Why employees like lean

Attracting great employees is all about culture, and using continuous improvement and lean tools demonstrate a commitment to people, and it pays off in the end.

One of the biggest obstacles to growth reported by converters and converter suppliers is finding resources. Finding and retaining employees has become more of a science since Covid, and building an attractive work environment has never been more critical. Coming from the operational side of the business, I often wonder why there is hesitancy in adopting lean manufacturing and a continuous improvement approach to running a business.

The work environment in companies without a lean and continuous improvement focus tends to have more turnover. It is less competitive because the environment perpetuates a less committed mindset to doing things correctly. The

work environment at companies that have started a lean initiative and then given up also needs help.

I have interviewed operators of companies that once had firm commitments to continuous improvement but have yet to regain focus due to leadership changes, ownership changes and the consolidation efforts impacting the market today. The common thread is that the operators miss the cultural benefits they felt in a lean organization because they believed their talents and contributions provided a competitive advantage. They had a higher sense of worth to the organization.

New generation workforce

The tangible benefits of a lean organization become more evident as we explore the needs of the next generation of workers. The stories and statistics from 10 to 15 years ago are overwhelming about lean implementation failure rates in companies. The reason for the low success factor points

to a failure to understand the disciplines and the commitment from leaders that is required.

Today, however, the heightened pressure identified as the needs of employees and the needs of the industry may finally force leaders to make that commitment. Significant alignment is identified as part of a cultural awakening required to harness the capabilities of the new generation

workforce.

The dialog about why lean is important must move from just being about an organization becoming more competitive to

developing a work environment attractive to employees.

What employees want:

• Purpose finding meaning

• Community and connection

• Growth and long-term focus

• Increased value and self-worth

• Simplification and standardization

• Specific recognition

What companies need:

• Collaboration involving everyone

• Silo elimination and process focus

• Simplification and standard work

• Employees for the long-term

• Innovative problem solvers

• Advancement of skilled work

Our next-generation workforce is telling us they strongly need more fulfillment from their work environment and better work/life balance. Specifically, leaders in organizations are burning out quicker post-Covid because they have more general responsibilities. Like all employees, leaders seek camaraderie as part of a winning team that celebrates personal success and provides nurturing.

What will help move a culture is a roadmap that amplifies how to build on the strengths of our employees, so they know they have an opportunity to grow and become great.

We’ve all heard that the best leaders must be exceptional coaches. Executives and business owners are responsible for teaching leaders these skills and paving the way to answer their needs. The next generation of workers will demand this, or they will leave. In a recent survey, over 72 percent of employees say it is essential for them to feel part of a community at work.

The answer to the workforce crisis can be found with a lean, continuous improvement focus for the employees and the leaders.

Committing to lean involves the entire company. This management philosophy promotes the concept that everyone in the company is part of a team. Solving problems and using kaizen projects to advance a solution promotes involvement and eliminates costly silos of activity.

Kaizen teams are engaged, and the participants have a sense of fulfillment, all very important to the next generation workforce. The company gains the elimination of problems by getting to the root of the issue. The investigation and elimination steps ensure the correct attention and focus are achieved quickly.

The lean tools

Lean is all about increasing an overall company’s efficiency by providing a balance of the flow of work that provides

an increased velocity of throughput. Accomplish throughput advances are mapped with a focus on bedrock foundation

elements of lean: standard work, visual management, 5S, and waste identification.

Standard work is a tool that provides continuity as well as a training reference for completing a task the best way every time. Employees are engaged to write the best standard work, and leaders use the input to solve areas that struggle with the process, thus increasing productivity.

Managing the improvement activity requires community

involvement in kaizen events focused on advancing the best process methods. Sustaining the standard work involves communication and feedback as part of the daily management approach. Shift start-up meetings and frequent follow-ups at the machine level fill the need for communication. These quick communication huddles

are perfect for employees to come together for a common purpose, solving problems and highlighting achievement.

Trying to explain all the tools of lean and all the fundamental

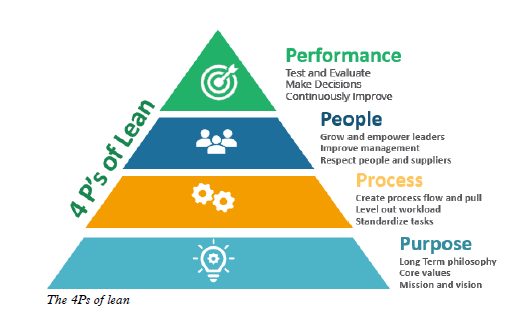

approaches to implementing lean in your company cannot be achieved in a brief article. A simplified overview is a communication about the ‘Four P’s of Lean,’ and I can show you how they resonate with our new workforce and with a cultural alignment.

Purpose: High on the list of desired traits in a company for

new employees is identifying a purpose that provides meaning. Employees want to understand that the company has a long-term vision with a commitment to that vision that includes a fulfilling work environment. It is essential to see and hear current employees talking about the positive atmosphere and to see leaders demonstrating values being communicated. They want leaders willing to share detailed information about strategy, goals and how people will be held accountable.

The foundational toolset of the House of Lean provides a

toolset of standard work, 5S, visual factory, and a focus on waste identification that communicates the commitment to vision daily. During the lean implementation phase, the training ensures the employees and the leadership teams understand how these fundamental stones are placed. The information is repetitively presented, including at the onset of each kaizen event.

The commitment to kaizen is part of a long-term vision and

commitment focused on continual improvement. The kaizen

philosophy assumes that our way of life – be it our work, social, or home – deserves to be constantly improved.

Process: Workers at every level of an organization want to see consistency and standard work. Having one way of performing a task helps individuals identify with the expectations of the job, and having one way defined and supported with documentation and visual aids can be easily shared from shift to shift in a visual company.

Using a standard approach to process problem-solving helps with consistent communication, breaking down silos of activity. The process map is often the starting point for evaluating a company simply. Having fresh eyes from multiple areas of a company and understanding the process flow is helpful in the identification of barriers in the process and stimulates collaborative discussions to fix any issues and speed up the process steps. The process approach, usually measured by time and value-added content,

eliminates silo thinking that stifles an organization.

Measuring process cycle time and process quality eliminates inconsistencies in management and actions by the workforce at all levels. Problems rise to the top visually, and leaders can help define corrective action by including the process responsible person.

Kaizen projects provide the tools to solve process issues and build standard work.

People: One of the most substantial teachings of lean

manufacturing is the reliance on people as the most versatile asset a company can help flourish. Coming out of the Covid isolation, we learned the workplace can rebrand itself as a central hub of a community of people pulling together to add value for the customers being served. Community and linkage to others are essential in the new work life.

There is a disconnect in many organizations, assuming their

workers, who complain about the amount of work, are looking for less when looking for more versatility and support to advance improvement. When we pull together a kaizen event, we typically find that the workforce is excited about the inclusion to improve things and is bold in doing the work required to advance an improvement idea. The kaizen participants use task diversity to help pull them from the mundane to a level of fulfillment for their involvement. People want to know the company will invest in them, help them learn their job, and also help them learn about the

industry they work in.

Communication is essential, and positive specific recognition is a crucial element of this communication. Visual management practices help provide a consistent method to communicate each engaged worker’s appreciation and value.

Performance: Every work team in a lean environment is

comfortable with the idea that performance is a critical element of organizational success. The workforce is anxious to know their process task is impacting results. As a result, a company needs to understand specific driving metrics that an operator can relate to from their vantage point. Leaders often talk about profits or gross margins, and an operator running a press finds it complex to draw the connection from their tasks.

Lean puts attention to metrics on time, quality and productivity. Using the visual factory tools with simple metrics displayed and maintained by employees drives a focus on performance if they are linked to the efforts and displayed at the machines.

Sustaining a competitive advantage requires an organization that can pull together company assets in a cohesive approach to generating value for the customers they serve. The roadmap to achieving the cohesive movement is chartered with lean manufacturing.

Attracting great employees is all about culture, and using

continuous improvement commitment with lean tools

demonstrates a commitment to people. The reduced turnover rates reported by lean-focused organizations highlight the benefits compared to non-lean-focused organizations. Is there any wonder why?

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.