OneVision launches DigiLabel

German software manufacturer OneVision has introduced DigiLabel, a new software program for label printers designed to improve production processes, provide cost savings and enable a larger throughput.

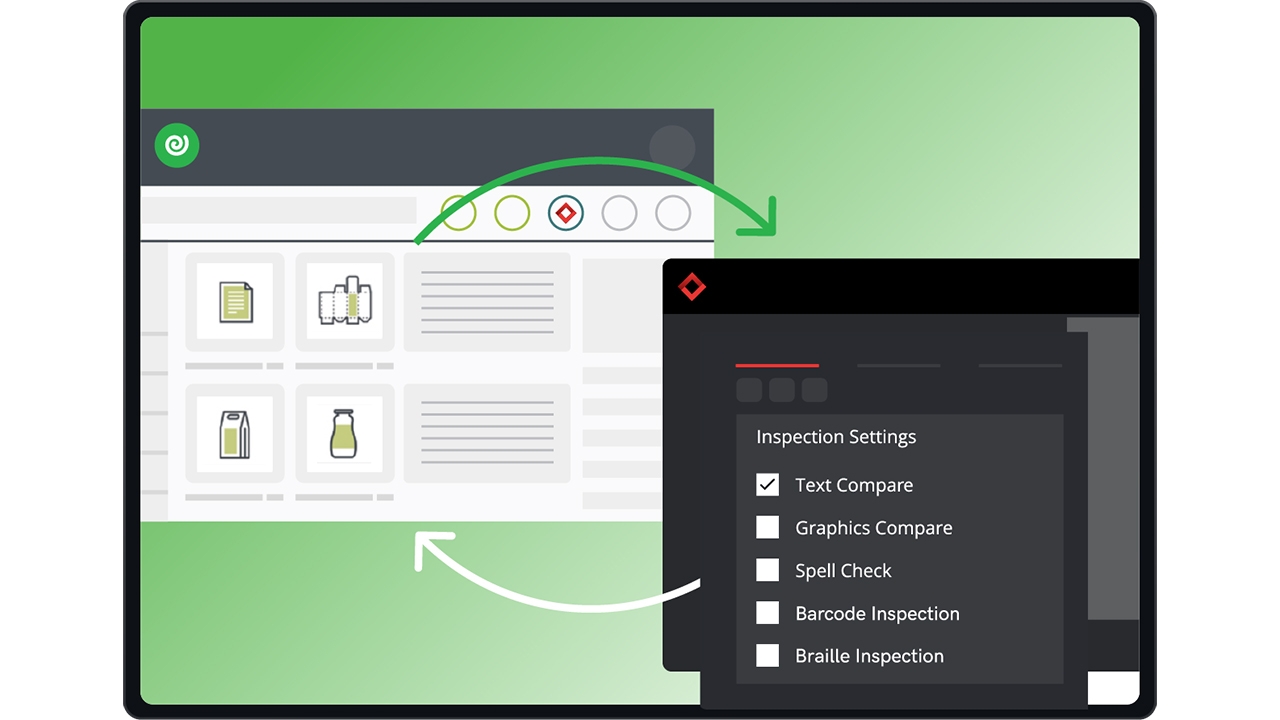

DigiLabel is a 2-in-1 system of automated label production, and is said to ease complex label workflows for digital label printers. It combines print data optimization and label production planning. DigiLabel imports production data and then automatically optimizes it. OneVision said the benefits of the system include improved transparency, a safe production process and significant improvements in efficiency.

OneVision is a known specialist in the commercial printing industry for pre-flighting and the normalization of print data for error-free printing. Its products include workflow tools that enable the entire production workflow to be integrated, standardized and substantially automated. It also covers quality control, and optimization of print files and images using RIP and Inksave software, as well as individual tools for the imposition of PDF files or flattening of transparencies, all done automatically.

OneVision is now bringing its expertise to label printing, with DigiLabel making use of this expertise in the entire production workflow: print data is automatically subjected to quality control and then optimized. The automated production of die-cutting molds or laser cutting configurations, standard cut lines, a white background and the automatic dispatch of a release PDF to the customer for approval saves labor time and staff resources. DigiLabel also assembles open orders and handles production planning.

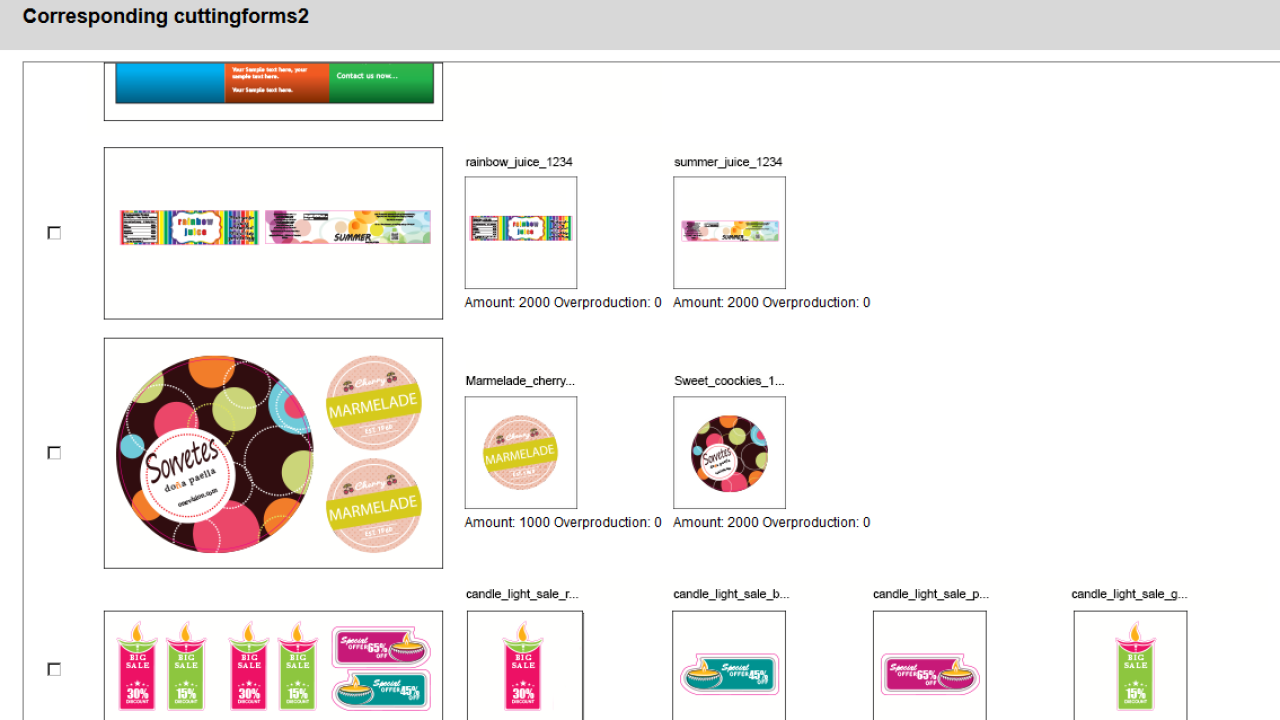

Fully automated, cross-customer collect-run production of labels using the new software is 'unique on the market,' according to OneVision. DigiLabel assembles open orders and combines labels of various shapes, sizes and print runs to be printed on the same substrate and forwards them to the printers. This reduces production error sources, lowers materials costs by saving on printing and also increases throughput, it is claimed.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.