The bling factor

When it comes to health and beauty product labels, embellishments are non‑negotiable. Technology today not only offers the ability to create intricate embellishments but also offers sustainability benefits

In the dazzling world of cosmetics and beauty, spotting a product with packaging that does not include embellishments is almost as rare as finding

a unicorn.

Brands are not just settling for shelf appeal, they are aiming to catch the elusive eyes of shoppers navigating through a sea of beauty products in a supermarket. Special effects and finishing touches on beauty and cosmetic product labels turn packaging into irresistible works of art. Adam Frey, director of North American sales for Wausau Coated Products says that the cosmetic and healthcare industries,

like many, are always looking to create an emotional response with the buyer to drive purchases of their products. Label embellishment is one of the ways to create

that connection.

‘If you can connect with your buyer in a few seconds because you personalized or customized the label material with a specific foil emblem or highlight a feature or benefit of the product with varnishes or texture, you have a much

better chance of that consumer choosing your product over other packaging that lacks these qualities,’ Frey says. ‘Quality, special ingredients, awards and safety are just a few of the features of a product that can be accentuated with the use of embellishments.’

For example, hygiene and beauty brand Dove’s classic dove logo in gold embellishment shines against the backdrop of a white label on almost all of its products. High-end skincare brand L’Occitane integrates gold and

silver metallic foils into its label design, enhancing the packaging’s appeal. Popular beauty brand Pixi makes healthy use of metallic accents in delicate details on its

labels over soothing pastel hues, soft pinks, mint greens and calming blues.

Ryan Chai, strategic account solutions specialist at Nobelus, says: ‘In the realm of cosmetics and health labels, there’s a long-standing emphasis on luxury and quality. Presently, there’s a discernible shift towards designs that are both minimalistic and impactful. The allure of foiling, characterized by its reflective quality, provides a distinguished highlight to streamlined label designs. Furthermore, there’s a mounting interest in holographic and multi-faceted foiling techniques, capturing both a sense of premium craftsmanship and a contemporary edge.’

Design agency Kingdom & Sparrow’s managing director Kieron Weedon agrees: ‘We’re seeing a real polarization

of approaches to embellishment in the healthcare and cosmetics industries. On the one hand, is the minimalist approach that focuses on clean beauty - often also used

to denote a more premium, luxury feel. It reflects the consumer trend for authenticity and simplicity. On the other hand, there is a shift to a much more playful and joyful

space – for consumers that embrace the glamor and excitement of beauty routines – these embellishments are often much more tactile, encouraging people to play and

touch products.’

FINISHING TECHNIQUES

Finishing machine manufacturers are developing technology to keep up with the ever-evolving demands of brand owners. These machines not only offer aesthetic

labels but also come with automated variable finishing options on labels along with material‑saving capabilities.

Iosu Álvarez and Eider Lizarbe of Lemugroup explain the two major trends in label embellishments. The first is the

specialization of labels that are increasingly challenging to manufacture and visually appealing. This is mainly achieved through eye-catching finishes that include holes in the labels or the use of multiple labels with different materials. The second trend is automation and digitalization of production for speed and accuracy. In this context, the incorporation of digital inkjet varnish for greater homogeneity and productivity stands out.

In response to these market trends, Lemugroup presented at Labelexpo Europe 2023 the LI220RFID, a machine that

enables the insertion of luxury labels and the integration of RFID technology at high speeds, all with spectacular registration.

In addition, with a focus on automation and consistency, Lemugroup also introduced an inkjet embossing varnish

module (MI350) as part of its MA350+ machine. This module demonstrates high-speed productivity, ensuring no labels are lost during machine stops and starts.

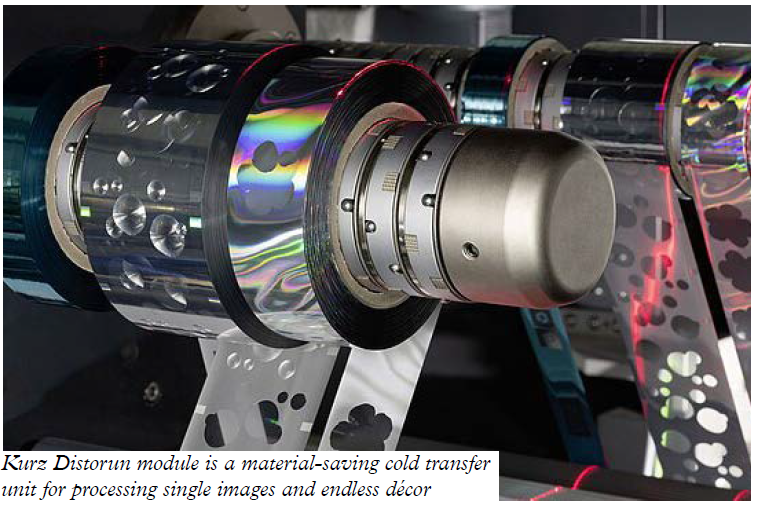

Actega EcoLeaf metalization system uses a donor roll of nano-metallic flakes attracted to a printed trigger image. Kurz offers its DM-Uniliner 2D/3D digital embellishment systems and the Distorun module, a material-saving cold transfer unit for processing single images and endless décor. It operates by reading a print mark on the web and positioning the images in relation, at the same time monitoring and syncing with the speed of the press.

Kurz also offers an inline metallization technology developed specifically for the Xeikon toner press, using a part-cured ‘tacky’ toner to adhere the metallization effect to the substrate.

An interesting decoration technology for shrink sleeves is by Pantec, which offers its Cheetah N rotary embellishment system for applying single 3D images to shrink sleeves. Such effects cannot be achieved on shrink sleeves by embossing. The customized 3D images are applied to the

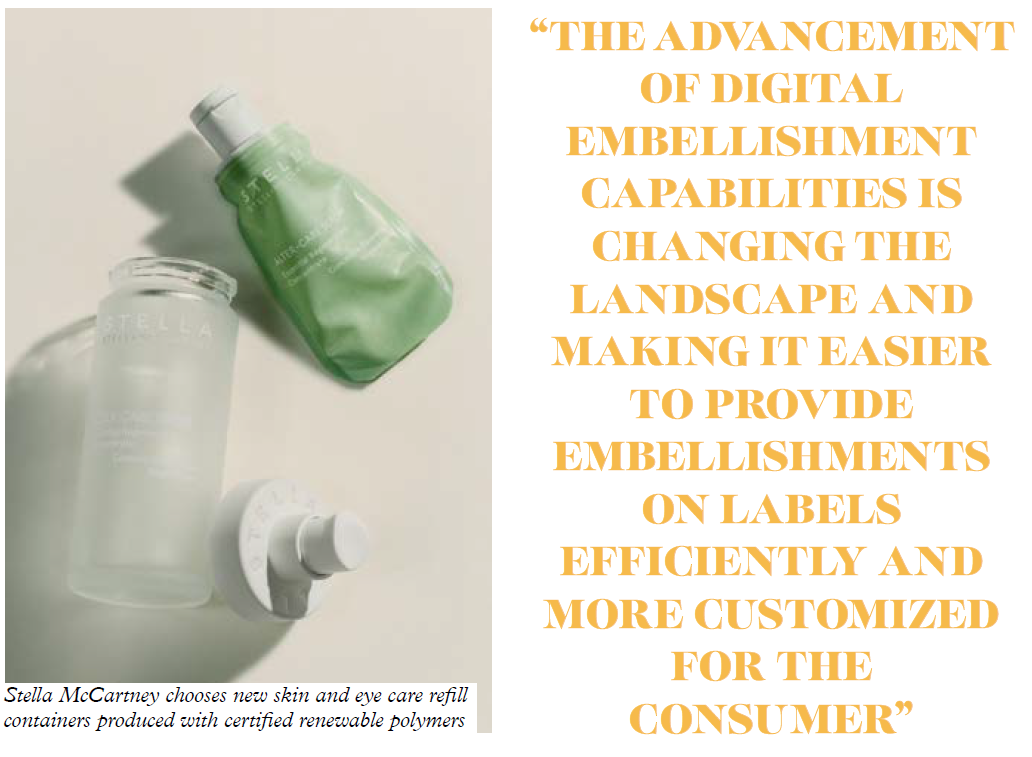

shrink sleeve by heat and pressure from a carrier film at up to 20 images a second. Wausau’s Adam Frey adds: ‘Without a doubt, the advancement of digital embellishment capabilities is changing the landscape and making

it easier to provide embellishments on labels efficiently but more importantly personalized and customized for the consumer.’

He points out that Wausau is seeing interest in pressure‑sensitive label materials that can play well with new digital forms of embellishment. Customized pressure-sensitive materials that provide the right base to allow these emerging technologies to function and provide value on a variety of surfaces are key to maximizing options for high-end cosmetics and healthcare products.

FACTORING IN SUSTAINABILITY

Christophe Dujardin, global business development manager of sustainability/cold transfer at Kurz highlighted at Labelexpo Europe 2023 that Kurz transfer products are 100 percent recyclable. Any metallic or printed transfer finish from Kurz on paper, cartons, labels and traditional plastics can be sorted, recycled and re-purposed within today’s supply chain.

According to Dujardin, it is a common misconception that foil is transferred to the substrate during hot stamping and cold transfer, creating a composite (laminate) that is difficult or even impossible to recycle. But that is not the case. Although foil is used for both processes, it only serves as an intermediate carrier for Kurz finishing products. The actual finishing is a sequence of ultra-thin varnish or metallization layers separated from the intermediate carrier in the machine and transferred to the material to be finished by heat and pressure (during hot stamping), or pressure and adhesive (during cold transfer). The coating itself does not affect the recyclability of the product. Plastic packaging with finishes from Kurz can be mechanically recycled, coated paper and cardboard can be recycled as normal or sometimes even composted.

Another factor to consider is the deinkability of paper and

cardboard in the recycling process. This means that printing inks and other surface treatments (finishes, paints and fillers) from paper fiber can be dissolved so that new paper can be produced from the cleaned fibers. The International Research Association for Deinking Technology (INGEDE) has certified Kurz transfer products, both cold transfer and hot stamped, as deinkable. The deinking residue is usually used thermally to generate electricity and process heat (steam) in paper mills.

Kurz also picks up embossed PET carrier material from the

finishing plant as a part of its Recosys program to produce PET recyclate for the plastics industry.

And of course, sustainability starts with the substrate to which the embellishments are applied.

‘With the availability of recycled or alternative content papers and films paired with specific adhesives to allow for recycling downstream, the sustainable material options are growing quickly,’ Frey explains. ‘We work hard to provide these sustainable options to perform with embellishment technology the same as previous non sustainable materials, but it is not always possible. The impact can be two-fold.

On one hand, products that contain tiny defects because

they contain recycled content may be considered unacceptable, but for others seeing those defects confirms they are making a sustainable buying decision and creates that emotional bond to drive a purchase.’

REFILLABLE PACKAGING

Cosmetic brands are considering refillable packaging to reduce their carbon footprint. Several beauty and wellness brands offer flexible packaging refills that are lighter in

weight and easier to produce in contrast to complicated rigid packaging.

Weedon says: ‘Sustainability is high on everyone’s agenda. But that’s not just a shift from recyclable and eco-friendly

products, but also refillable ones. That means harder wearing finishes that can last longer on the packaging that will live in bathrooms for much longer periods.’

One such beauty product brand Stella McCartney Beauty joined forces with manufacturing company Sabic and three

French plastic converters (Texen, Leygatech and STTP Emballage) to create a set of new skin and eye care refill containers produced with certified renewable polymers from

Sabic’s Trucircle portfolio. The containers have already been introduced in the market in North America and the United Kingdom.

Flexible packaging refills can also be increasingly observed in everyday-use hygiene product brands as well such as

detergents, liquid soaps, shampoos and lotions. Dettol, a Reckitt brand, is among the leading players in hygiene products that offer refills in flexible pouches to reduce

packaging waste.

Players such as Nobelus are also working towards the shift: ‘Sustainability transcends being a mere industry buzzword for Nobelus; it represents a core commitment,’ Chai says.

‘In response to the sector’s increasing demand for environmentally conscious alternatives, we have pioneered the development of films, notably our EcoElement range, that are compostable, yet do not sacrifice aesthetic appeal or functionality. Additionally, our dedicated R&D division is ceaselessly exploring strategies to curtail waste and reduce our carbon footprint during production phases. Anticipate further innovations in our product offerings in the near future.’

When determining embellishments, it is crucial to ascertain alignment with the brand ethos, Chai highlights.

While the allure of cutting-edge designs is undeniable, the end product must resonate seamlessly with the brand narrative. Furthermore, it’s advisable to adopt a long-term perspective, favoring materials and finishes that offer enduring quality and aesthetic relevance.

Additionally, it is important to ensure that the design, beyond its visual appeal, is feasible from a manufacturing standpoint. This ensures that production remains streamlined, is cost-effective and aligns with branding objectives in the long haul.

Weedon suggests simplicity in design: ‘As packaging becomes hyper-personalized, for example with Schwarzkopf’s SalonLab&Me products, consumers’ names

and personal products are added to the branding. This means embellishments are kept clean and minimal to allow for bespoke additional features.’

And thanks to new technology, packaging has become a key part of the brand experience - not only offering something visually and tactile but also building on brand stories. QR codes have become the simplest way to allow consumers to access more information about a product, but AR and packaging that change color to indicate if it’s running low, is becoming increasingly prevalent.

Kingdom & Sparrow’s work with Ethica CBD is a great example of how QR codes can educate consumers on an unknown category such as CBD healthcare.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.