Beyond a clean web

One of the main barriers to the printing-press specific overall equipment effectiveness (OEE) in the label printing industry is loose contamination present on the material to be printed. There are many sources of contamination, all of which are difficult to avoid. The three key sources are contamination that is already present on the new roll of material to be loaded on to the press, contamination that is introduced on to the web from the environment or printing press itself, and contamination that is generated by operator activity and movement that disturbs the ‘dirty’ air in the immediate vicinity of each print station. Whatever the source of contamination, the direct result can be a costly stoppage to production to clean down the press, or a requirement to re-print labelstock that has been identified as scrap.

While many technologies have been used over time to combat the issues of contamination, the technology known as Contact Cleaning has become the preferred method of contamination removal for many, as both customers and the label press manufacturers have integrated this solution in to their machines. Contact Cleaning uses a specially formulated cleaning roller which runs in direct contact with the moving web. This roller collects all particles down to the microscopic level from the web, and immediately transfers them on to a layer of adhesive which has been coated on to a roll of paper or plastic. As soon as this layer of adhesive is completely covered with the collected contamination, it can simply be removed from the roll, to reveal a new layer underneath. Web cleaning is, as its name suggests, a process that is dedicated to deliver a clean web for printing by the removal of contamination from the web. However there are numerous other benefits to a label printer which can be derived from the installation of an effective web cleaner.

Long-term efficiency

A key component of any press is the anilox roll, whose performance is largely determined by the cleanliness of the cells. To clean contamination from the web removes one variable from the list of contaminants that can sit in the cells of the anilox roll.

Dust in the air, substrate fragments and other debris can all be carried into the electrode assemblies of the corona treater. If they accumulate, they can eventually clog the exhaust path of the treater and reduce the air flow rate – all leading to inefficiency of operation and a need to clean the treater. Web cleaning can significantly contribute to the long-term efficiency of the corona treater.

The key benefit of the contact cleaning technology is the permanent collection of the contamination on the adhesive layer. This presents a label printer with the opportunity for analysis. By analyzing the contamination for type, size and frequency, a company can identify the source of the contamination and implement procedures both internally and with suppliers to eliminate or significantly reduce the problem at source. If managed effectively, this analysis can enable the implementation of process and material control measures which in turn delivers both operational and financial positive gains. An example of this might be the identification of a certain type of clothing worn by operators, the solution being to eliminate such clothing from the immediate environment around the press. Equally, fragments of particles from pallets or other media for transporting the reels of material found on the adhesive layer of the web cleaner might lead to a cost-effective change in materials used to transport the material.

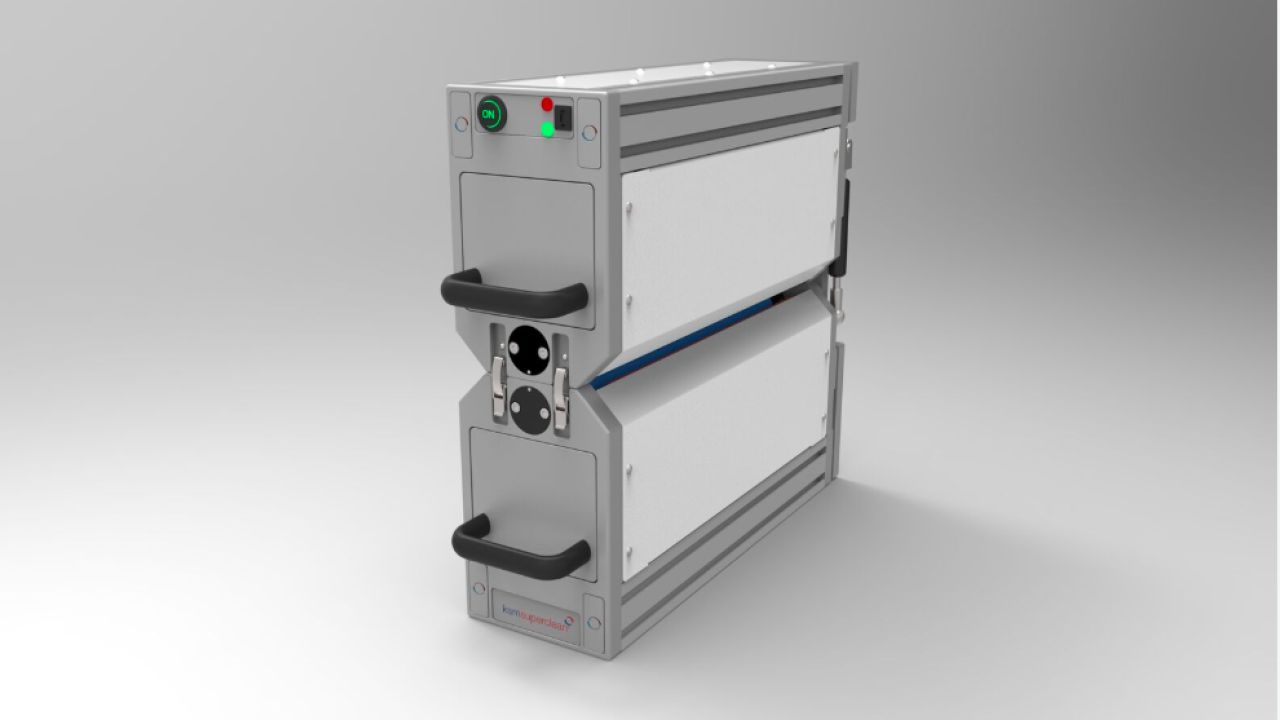

The good news for any label printer who wishes to explore the potential for contact cleaning as an effective technology to capture and analyze contamination is that it can be evaluated by using simple hand-held cleaning units. KSM Superclean supplies a free ready-made kit to any printer to enable contact cleaning technology to be evaluated in the production environment on actual labelstock. The Superclean Particle Assessment Kit is designed to be simple and safe to use, and enables the printer to gain an immediate understanding of the function and effectiveness of the technology, not only as a web cleaner, but also as a provider of benefits to the label printer beyond a clean web of material.

The article has been written by David Westwood, sales and marketing manager at KSM Superclean.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.