Automation in the labels and packaging industry

‘MPS strongly believes that automation is the future, as it is becoming harder and harder to find and keep skilled operators today. With our own presses being equipped with maximum automation, combined with the state-of-the-art systems of our partners, we’re making life on the print shop floor much easier.’

Bert van den Brink, technical director, MPS

‘In the last decade, computer and communication technology has dramatically changed. The change in technology is that it is becoming affordable, reliable and accessible. As for reliability, it is far better than human control – today the most crucial operations are monitored by electronic systems – just think of air traffic control, for example. The label and packaging industry will also embrace the technology advancements just as other industries do. Depending on the type of business, think of “lights out production” with no or very few people controlling production. Today, certain thermal labels are already produced this way. Or imagine the benefits for label converters where people are boiling with creativity to create solutions for their customers rather than being occupied with monotonous work that is better handled through automated processes. Automation will allow label and packaging printers to perform their job better, to be creative and to excel in what they do.’

Filip Weymans, vice president, marketing, Xeikon

‘People talk about 100 percent automation, but we will never reach that. Twenty percent is better than zero; 40 better than 20, etc. If you automate what you can, you are already better than before. An automatic gearbox is better than a manual gearbox. But that doesn’t mean you have a self-driving car. That is sometimes the expectation and we need to be careful. But if you jump on the train today it will bring you an advantage. We will never be able to solve every individual print issue, and so many processes and systems are bespoke which makes it much harder to bring in automation. Automation will first be found in the things that are standard. Don’t expect automation for hot foiling or duplex printing. Logic dictates that we will start where find the most standardization and most simple processes. If you have unique machines and processes, perhaps you can automate about 20 percent of production.’

Geert Van Damme, managing director, Cerm

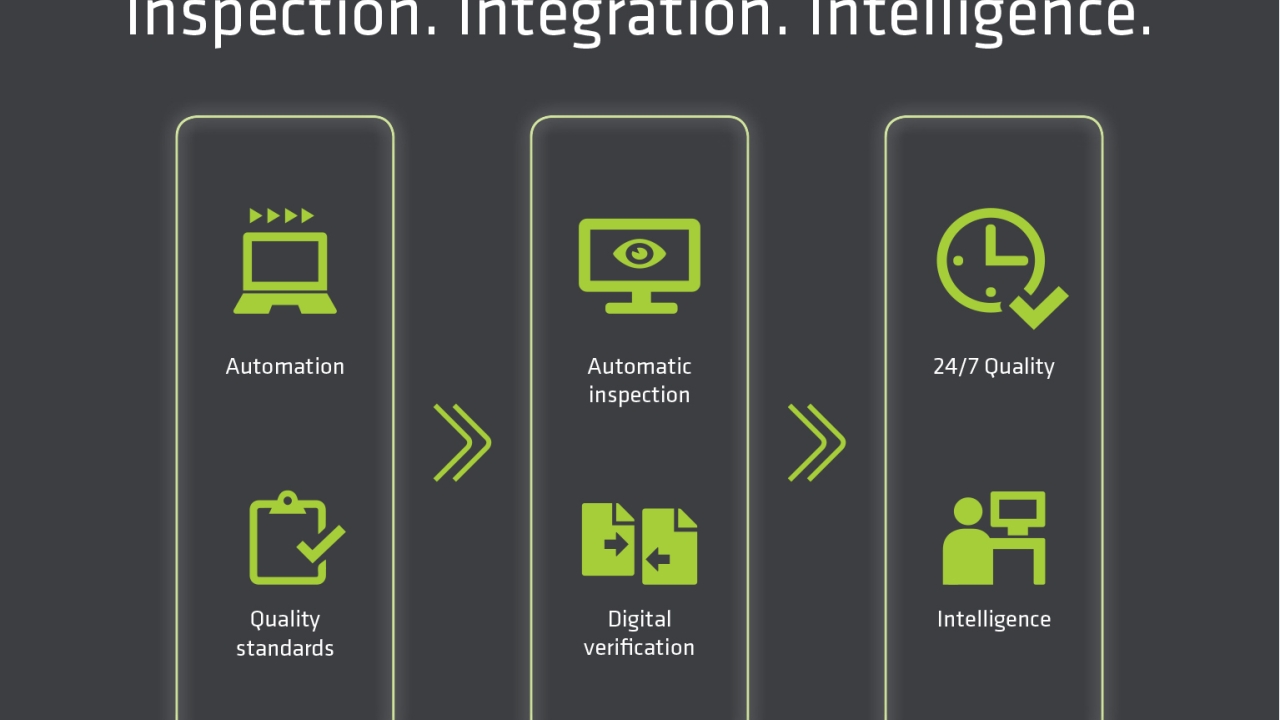

‘There is an unmistakable correlation between the level of work ow automation and the efficiency in dealing with today’s stringent label production requirements. The market demands short production runs of many different design variants to be supplied just in time at uncompromised and consistent print quality. Consequently, work ow automation will make the difference in capabilities and ultimately in profitability for label converters. This is already the case today, but rest assured that this will be even more the case in the future. Every label converter, no matter big or small, has already implemented some level of work ow automation. However, the role of automation will expand and include business system integration and communication between people, systems and devices across departments. Data will have to be shared and used throughout the entire process from order entry to loading dock and even beyond. When looking at the process from the perspective of the label buyer, you want integration from brand ideation and design up to the shop shelve. An integrated work ow platform with internal and external stakeholders involved and engaged has a direct and substantial impact on the overall lead times. Tangible benefits for the label converter are maximized device utilization and error reduction. Workflow automation in the future goes beyond automating repetitive and mundane operator tasks. It will be all about streamlining communication between customers and suppliers. Given changing market requirements, workflow automation is your best bet on driving lead time and order to cash efficiency gains.’

Geert De Proost, director, software engines, Esko

This article appears in L&L issue 5, 2017, and can be read online here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.