Making business stick

The family-run company, founded in 1928, has extensive experience in offset and book printing, and specializes in label production, including numbering, perforation, blind stamping, die-cutting, grooving and lamination.

After decades of success in sheet-fed printing of labels using offset paper, gummed paper and adhesive paper, Urlichs & Pape’s two managing directors, Ulrich Peters and Wolfgang Hohgardt, added label roll production using a thermal transfer printer as a service line. Pre-punched formats were used, which were printed only in black with just a few format variations.

However, using this format, customers gradually withdrew and moved into their own label production. This prompted Urlichs & Pape to search for a system that would enable it to print color adhesive labels.

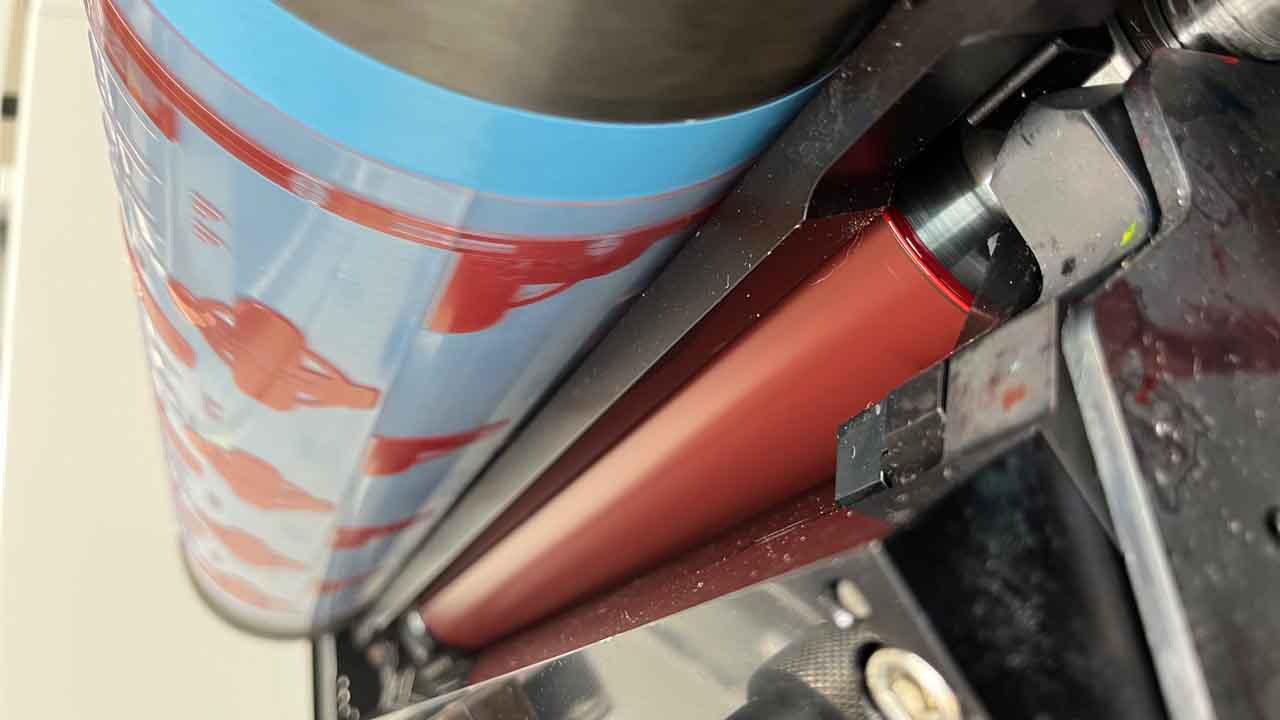

It opted for OKI’s Pro1050 5-color digital LED label printer, with the UniNet iColor LF700+ digital label finishing system. The combination enables Urlichs & Pape to print high-quality color labels and carry out further processing efficiently.

‘OKI’s Pro1050 is a very well-designed and highly sophisticated system that, in combination with the UniNet finisher, guarantees seamless, smooth production at maximum quality,’ says Ulrich Peters. ‘The rolls with the respective media types can be replaced very quickly and the consumables have a high capacity.’

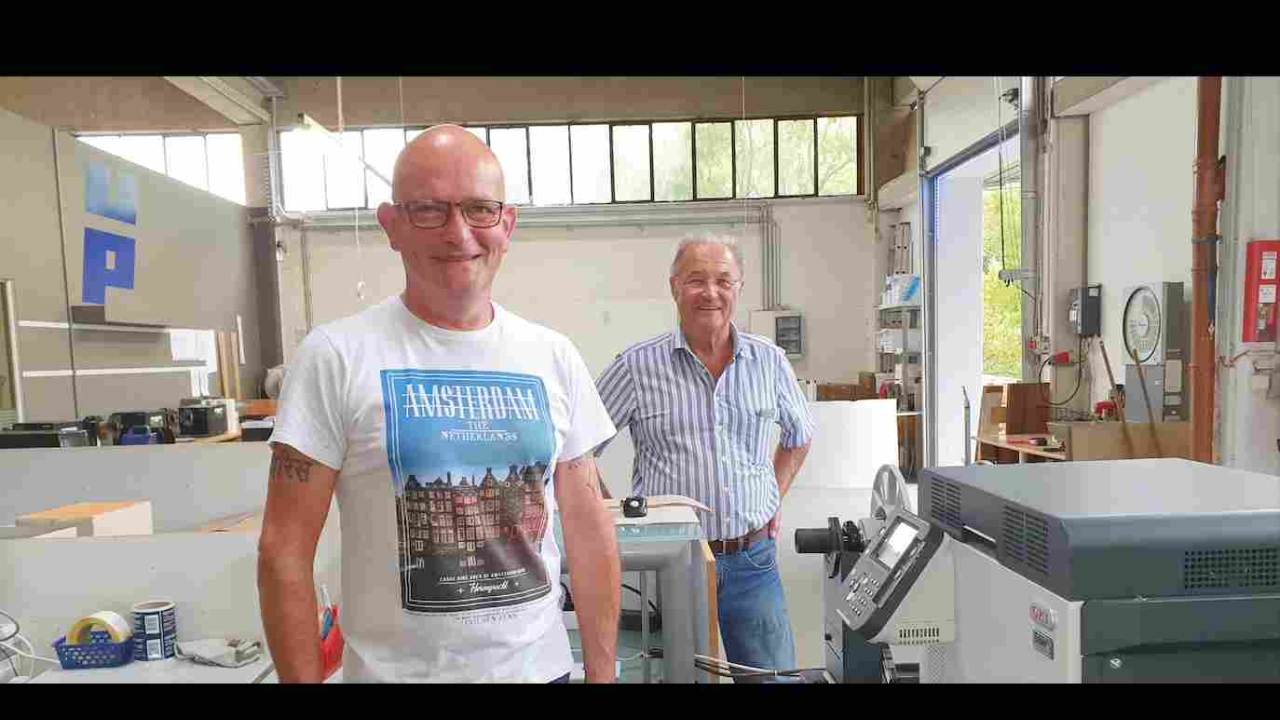

The team from Urlichs & Pape were supported in the set-up of the new label printer by its partner Faber, which handled the installation, preparation and on-site training.

However, according to Peters, much of the training wasn’t required: ‘The OKI system is easy to use and features a simple format and material change procedure, which means you can get the next job running in just three minutes. As I was already familiar with Illustrator and InDesign, I was ready to use the new system after just two days of instruction.’

Using the new system, Urlichs & Pape can now print on a wide range of media, including uncoated, glossy and textured papers, as well as synthetic materials with a variety of substrates including transparent, opaque, white or colored.

Having the option of white as a fifth color gives the company greater flexibility in the design of printed labels. White can be used as a background on transparent substrates or to create new designs on colored or metallized materials.

‘The enormous advantage of this solution is that from now on we no longer have to buy ready-made materials or punching tools,’ said Peters. ‘For the individual formats of the respective labels, I can now easily create a cutter line for the drag knife of the finisher, the matrix is removed and the product is cut and wound, moving from rows of three to one. The order is ready to ship before you know it and the customer is happy.’

Benefits

Since moving to OKI’s Pro1050 printer and UniNet iColor LF700+ digital finishing system, switching between different media has proved to be easy for Urlichs & Pape.

Efficiency has also been a big advantage, making it possible to produce more in a shorter time. Small labels in small print runs now cost less and are more bespoke, making them more attractive to customers.

‘Today’s customers no longer want sheet material as an end product, where they have to painstakingly tear off each individual label,’ explains Peters. ‘Offset printing is not able to cope with label production in this form. This is where the strengths of the OKI label printer come into play. The labels on the roll are printed in perfect color and quality. The roll then hangs in the finisher where the matrix is professionally removed and the labels are cut, separated and rewound.’

With the new possibilities offered by the OKI printer, Urlichs & Pape is now in a position to access new industries and expand its existing customer base. In particular, it is targeting industries that need labels in smaller quantities.

‘We initially contacted machine manufacturers, pharmacies, jewelers, and florists, and showed them the new possibilities we can offer,’ says Peters. ‘Bakeries and confectionery companies, which by law have to label each individual bag of food in order to specify which ingredients are contained, represent a particularly interesting customer group for us. The same applies to butchers who offer vacuum-packed meat in addition to canned and jarred produce. These products must be labeled correctly. We want to push into these small niches in a very targeted manner and are convinced that this business area will grow and generate enough volume to warrant the installation of a larger system after the start-up phase.’

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.