Armor’s strategic aims

The history of Armor is that of a French industrial group dating back nearly 100 years. Starting in the production of carbon paper, Armor became the first company to develop thermal transfer technology in Europe.

With Armor Industrial Coding & Printing (AICP), the group has now positioned itself as a global leader in the design and manufacture of inked films for printing barcodes. Armor has a long history with ink, having invested in remanufactured laser cartridge production in the early 1990s shortly before launching its first inkjet cartridges in 1993.

AICP designs and coats semi-finished products in the Loire-Atlantique region in France, which are subsequently processed at international industrial slitting units. Located in France, China, India, Singapore, South Africa, Brazil, Mexico and the US, these plants are able to meet specific local demands while limiting the environmental impact of goods transport. This highlights the group’s work to expand its horizons outside France, using a co-industrialization model of manufacturing in its home market and seeking growth beyond both France and Europe in order to boost employment in France.

‘For Armor, co-industrialization means successful globalization that marries growth with respect for the company’s human values,’ states Hubert de Boisredon, group CEO and chairman.

Innovation drivers

Since 2014, Armor has focused investment on innovation within a social context, offering options to the challenges faced by modern society. This means securing the safety of goods and people alike via product traceability, a challenge squarely met by thermal transfer printing consumables production. Furthermore, the group is determined to reduce its environmental footprint by offering innovative and responsible products. Within this context, in 2016 Armor launched production of eco-friendly 3D printing filaments and is striving to improve the safety, performance and life-cycle of batteries by developing a range of current collector films, En’ Safe.

En’ Safe is made of ultra-thin aluminum or copper foils coated with a special high-tech film designed to protect from chemical attacks, reduce electrical internal resistance and improve adherence. The product has been designed to provide manufacturers with a new current collector for added security, greater performance and a longer life of Lithium-ion batteries and ultracapacitors, which are experiencing significant growth – 20 percent annually for Lithium-ion battery components and 30 percent annually for ultracapacitors. Armor is also developing technologies offering widely accessible energy via ASCA, a third-generation photovoltaic film.

However, it is experience in the formulation of inks coated onto thin film that has enabled the group to position itself as the global market leader in thermal transfer technology, the most widely used technology worldwide for printing variable data associated with traceability. Thermal transfer offers the ability to print on a wide variety of substrates, such as paper, synthetic and textile labels, and packaging films, while low maintenance, robust printers are suitable for industrial environments. This makes the technology suited to the demands of the retail, logistics and food processing industries, and more.

The business of AICP is conducted via its 15 subsidiaries and sales offices. With 50 percent growth achieved over the past 10 years, annual sales now far exceed one billion sqm of coated film. Through its team of 40 engineers and R&D researchers, the company regularly extends its product range, achieves a product conformity rate of over 99.9 percent and sets itself the objective of reducing its solvent consumption per sqm by 15 percent in five years – a target it has already achieved.

New products

AICP focuses on innovation and investment in new products, with 2017 to be a year of product development and renewal.

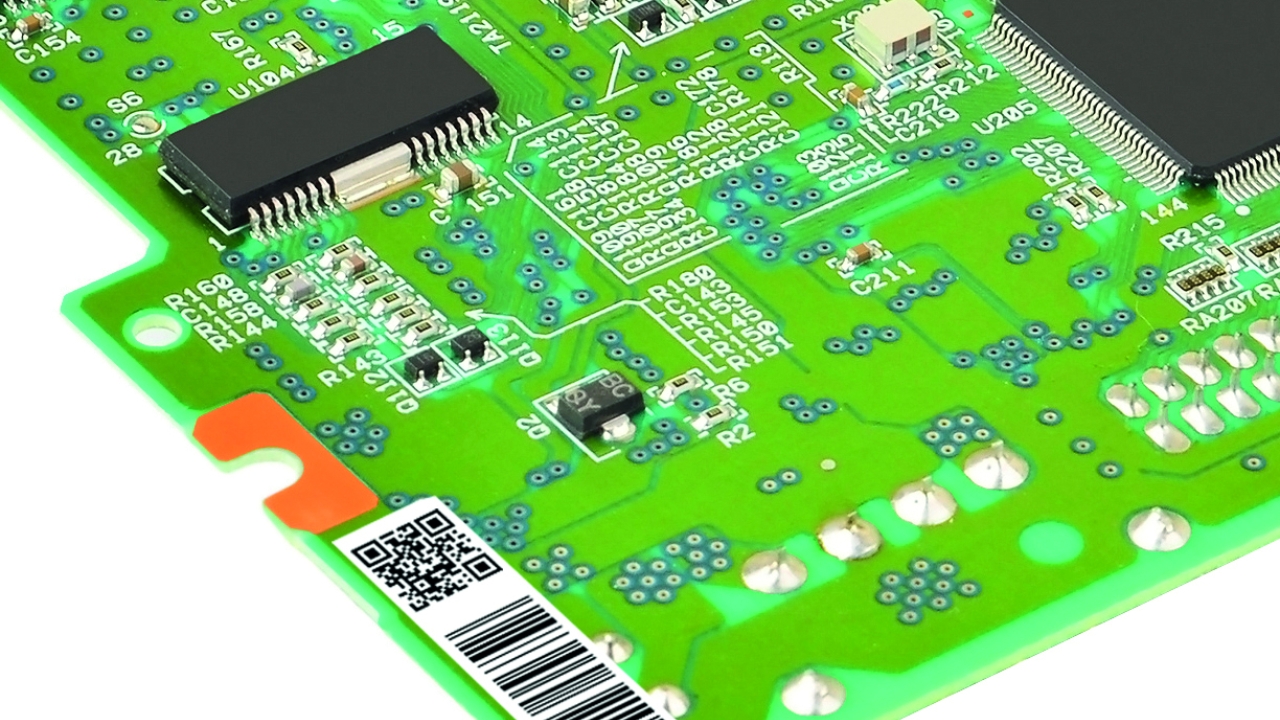

This includes a greater focus on application-specific products, and in February AXR EL was introduced, a ribbon dedicated to printed labels used in electronics products, notably printed circuit boards (PCBs) and electronic sub-assemblies. Manufactured in their millions each year, PCBs are identified using barcodes guaranteeing traceability at all times. Selecting the right label and ink is therefore crucial for guaranteeing the read quality of the print and its durability throughout the product life-cycle. After analyzing the specific constraints associated with the manufacture and use of PCBs, the Armor R&D team worked on an ink formulation offering performance levels that meet the highest demands of circuit board manufacturers. The new ribbon offers resistance to temperatures of up to 300 degrees C (572 degrees F) and to the solvents most commonly used in the electronics industry.

Compatible with high performance labels, AXR EL is suitable for all print media used on PCBs. Offering fine print characteristics, the new ribbon is ideal for printing all types of messages and barcodes with great precision, even on the smallest labels. It meets the demands of the industrial standards applicable to the electronics industry, enabling manufacturers to comply with the IPC 610-E standard (marking legibility) and the EN 50419 standard (marking of electrical and electronic equipment). Designed and produced by Armor at its Thermal Transfer Expertise Centre in France, AXR EL is available worldwide via the company’s eight roll slitting plants.

Armor is also introducing a new ribbon designed for the textile industry, AXR TX, which has been developed with the objective of printing on structured labels and to meet the demands of the numerous processes involving textile products. AXR TX produces high-resistance and high-quality prints for identifying textile products and communicating product care instructions throughout their life-cycle. The new ribbon is resistant to washing, drying and ironing processes in both the industrial and domestic environment. It produces prints of an intense black color that do not deteriorate, ensuring legibility over time. Offering guaranteed enhanced fine print fine characteristics, it is compatible with the main materials used in the industry such as nylon, polyester and satin. AXR TX conforms to numerous international standards, including Oeko-Tex certification in the textile industry.

Long-term vision and investment AICP has developed from the outset by implementing a strategy of establishing long-term partnerships, and rejecting any short-term or opportunistic approach.

Entwined in the company’s DNA is a focus on investment and innovation to ensure growth for its partners via a quality of products and services. The launch of AXR EL and AXR TX meets this desire, and helps Armor’s partners benefit from specialty markets with high added value.

A 12 million EUR (12.6 million USD) investment in 2016 in a new high-speed coating machine (see boxout) provides Armor with an additional 30 percent production capacity: a necessary volume to enable its partners to grow in all markets over the long term.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.