Polytag calls for UK recycling industry collaboration

The company's whitepaper outlines four key recommendations for future-proofing the recycling system.

Polytag has urged the UK recycling sector to unite behind industry-wide collaboration to overhaul the country's struggling plastics recycling system, launching a new whitepaper outlining a practical blueprint for circular economy transformation.

The London-based recycling innovator, specializing in packaging tagging and tracing technology, presented its call to action at an industry event on June 19, attended by high-profile sector players.

The company's whitepaper outlines four key recommendations for future-proofing the recycling system, emphasizing the need for barcode-level traceability and next-generation sorting infrastructure using currently available technology.

'It's time to move from rhetoric to reality,' said Alice Rackley, CEO at Polytag. 'For too long, the industry has relied on estimates, assumptions and outdated systems that simply don't deliver, and often result in widespread downcycling of valuable plastics. We've shown that item-level traceability is possible now.'

Polytag's recommendations include prioritizing item-level traceability to move away from estimates and enable real-time, barcode-level data on packaging. The company also advocates for scaling collaborative infrastructure through co-investment in detection technology and data sharing across the value chain.

The whitepaper calls for adopting next-generation sortation technologies to sort plastic by food-grade status, polymer type and brand ownership, minimizing contamination and enabling closed-loop recycling. The fourth recommendation focuses on embedding continuous innovation to adapt to evolving policy and material streams.

The push comes as Extended Producer Responsibility (EPR), the Plastic Packaging Tax, and new Recyclability Assessment Methodologies increasingly require robust, verifiable data and measurable environmental outcomes. Effective enforcement of these frameworks depends on accurate, granular data achievable only through full lifecycle traceability of plastic packaging.

'With regulation tightening and the pressure to prove impact mounting, the sector faces a clear choice: keep guessing, or get serious about data, collaboration and real results,' Rackley added. 'The technology is ready. The infrastructure is growing. What we need now is collective action to scale it together.'

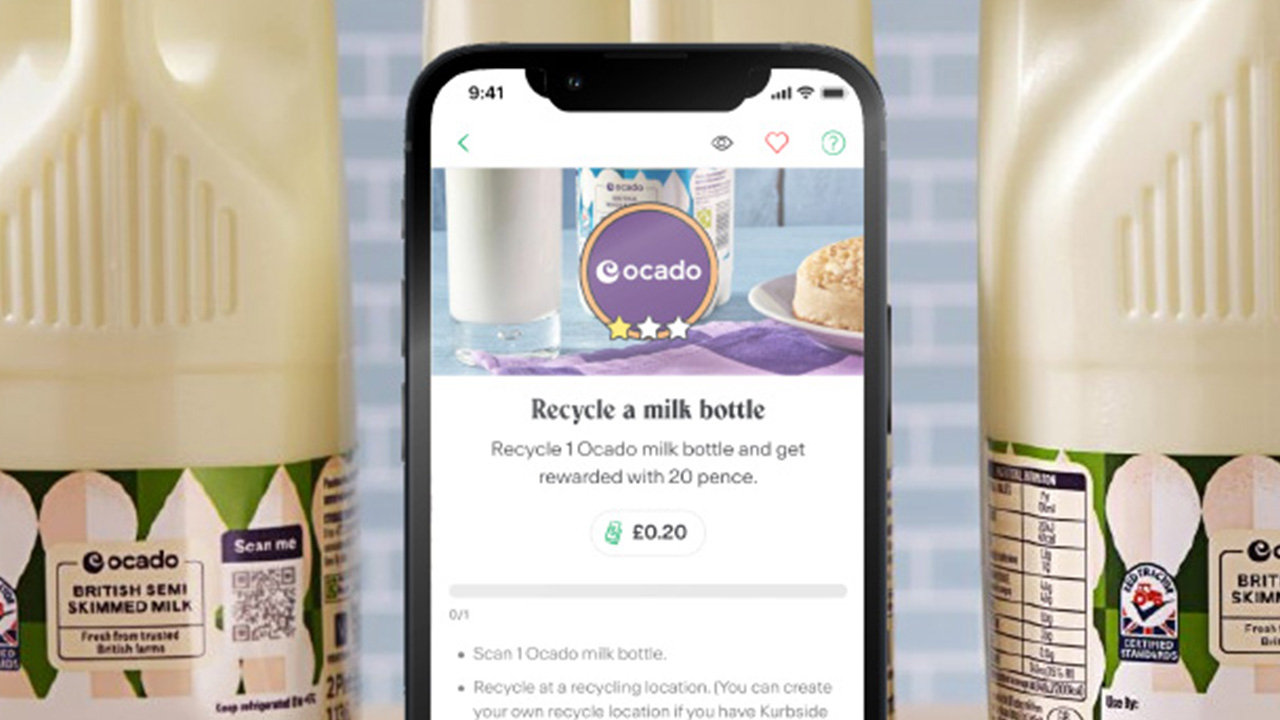

Polytag currently works with organizations including Pellenc ST, Citeo, Biffa, Waitrose and Ocado Retail to build a network of material recovery facilities capable of creating a closed-loop recycling system for single-use plastics.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.