New HMJ-250 ink dispenser launched at Labelexpo Americas

HMJ tech launched its HMJ-250 Medium Batch Dispenser at Labelexpo Americas 2016.

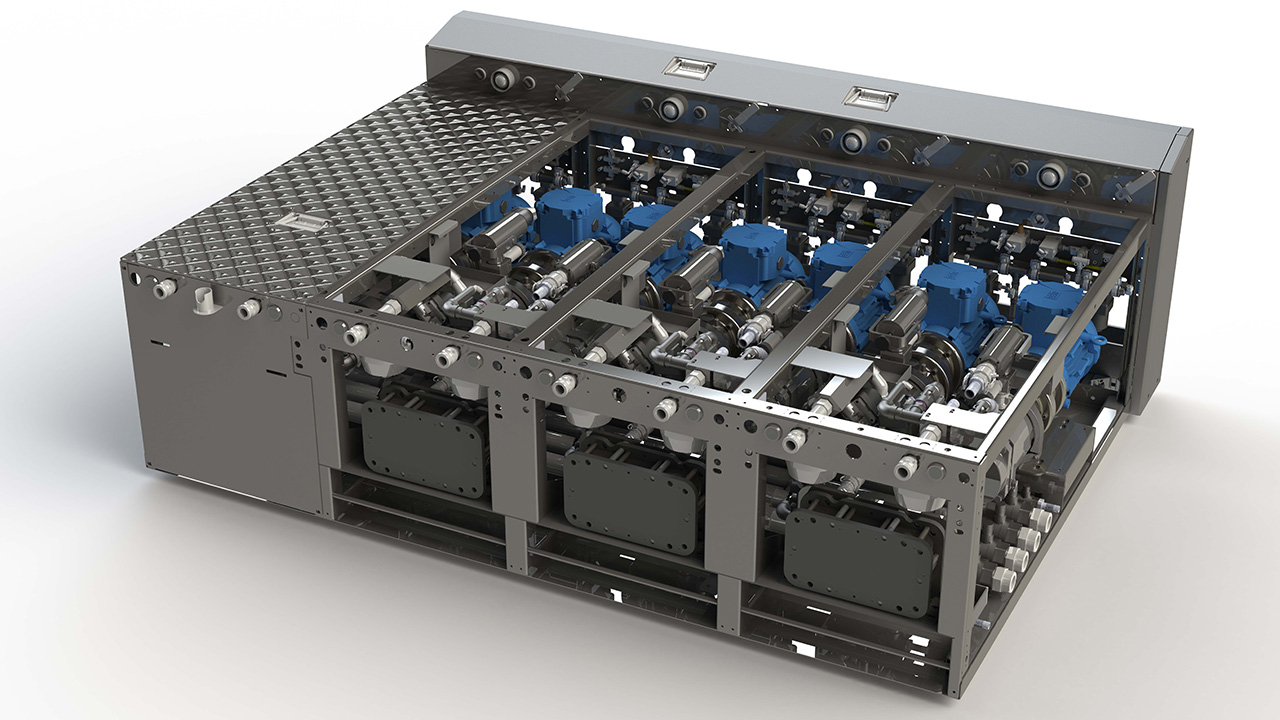

Making its debut in the INX International Ink Co booth, the HMJ-250 has a compact footprint with a stainless steel frame and rugged moving parts. Expandable to 24 stations, the versatile machine is capable of drawing from any type of source container including pails, drums and totes. It can quickly and accurately dispense into narrow mouth jugs, or pails up to six gallons.

As with all of HMJ tech’s automated dispensers, it includes a proprietary automated valve cleaning system that leaves the valves clean and dry after every dispense.

Hugh Chant, HMJ tech’s director of sales, said: ‘Our speed and precision specifications are impressive on paper, but people seemed really surprised when they actually see the dispenser run for the first time. They were impressed with how fast it can produce a batch of ink.’

‘Speed isn’t just about flow rate,’ he continued. ‘It’s about quick transitions, real time control and getting every batch within specification the first time. By taking an all-inclusive approach to our design philosophy, we can get ink to the press quickly and reliably every time. That’s what our clients care about.’

Chant said part of HMJ tech’s success stems from a focus on comprehensive media management solutions. ‘The dispense head is always the main discussion point but there’s more to it. Our modular media farm has dramatically simplified installations. It’s simple and easy to customize for ink rooms of all shapes and sizes. It can always be modified or expanded to grow with your printing operation.’

Also on display at the show was HMJ tech’s new Shadow Pail Mixer. Chant explained how this all-stainless, drip free machine can overcome the hazards of spinning shafts and impellers. ‘We took this project on to address industrial safety concerns. Open impellers present obvious risks, so we started with the OSHA and CSA guarding codes and we built a better mixer from the ground up. It has a ton of really clever features including offset mixing for better efficiency with lower aeration, and an integrated drip tray in the parked position to keep the mess off the floor. It’s 100 percent pneumatic and virtually maintenance free, a real showpiece that we are very proud of.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.