RotoMetrics launches Challenger solid die for challenging abrasive applications

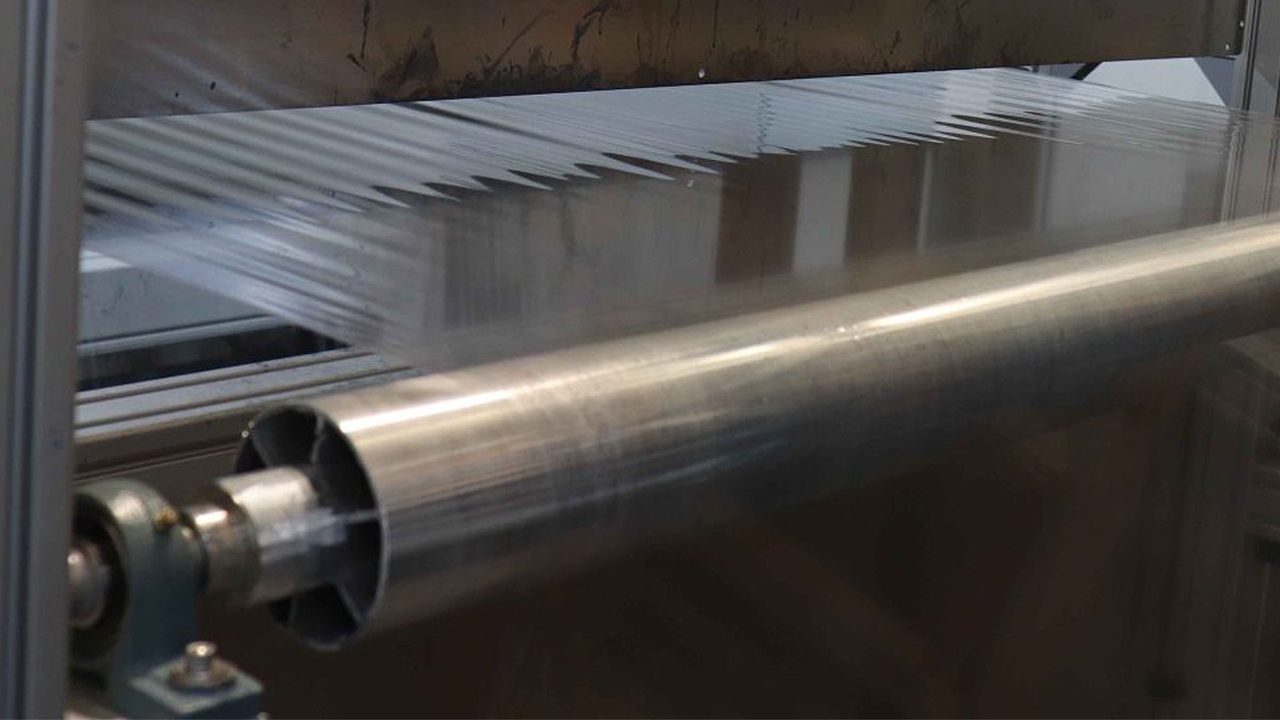

RotoMetrics has developed Challenger, a solid die designed for tough abrasive materials such as polylith, abrasive inks, credit/gift card stocks, clay-coated materials, recycled tags, thermal-coated materials and other challenging abrasive stocks.

Challenger’s enhanced tool steel, along with RotoMetrics’ proprietary TufShield plating, are claimed to improve performance over the traditional dies used in abrasive applications. Challenger solid dies run more than twice as long as typical chrome-coated dies, according to RotoMetrics. In addition, the Challenger’s blade wear is more consistent and uniform resulting in more retools.

Butch Schomber, product innovation manager at RotoMetrics, said: ‘We tested a variety of steel and coating processes to determine the best option to tackle these challenging abrasive materials. This unique combination of enhanced tool steel and our proprietary plating process produced a durable and tough solid die that not only lasts longer; it also creates more even blade wear.

‘Normally, these materials tear up blades and destroy dies, but Challenger’s unique combination gets the most out of a die and creates great value for our customers who convert these materials. Dies run longer on the press and last longer overall.’

The new Challenger die is currently available from RotoMetrics US manufacturing sites with global manufacturing expansion planned in the near future.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.