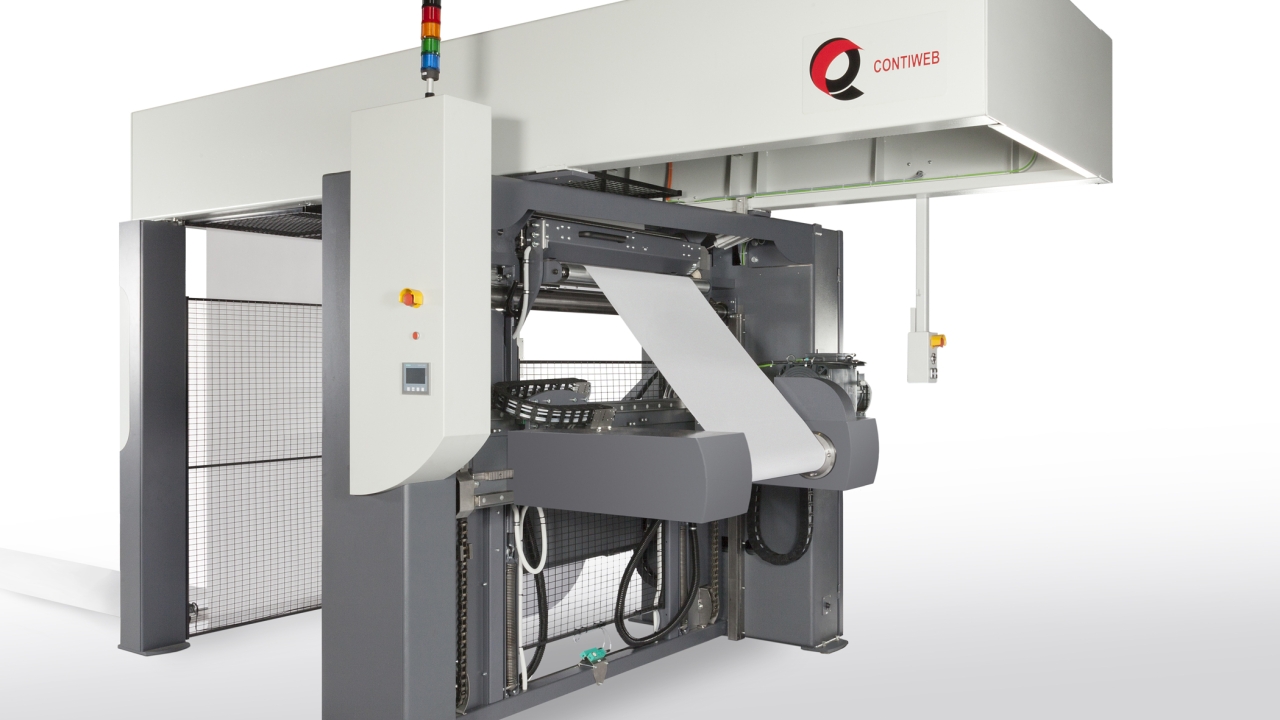

Goss has added six unwinder/splicers and rewinders developed specifically to address the requirements of digital web printing based on its existing Contiweb product line.

Available in two web widths, 770mm (30in) and 1100mm (42in), the CD range of splicer/unwinders and the CR range of rewinders share features that facilitate simple set-up, integration and day-to-day operation. These include floor-level loading and unloading of paper reels; unwinding/rewinding in either direction; as well as motorized reel side-lay adjustment; all of which can be monitored throughout via an HMI screen on the unit. Each model is shaftless and uses pneumatically expanding core chucks driven by low-noise electric motors.

CD models include: the CD-W unwinder with manual, stationary splicing; CD-S stop/go double unwinder with semi-automatic splice; and the CD-N fully automatic splicer with non-stop reel changeover. The CD series has been engineered to ensure accuracy and repeatability at every stage of the digital web in-feed process, regardless of operator experience or familiarity with web-fed production. The models come with a range of options including additional levels of in-feed control, web guidance, remote operation through the central control system and remote diagnosis via VPN.

The Goss Contiweb CR series of rewinders includes: the CR-W single rewinder; CR-S stop/go double rewinder with semi-automatic web transfer; and the CR-N non-stop unwinder with automatic reel changeover. The three versions can also be fitted with a slitter, and are available with optional extras such as integrated electronic web tension control at outfeed, web guides, central console operability and remote diagnostics.

Developed at the Goss Contiweb facility in the Netherlands, the new product lines have been designed to equal the Contiweb signature splice performance of 99.7 percent for digital webs. Available immediately, both the unwinder and the rewinder series are designed and engineered to be entirely modular, providing customers with an ‘easy path to full automation at either end of the press line’, Goss said.

The adaptable and modular design of the Contiweb digital series also expands their potential for use in labels and packaging applications. This is particularly in the case of customized Goss Vpak web offset press configurations incorporating a range of processes and ancillaries – such as flexo, gravure and digital stations, UV and EB drying – which would benefit from a higher level of tension control throughout the web path.

Read more about the overall web offset market for printing flexible materials, including the latest from Goss, in L&L issue 4, 2015, or here.

Bert Schoonderbeek, managing director at Goss Contiweb said the development recognizes the growth and potential in digital web printing. ‘After many years refining and perfecting product design to ensure efficiency and repeatable high quality for web offset printers, we’re now seeing a similar need within the digital web community. The increasing variety of installations and applications is creating a relentless demand from print service providers for technologies that advance their competitive edge. The ability to master web tension and to continually improve productivity is rapidly becoming critical to success.

‘Whether the customer is new to web-fed print production or an old hand, we feel very confident that with the CD and CR product lines we are equipping digital print providers with the very best technology to achieve maximum productivity and efficiency from their system. As the top production speeds achievable from digital web presses continue to rise, these capabilities will be of ever-increasing significance to the whole viability of the print operation,’ concluded Schoonderbeek.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.