Xeikon launches web varnishing module

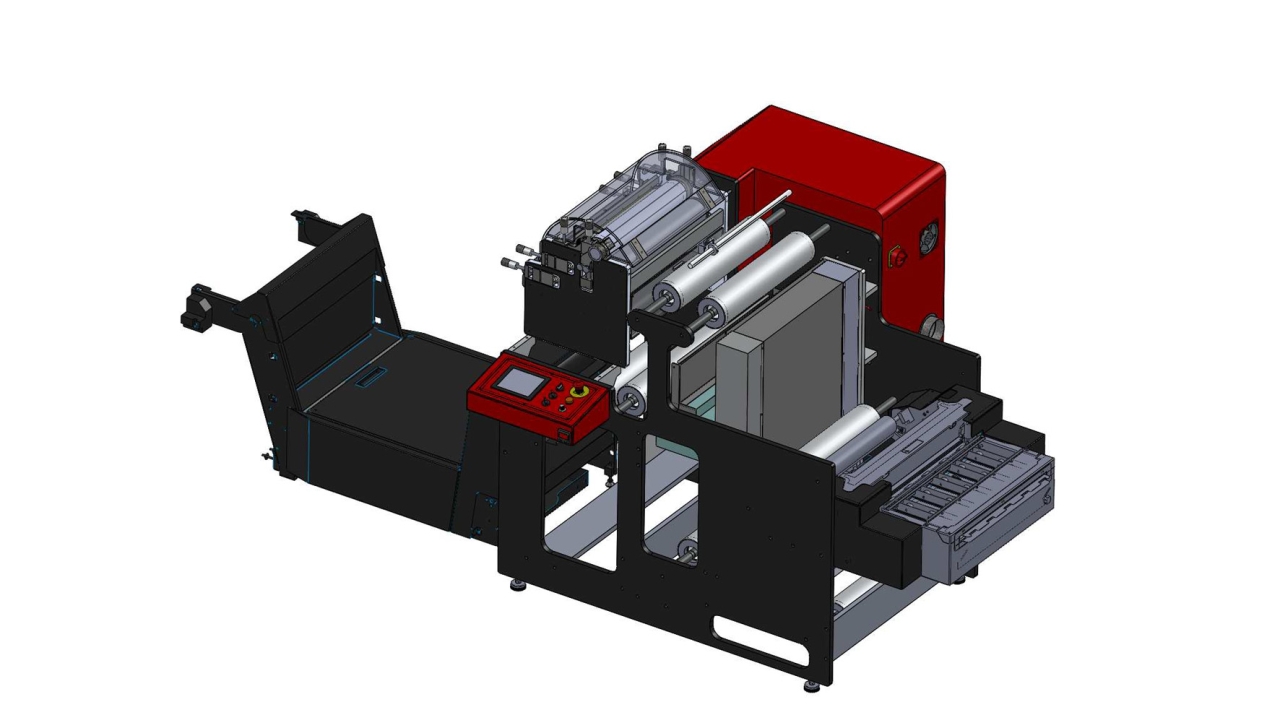

Xeikon has expanded the in-line finishing options available for its digital presses with the development of the web varnishing module, an extremely versatile unit that can apply UV or aqueous varnish on one side of a wide range of substrates.

The web varnishing module runs in-line with Xeikon 3000 presses, at full press speeds, and the print roller can be changed easily to match the repeat or width of the job being printed. In addition to applying the flood or spot varnish, the unit can be upgraded with a UV dryer and/or aqueous dryer.

With the new in-line module, operators can see the results immediately and make any corrections, if required, in order to achieve the desired effect. This eliminates the high expense and job delays when varnishing is done off-line and the entire job has to be reprinted if the end result is not acceptable.

Substrates the module can varnish include self-adhesive label materials, coated papers, unsupported films and coated paper board.

The web varnishing module was launched at last week’s Labelexpo Americas 2014 and will be commercially available from early 2015. A Xeikon 3500 featuring the new web varnishing module was running in the Package Printing Workshop feature area at Labelexpo Americas 2014.

Filip Weymans, director of business development and marketing for labels and packaging at Xeikon, said: ‘The label and folding carton industries employ a wide range of varnishes, from matte to super gloss, and these can have a huge impact on the appearance, feel and quality of the final printed product.

‘We are constantly expanding the components of our label and packaging “suites”, which include defined sets of software, equipment, consumables and/or substrates to complement our digital presses. This enables our customers to pick and build the best digital production solutions for their specific business needs.

‘The web varnishing module is an important addition to our suites, enabling further optimization of the processes and workflows used by printers and converters. We are convinced that the ability to apply spot aqueous varnish makes the module the ideal fit for folding cartons, which require varnish-free areas for glue strips and production data. The module is an extremely compact solution to apply spot varnish. In addition, we expect most users to also install the optional cutter and use the Xeikon stacker to create a phenomenally efficient production line.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.