Designed to succeed

The packaging design community tells David Pittman about its relationship with printers and converters, and how this is central to breeding creativity and innovation, and getting new products to market.

For the global packaging design community, the relationship between it and the printing and converting industry is integral to getting packaging from the drawing board to the shelf.

Guillermo Dufranc, of Argentinian graphic and structural packaging design house Tridimage, says: ‘The relationship between designers and converters is inevitable. We need each other.

‘Every design process should start with as much information as possible regarding the technological process. It has vital importance since the client expects to get what they have seen on the screen or, preferably, in a mock-up. There are many details that can't be displayed in a sample and you will only obtain them in the final production.

'A fluid communication between designers and converters guarantees that the final product meets or, even exceeds, expectations.’

For Kevin McConkey, co-founder of Grip Design in the US, the relationship is symbiotic. ‘They are the ones that are purchasing the latest technologies, so are the ones that know what it can do. By working closely together we know what can be achieved, rather than designing something that is then forced upon them.

‘This works both ways as having designers question their technology allows to uncover new applications that can be achieved with it.’

‘As the starting point in the creation of a successful product, design has to work together with the printer's resources, with their innovations and substrate materials, technical knowledge and partnerships to improve artwork to benefit the result, product, client and consumer,’ says graphic designer Fidel Anaya, of Mexico’s Anaya Graphic.

‘We have to be close to them, so we can understand their capacity, have a fluent dialog with salesmen, fit to budgets.

‘You can't design without knowing the resources you count on to give wings to your design, and if you don't know the equipment you can hardly understand the importance of what you are doing. If you bake you must know the oven.

By knowing the processes and equipment, you will be able to design successful packages using all the resources offered. With every visit to a pressroom, we get experience from their technicians and how they take advantage of their equipment.’

Pressrooms are a useful training ground for Ken Du of China's Graphic Solutions, who says: ‘If I hire a new designer who does not have any knowledge on printing processes, I will send them to a pressroom for training.’

Cornerstone Strategic Branding’s Keith Steimel, chief creative officer of the American firm, outlines how it take several factors into consideration from the start of the design process, including the print methodology, substrate, number of colors to be used, the printing of multiple SKUs in combination on a single sheet and need for artwork to print at various printers, possibly using different methods.

He says: ‘By taking these factors into consideration early on, we can ensure that we create designs that will work across all processes and platforms. Since many of our clients use multiple printers, we take a look at the strengths and weaknesses of each of them and take those factors into consideration so that we can put our best foot forward.

‘By considering the technical aspects in the concept stage, it also allows us to develop creative solutions for technical issues that are inherent in every project.

'For example, building in traps and considering the impact on the design instead of having a converter apply them when they get the files. By considering all factors from the beginning, we avoid any surprises and retain control of the final look of the printed piece.’

Du says: ‘Artwork design is very important for every further process, from printing, die-cutting, folding and gluing. A small mistake at the design stage will cause big issues, such as material waste and make-ready times.

‘When a designer is preparing an artwork, a printer’s specification is very helpful. From the design agency, to printers and convertors, good communication will improve both efficiency and quality.

Dufranc adds: ‘We always, and I mean always, contact packaging printers and converters before designing. The first step of a creative process is to know what the printing technology is and also the possibilities and constraints as well.

‘Designs should be conceived according to the printing process. This is the only way to get what we have imagined and what we expect to see printed. Designers are meant to prefigure packaging designs, and converters are the ones who will bring them to reality. Both tasks are equally important and we need to work closely together in every production stage; from the beginning at the pre-press floor to when overseeing the first run.’

Other players in the supply chain are likewise as important to the design community, although they may not interact directly.

Du says Graphic Solutions utilizes the relationship printers and converters have directly with their supplier partners to stay abreast of the latest happenings across the supply chain, as does Anaya Graphics.

Fidel Anaya says: ‘With material suppliers we get in touch through the printers’ salesmen, as knowing innovations allow us to be original and use those resources first to create outstanding package designs.’

‘We collaborate with clients when they need to choose the material that best fits the product,’ says Dufranc. ‘At Tridimage, we create structural and graphic design, so substrates and materials are the pillars of our projects. Being constantly updated with the latest innovations propels our work while enabling suppliers to add more value to their products.’

Keith Stetler of Stephen Gould Corporation, adds: ‘It is very important to keep up on all of the new paperboards introduced, as well as flexible substrates. The structure of the package is very important. If you make a mis-step, and choose the wrong material for the structure, all of the beautiful artwork won't correct this. It is also important to understand the different effects specific flexible materials and paperboard will have in conjunction with inks and graphic designs.’

The relationship with suppliers of finishes is also important to designers, even if, again, it’s not a direct partnership.

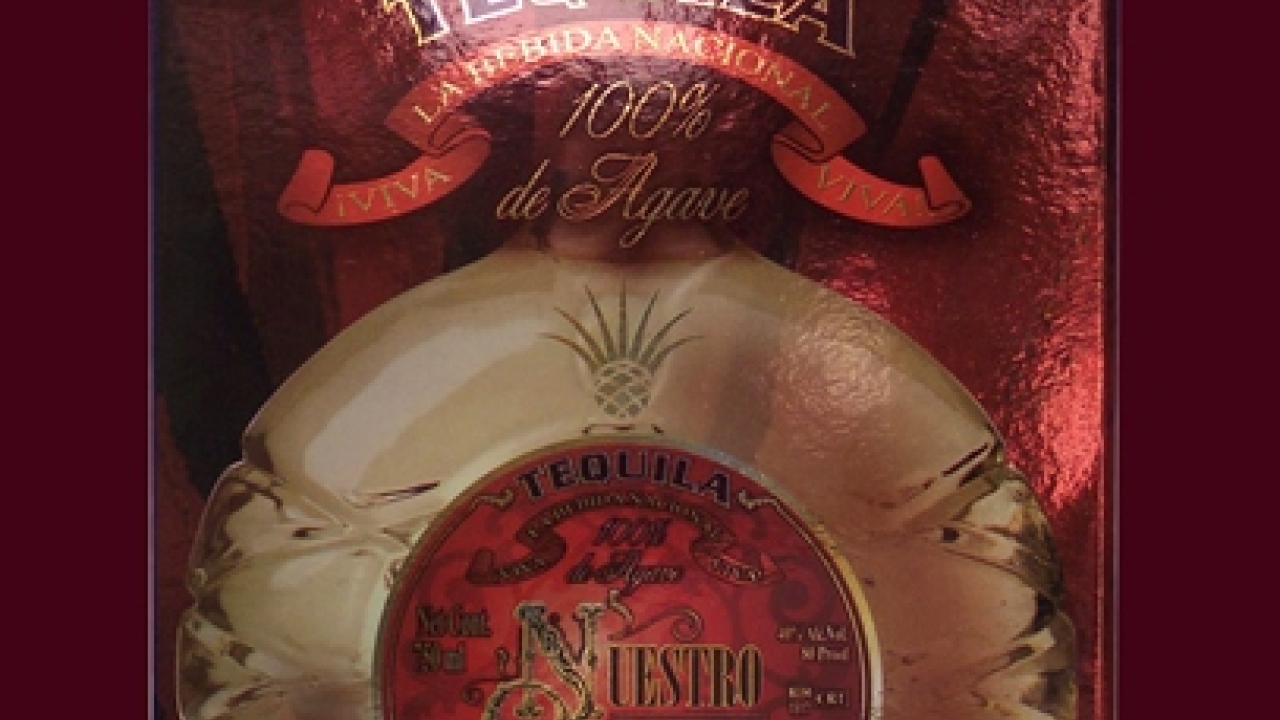

Dufranc says: ‘Finishes such as foils, UV gloss spot, embossing, glitter or metallic inks are the most magical part of any packaging design.

‘We tell the client how wonderful the result will be and we all long to see it implemented. We generally see how these amazing products change the whole brand perception when they are finally printed. In this case it is important to be constantly updated with the latest technologies and trends to give that special aura to the brand and make more desirable and valuable packaging. Moreover, finishes raise quality perceptions and can justify price increases without losing credibility.’

McConkey says: ‘This gives us insight on the latest happenings, and a lot has changed in the market in recent years. Textures and structures have come out that we need to know about.’

Stetler says: ‘I rely heavily on the printers I have established very long standing relationships with to keep abreast of all of the new ink products and quality of the products. I will work closely with my printer to make decisions on what new innovations to present for specific packaging requirements.’

One of the benefits of sharing such knowledge is to create a design that can be fed seamlessly into the package printing process.

For Anaya this is a fluid process as, ‘we know the resources and how to prepare the artwork for them.’

‘We do our best to make our designs fit the processes,’ adds Du. ‘When the design is finished and sent to the printer, they get it and work immediately without any additional adjustment and fixing.’

McConkey says Grip creates artwork files that are easy to understand and action by the printer, and proactively works to "second-guess" any questions that might be asked, and streamline the link between design and print.

For Stetler, it is important that the structural design, as well as the graphics, fit into the workflow process of printers and converters. ‘This will have a direct impact on the cost of the final product, and cost can make or break the success of the design work in respect of getting the order to run the package.

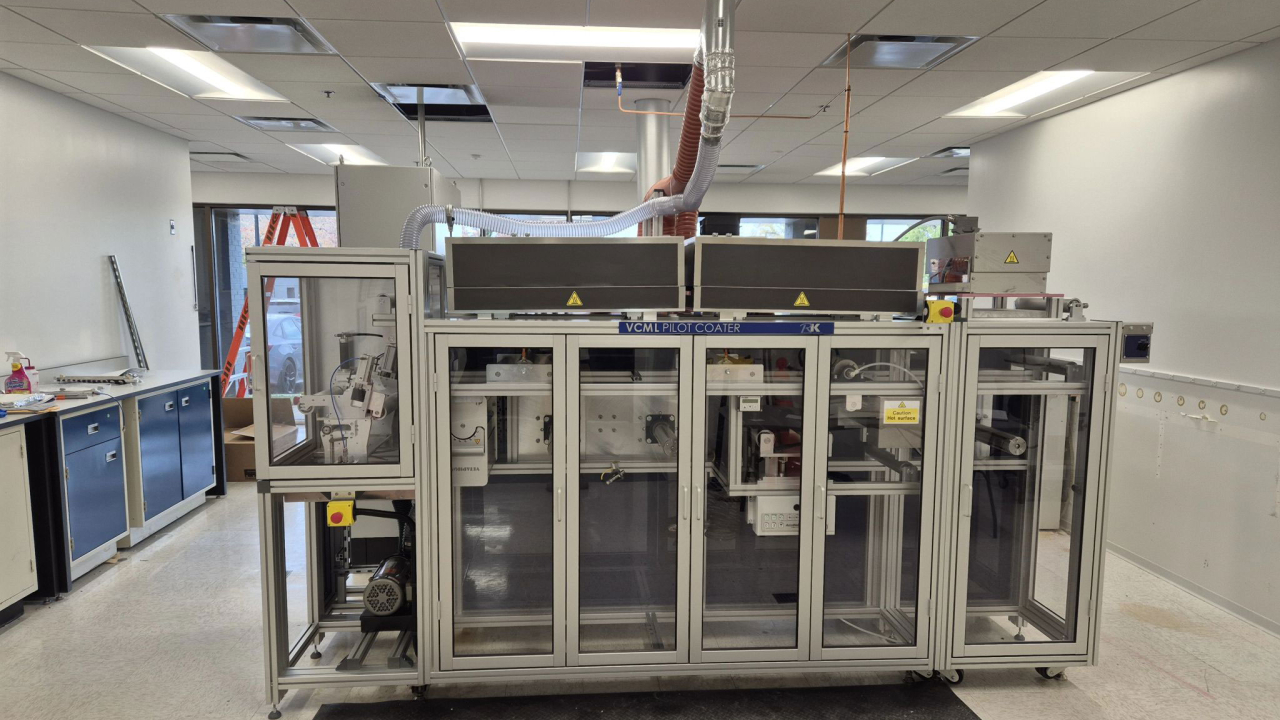

‘We have come a long way from the days of design, to sample, to approval, to vinyl die lines, to laying out artwork, to producing hard copy proofs, to sign off, to making negatives, to burning plates, to printing,’ he says.

‘The software in the last 10-15 years has made the entire process almost seamless in comparison.

'Digital files, die lines, proofs and going direct to plate has cut a tremendous amount of time and energy from the workflow, and reduced the possibility of mishaps to a minimum.’

Read more features from Package Print Worldwide here

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.