Xaar launches HL technology for textured effects

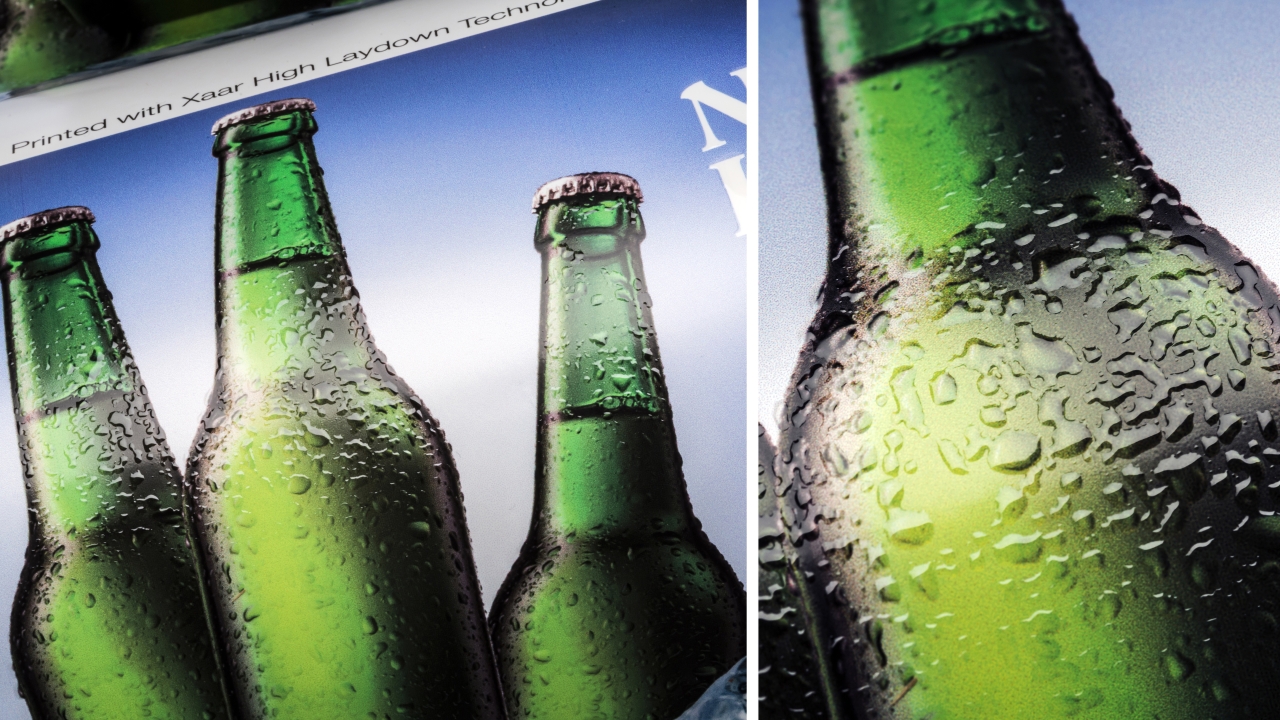

Xaar has developed High Laydown (HL), a technology for printing a range of textured effects on labels, folding cartons and products.

Xaar has also extended its Xaar 2001+ printhead family to include UV applications, such as printing labels and cartons. When incorporated into 2001+ and 1003 printheads, Xaar said HL can be used to print very high levels of UV clear varnish, even at high speed. The Xaar 1003 GS12U can print an 80 micron layer thickness at 25m/min line speed, or a 50 micron layer at 50m/min in a single pass, thereby building in texture as part of the print process.

HL extends Xaar’s range of deposition technologies, with a recent InfoTrends study reporting that print buyers are willing to pay up to 89 percent more for textured effects compared to standard CMYK-only work.

Xaar said such high build, textured effects – also called tactile or dimensional effects – can be used to significantly enhance the shelf appeal of products and ensure that they stand out when on display. The company added that HL brings adding textured effects ‘within reach for short and medium label runs’ when compared with using rotary screen, while it also compares favorably to other digital alternatives that use multiple print bars to build up sufficient layer thickness, or require machines to run at low speeds. Textured effects created with HL require a single print bar running at a reasonable production speed, Xaar claimed.

As well as adding texture as part of the print process, Xaar’s HL Technology can be used for producing raised foil effects for extra impact. Tactile information effects such as warning triangles required on hazardous products and Braille can also be created without the need for an additional print stage or process.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.