Shree Lamipack focuses on backward integration

Shree Lamipack is now in the process of upgrading its facilities and has made a string of investments in the last year, including a Weigang slitter rewinder with 100 percent inspection system from BST for finishing labels, and a high-speed slitting machine for jumbo rolls of thermal transfer ribbons. It also began manufacturing holograms in August 2018.

The company has ordered a Bobst press which it expects to receive before the end of this year. ‘The Bobst is a great machine and we are getting it customized according to our requirements,’ says Deepak Gupta, CEO of Shree Lamipack.

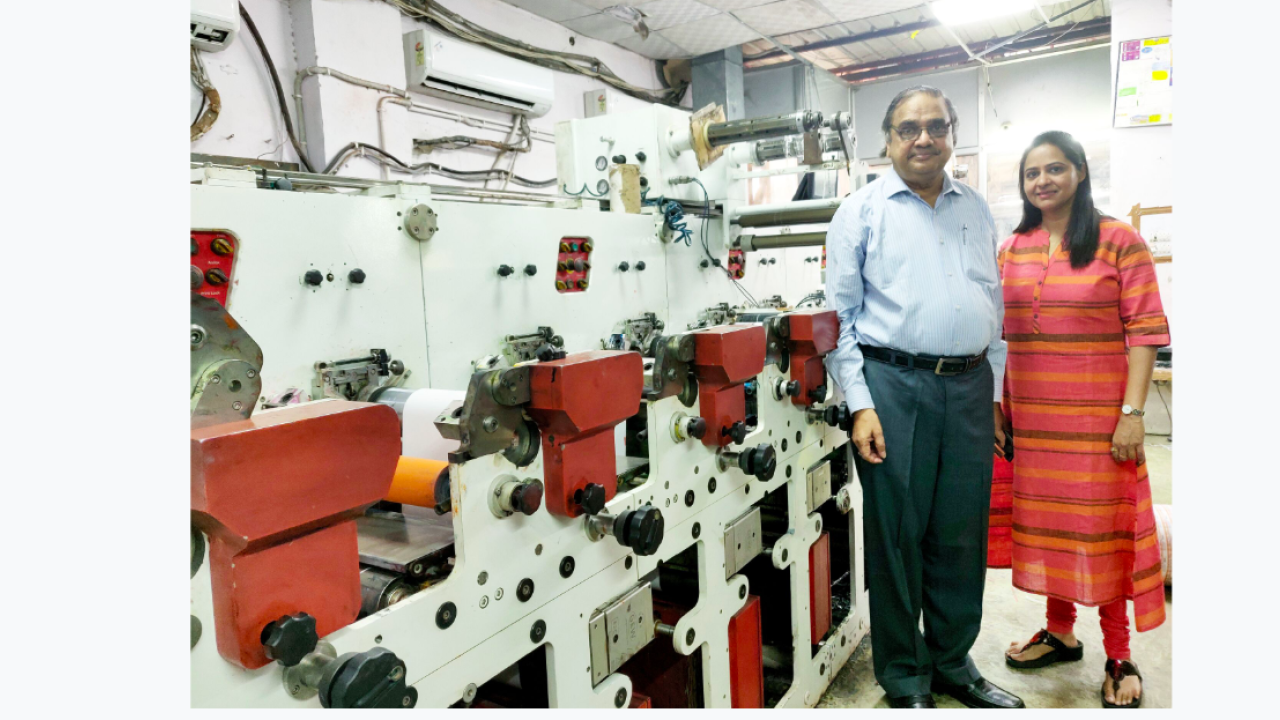

Shree Lamipack is currently printing pressure-sensitive labels on a 4-color press from Onda, 8-color UV flexo press from Multitec, two flexo presses from Jandu Engineers for up to 3-color jobs, and one RK flatbed machine for plain barcode labels. ‘While I am satisfied with my presses from Indian manufacturers, it has become important for the business to have a European press. There are certain jobs that the new press will print better than existing equipment in the plant. Also, brand owners demand to know which presses labels are printed on and printers with premium presses get a preference,’ says Gupta.

The company has also invested in a single-color off-line screen printing machine from Taiwan. Expected to be installed this year, this roll-to-roll system is equipped with both IR and UV heaters, auto tension control and auto-register.

‘We are installing the latest equipment for further penetration in the raw material segment. We are going to install three more coaters by the end of 2019. One will be a hotmelt coating unit, the other two will be dedicated to liner manufacturing,’ reports Gupta. ‘We are currently producing 500,000sqm of labelstock per month on two coaters by Indian manufacturer Jandu Engineers. Of this, five percent is exported to Bangladesh and the Gulf countries. With the new investment, we will not only increase our volume but also expand our market reach.’

Any business in India thrives on credibility, consistent quality and service. ‘We manufacture labelstock but we print on material from other companies if the customer demands it. We believe in transparency and show invoices to customers, if required. So we have built credibility in the market and this is helping us grow,’ says Gupta.

Catering to the automobile, oil, inverter and pharmaceutical industries, Shree Lamipack prints an average of 400,000sqm of labels every month. ‘Most of our jobs are long runs with lengths starting at about 10,000sqm,’ says Gupta.

Spread across an area of 25,000sq ft, Shree Lamipack is now also looking at expanding its factory space.

Security labels

Growing at 40 percent year-on-year, the company clocked the turnover of 20 crore INR (around $3 million USD) in 2018-19. ‘Almost 40 percent of the business is contributed by security labels that demand a lot of value addition and anti-counterfeiting features. We continue to increase this portfolio because it offers more job security and stability in business. Our clients like to work with us because we help them solve their problems and customize according to their requirements,’ says Gupta.

On its 8-color press from Indian machine manufacturer Multitec, Shree Lamipack is printing tamper-evident labels with spot varnish, cold foiling and lamination. It is also using specialized raw material such as thermochromatic inks and invisible UV ink, among others, to produce special effects on labels.

‘Brands have to be shown value not only in quality and turnaround time but also in service. For instance, we recently retained an inverter brand by simply redesigning their label with brighter colors and adding a few features to guard it against counterfeiting. In another case, we printed 14 languages on a thin holographic strip, making it difficult for anyone to reproduce it. It is important to make a job complicated to give counterfeiters a run for their money,’ explains Gupta.

Shree Lamipack will make its debut at Labelexpo Europe this year with focus on holographic labels, labelstock, silicone liners and thermal transfer ribbons.

Stay up to date

Subscribe to the free Label News newsletter and receive the latest content every week. We'll never share your email address.